Anti-haze window screening filtering effect testing device and testing method

A technology of filtering effect and testing device, which is applied in the field of testing the filtering effect of anti-smog window screens and testing devices for the filtering effect of anti-smog window screens. The filtering performance of anti-smog window screen materials, the comparison of the filtering effect of anti-smog window screen materials, etc., achieve the effect of simple and convenient testing process, accurate and reliable testing, quick and convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

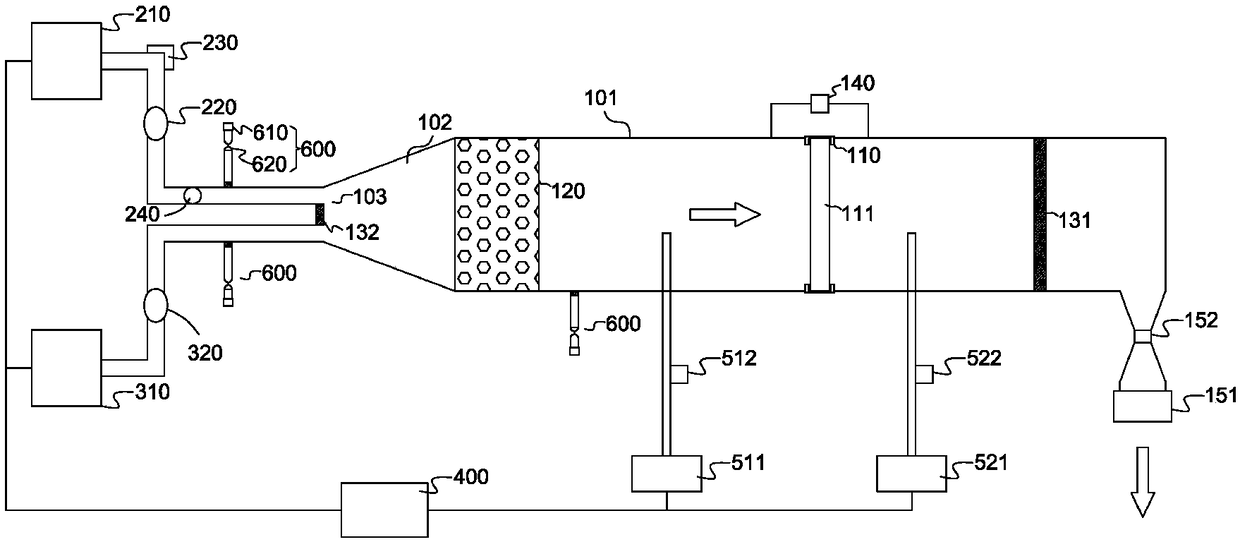

[0027] This embodiment gives a kind of optimal implementation mode, as figure 1 As shown, a device for testing the filtering effect of anti-smog window screens mainly includes: a tubular body 101 with an inner cavity open on one side, a horn-shaped diffusion part 102 with two sides open, a clamping part 110, a dispersion orifice 120, and a downstream filter 131, upstream filter 132, solid aerosol generator 210, first particle size cutter 220, heating unit 230, static neutralizer 240, liquid aerosol generator 310, second particle size cutter 320, computer Unit 400 , upstream particle concentration detector 511 , upstream particle concentration dilution unit 512 , downstream particle concentration detector 521 , downstream particle concentration dilution unit 522 and three groups of aerosol concentration control units 600 .

[0028] The larger port of the diffuser 102 is connected to the opening of the tubular body 101 , and the smaller port is the air inlet 103 . The central p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com