Heavy load pressure sensor and manufacturing method

A pressure sensor and pressure technology, applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve the problem of silicon pressure sensor being difficult to be applied, and achieve the effect of reducing the risk of failure, improving the ability to resist shock and vibration, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the following examples are based on the premise of this technical solution, and provide detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

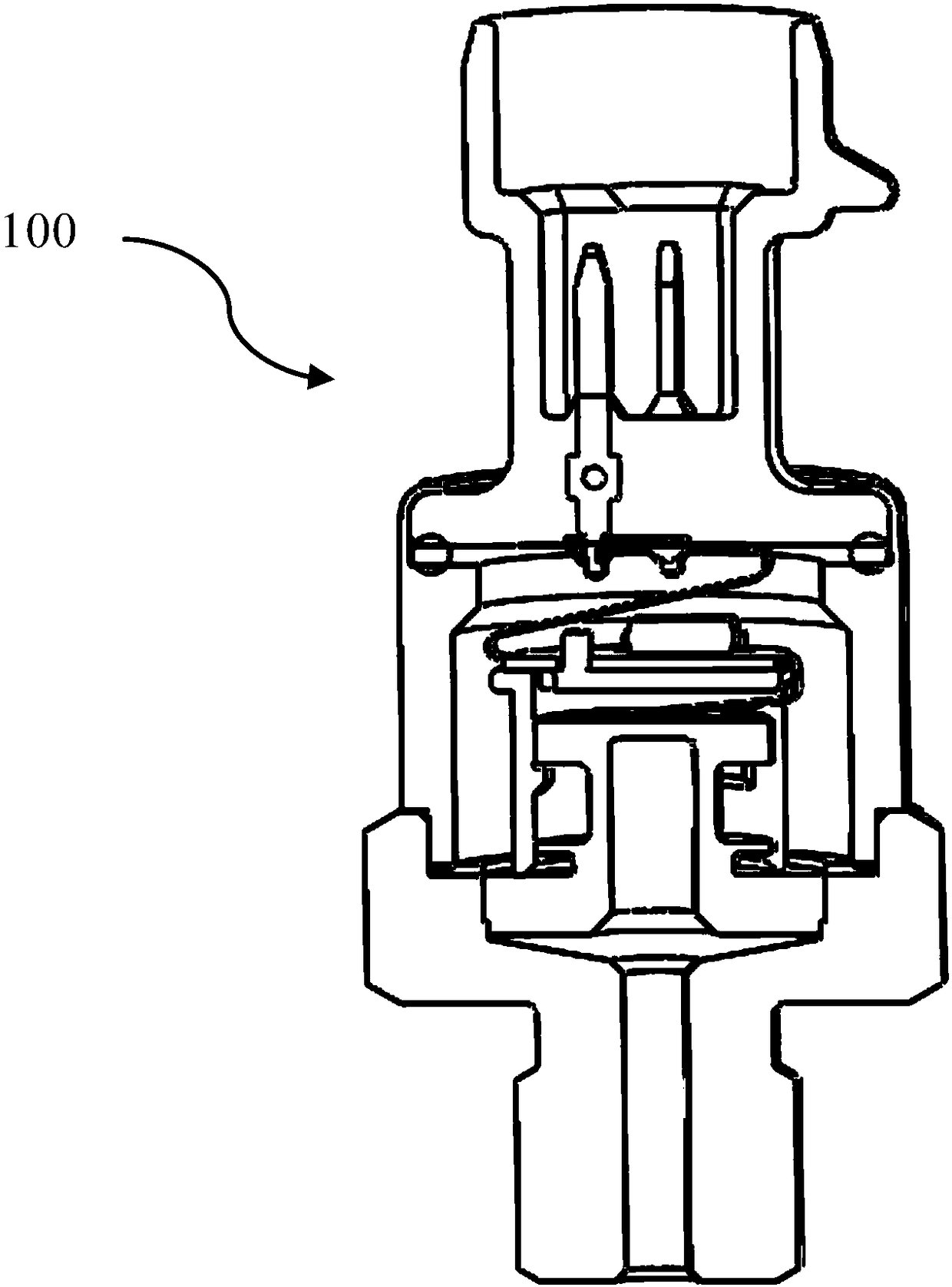

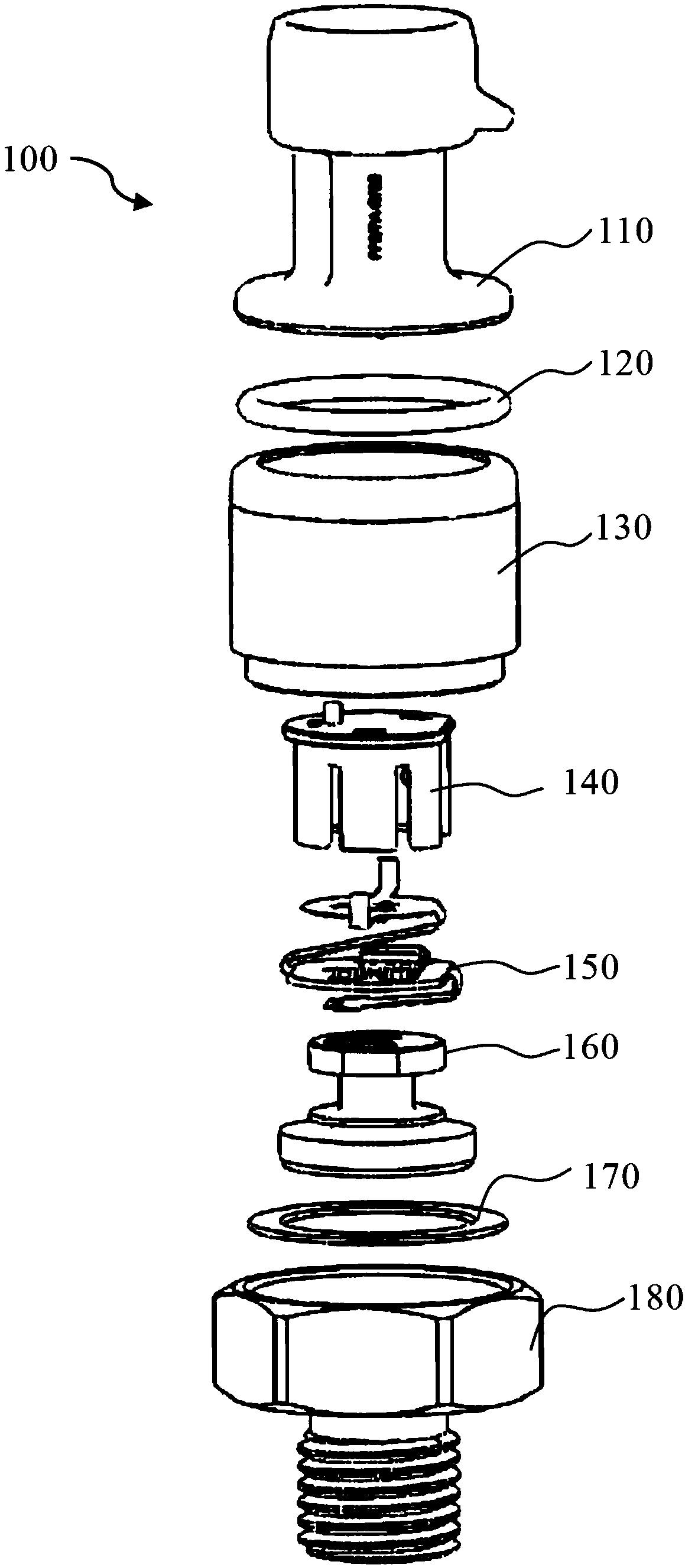

