Submarine pipeline suspended section slinging treatment method and sand bag tool used by same

A technology for submarine pipelines and sand bags, which is applied in the directions of pipeline laying and maintenance, pipes/pipe joints/pipes, mechanical equipment, etc. To achieve the effect of reducing the frequency of sand filling operations, simplifying the operation process and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

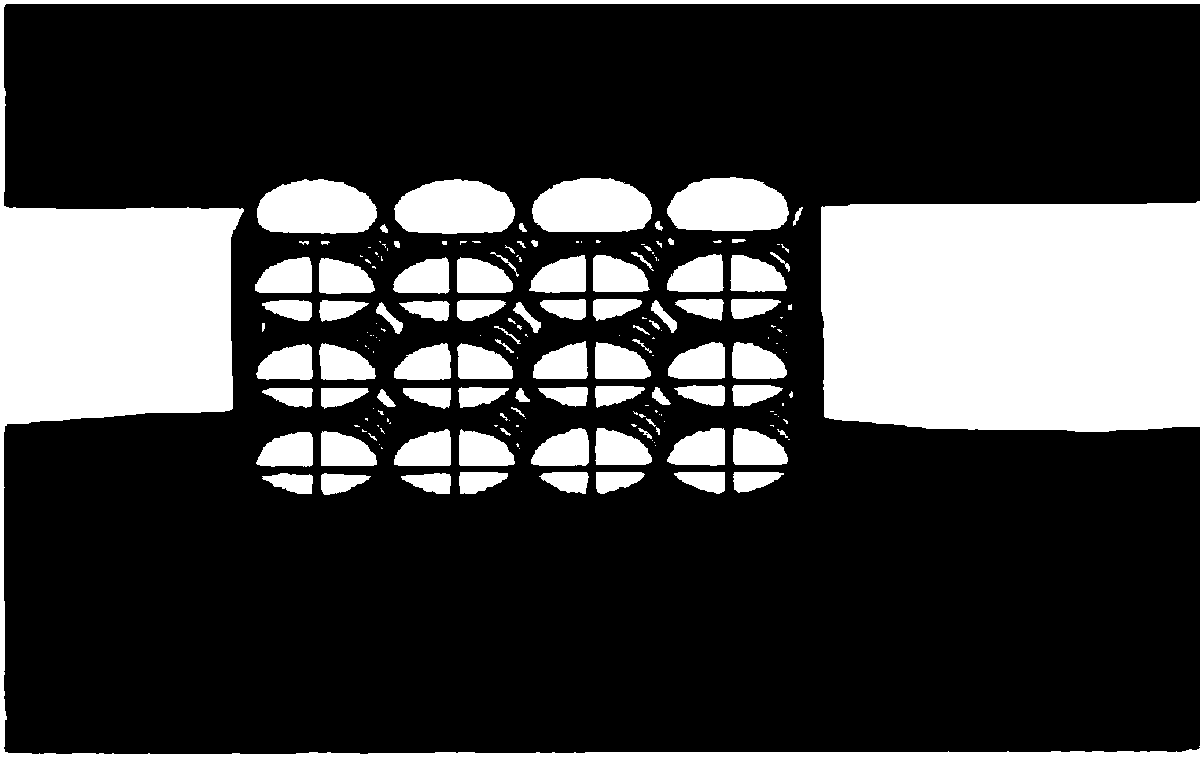

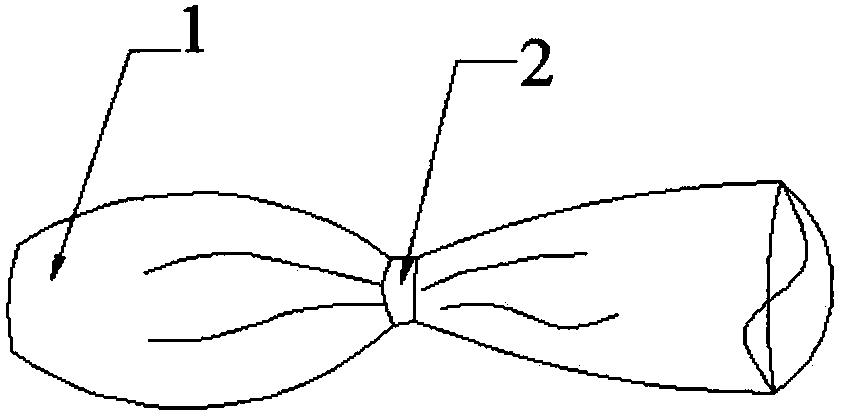

[0045] A sandbag tool used for sandblasting treatment of suspended sections of submarine pipelines, see image 3 , including sand bag 1 and belt 2 that sand is housed. The sandbag 1 has two parts, which are in the shape of a two-stage "candied haws", and the volumes of the two parts are roughly the same; two parts. see Figure 4 , The sand bag tool includes three sand bags 1, and the three sand bags 2 are connected in series end-to-end through a connecting belt 3. Both the strap 2 and the connecting strap 3 are nylon ropes.

[0046] A sand blasting treatment method for suspended sections of submarine pipelines, comprising:

[0047] (1) Put all the sand into the sand bag, seal the sand bag, pinch the middle part of the sand bag with your hands, and tie it with a nylon rope, so that the sand bag is divided into two parts with roughly the same volume;

[0048] (2) Utilize nylon rope to connect 3 above-mentioned sandbags end-to-end in series along the length direction of sand...

Embodiment 2

[0051] A sandbag tool used for sandblasting treatment of suspended sections of submarine pipelines, see Figure 5 , consisting of sandbags and belts filled with sand. The sandbag has three parts, which are in the shape of a three-stage "sugar gourd", and the volumes of the three parts are roughly the same, which are about 1 / 3 of the volume of the entire sandbag; the straps are tied outside the sandbag , so that three parts of the sandbag are formed. The sandbag tool includes one of said sandbags. The belt is as Figure 6 Nylon straps shown.

[0052] A sand blasting treatment method for suspended sections of submarine pipelines, comprising:

[0053] (1) Fill the sand bag with sand. When the sand is filled to about 1 / 3 volume, use nylon binding tape for the first binding; continue to fill sand with about 1 / 3 volume, and use nylon binding tape for the second binding; continue After filling all the sand, seal the sand bag;

[0054] (2) Fill the above-mentioned sandbags below t...

Embodiment 3

[0057] The utility model relates to a sand bag tool used for sand blasting treatment of a suspended section of a submarine pipeline, comprising a sand bag and a belt filled with sand. The sand bag has three parts, which are in the shape of a three-stage "sugar gourd", and the volumes of the three parts are not exactly the same, being about 1 / 4, about 1 / 2 and about 1 / 4 of the volume of the entire sand bag; The straps are strapped over the sandbag such that three parts of the sandbag are formed. The sand bag tool includes two sand bags, and the two sand bags are connected in parallel along the width direction of the sand bag through a connecting belt. The strap is a nylon binding strap, and the connecting strap is a stainless steel wire.

[0058] A sand blasting treatment method for suspended sections of submarine pipelines, comprising:

[0059] (1) Fill the sand bag with sand. When the sand is filled to about 1 / 4 volume, use nylon binding tape for the first binding; continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com