Efficient casing pipe type air heater device

An air heater and casing type technology, which is applied in the field of high-efficiency casing type air heater devices, can solve problems such as blockage and leakage of power station boiler air heaters, improve heat transfer effect, reduce wind side resistance, and facilitate cleaning The effect of air heater blocking dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

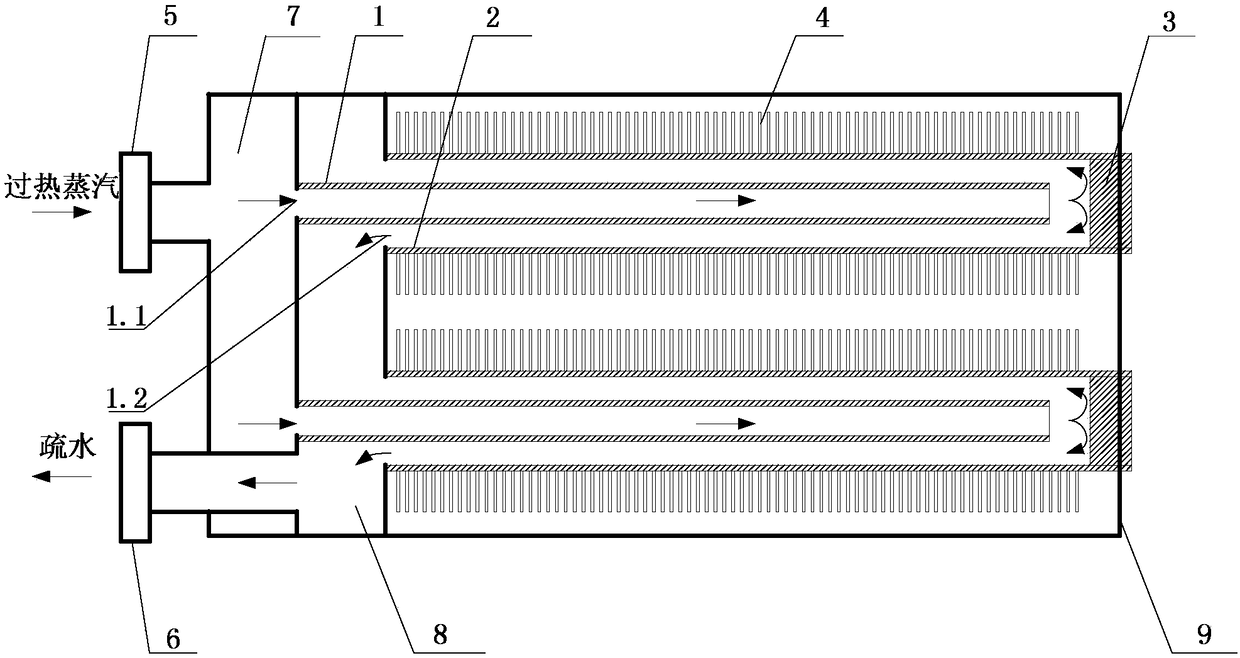

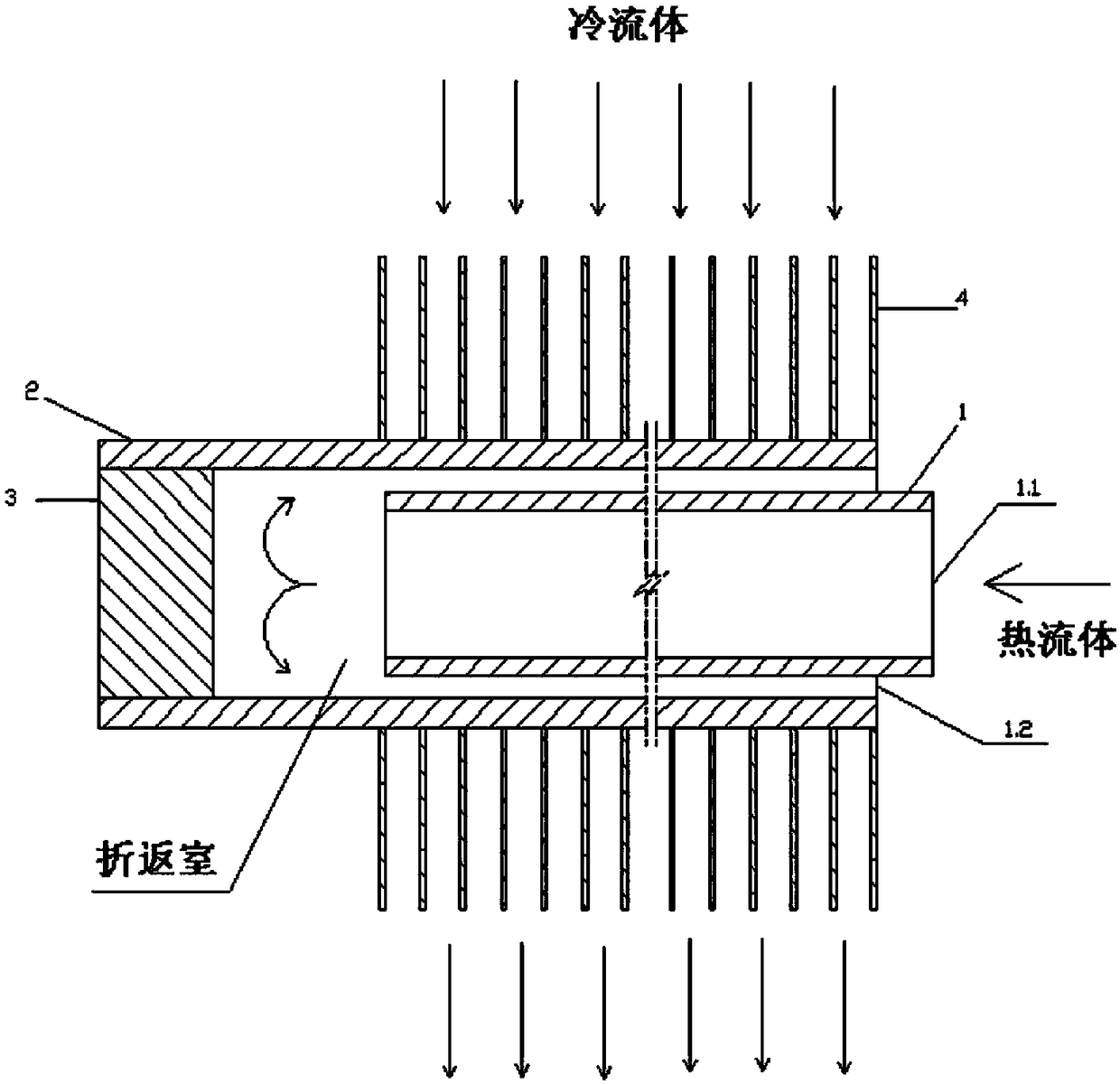

[0025] The heating fluid is extracted from the steam turbine or the steam header pipe. The steam enters the steam header 7 through the steam inlet pipe 5. The steam header 7 is used for steam expansion, and the steam is evenly distributed to each group of finned tubes through the steam inlet 1.1. The steam flows through the inner tube and changes its flow direction in the turn-back chamber. It fills the entire casing interlayer, exchanges heat with the outside cold air and condenses. The condensed water in each group of finned tubes is collected to the drain header 8 through the drain outlet 1.2, and then passes through the water pipe 6 discharge. Since the heat exchange process not only occurs between the finned tube and the cold air, but also between the inner tube 1 and the heating medium in the sleeve interlayer, the condensed water at the drain outlet 1.2 is heated by the superheated steam in the inner tube 1. The degree of subcooling is very small, so the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com