[0032] like Figure 1-2 As shown, a heavy-duty pressure sensor 100 includes a metal casing 130 , a support 140 , a piezoelectric conversion unit 160 , a pressure interface 180 and a signal processing circuit 150 .

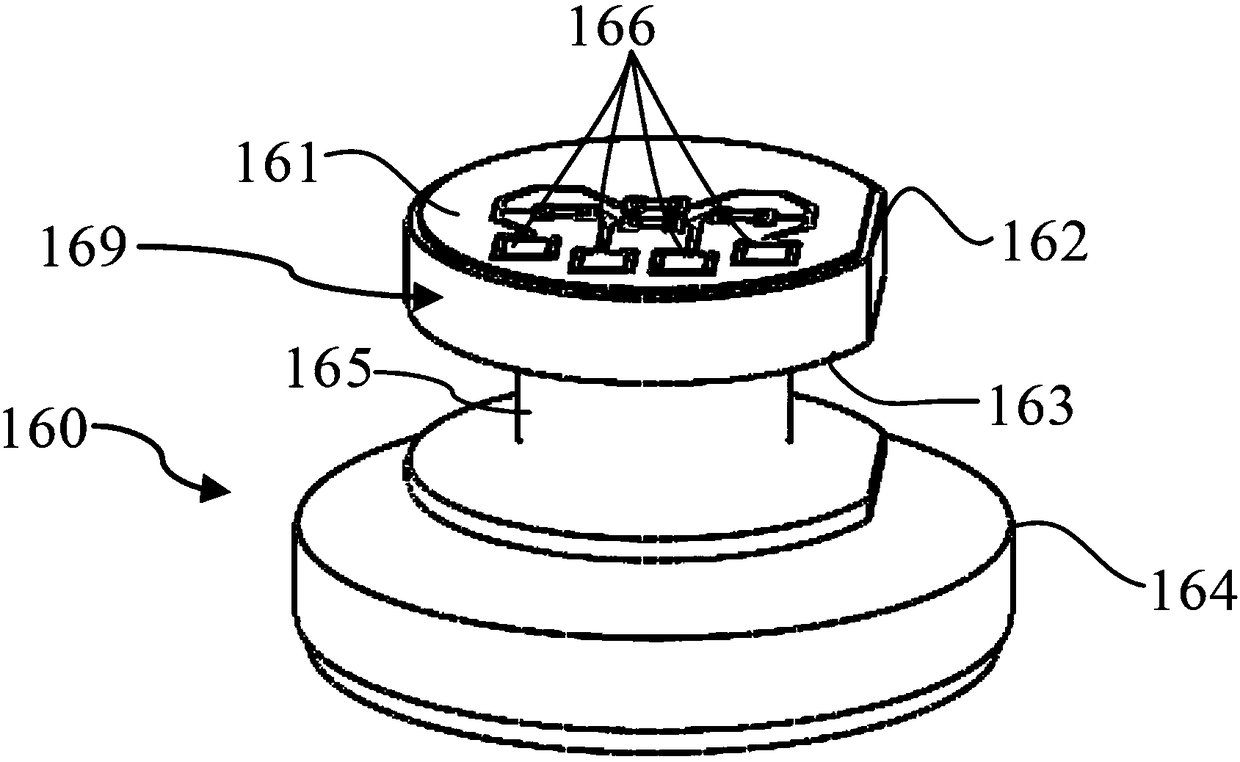

[0033] like image 3 As shown, the piezoelectric conversion unit 160 is composed of a metal substrate 169 and a pressure sensing element 161 arranged on a plane on the metal substrate 169. and femtosecond laser curing to form a dense and firm combination with the metal substrate 169 . Further, a matching cylinder 164 is provided at the bottom of the piezoelectric conversion unit 160, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com