Cannon wiping machine

A gun cleaning machine and reel technology, which is applied in the direction of weapon accessories, offensive equipment, weapon cleaning devices, etc., can solve the problems of poor effect, low requirements for the use of control devices, and harsh use conditions, so as to improve cleaning efficiency and shorten cleaning time. Time, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

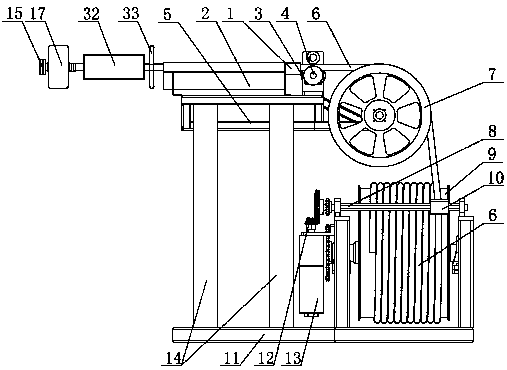

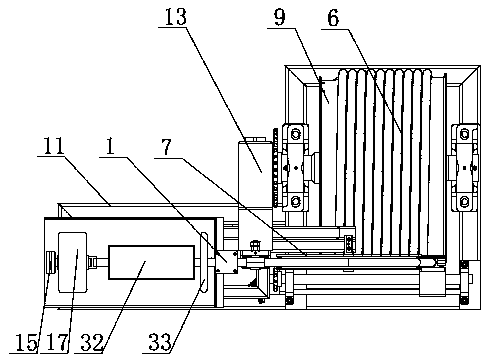

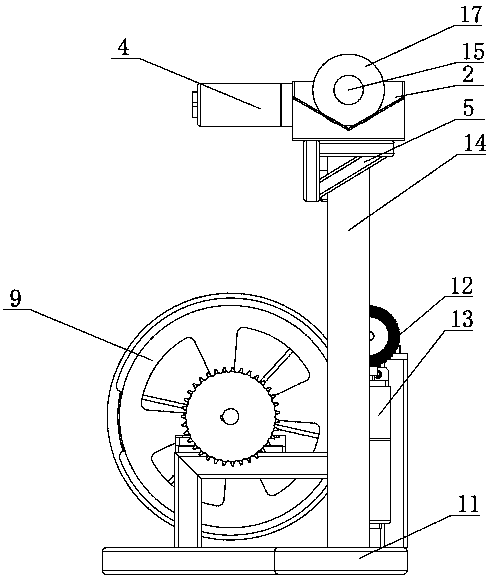

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0028] Such as figure 1 , figure 2 As shown, the pipeline cleaning and conveying device is arranged on the floor support 11, and the reel mechanism is arranged on the floor support 11. The reel mechanism is driven by the reel motor 13 provided at the end, and the reel motor 13 is connected to the right-angle bevel gear 12, and the right-angle umbrella The gear 12 realizes transmission and deceleration, and the right-angle bevel gear 12 can also be a herringbone gear, a helical bevel gear, a curved bevel gear or a hypoid gear. The right-angle bevel gear 12 is connected to the screw mandrel 8, the screw mandrel 8 is parallel to the axis of the reel 9, the slide block 10 and the tube rower are arranged on the screw mandrel 8, and the tube rower is used to arrange the air pipe 6 wound on the reel 9, the air pipe 6 ends are connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com