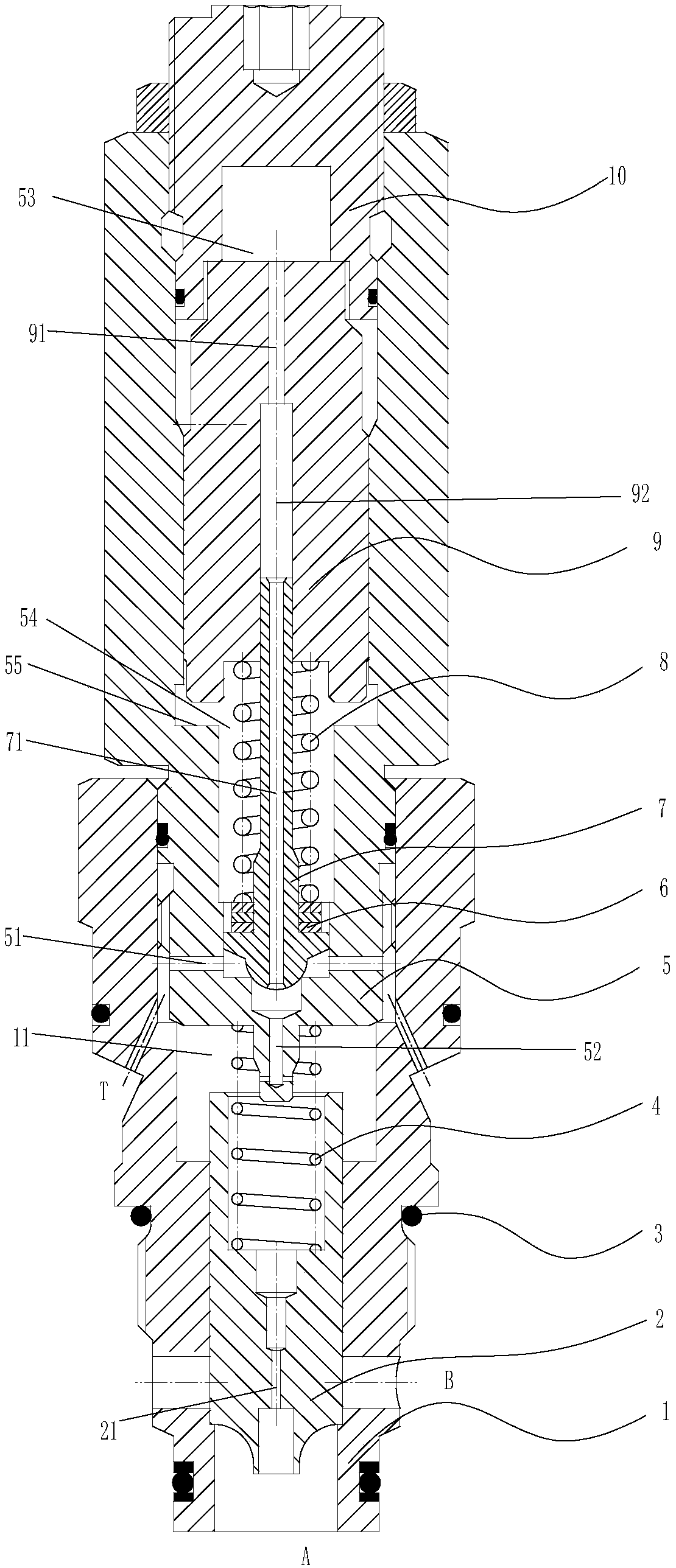

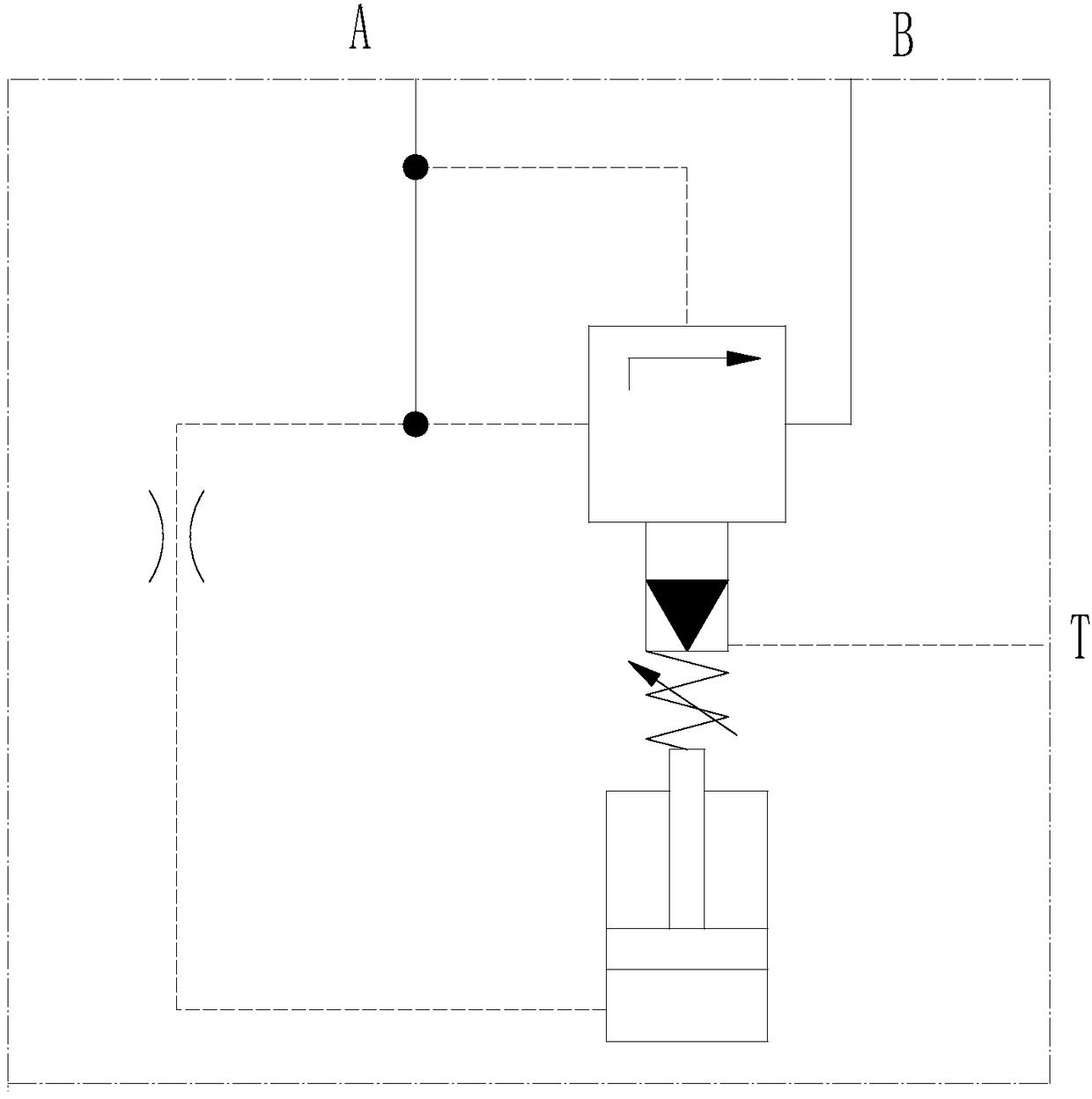

Plug-in type buffer valve

A buffer valve, cartridge technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of small flow capacity, high processing and assembly requirements, severe heat generation, etc., to meet the working conditions of large flow , The effect of effectively buffering the impact pressure, convenient processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, and are not exhaustive of all the embodiments. And in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

[0023] The inventor noticed during the invention process that the existing direct-acting buffer overflow valve has a small flow capacity and is not suitable for a rotary device with a large flow rate. In addition, the existing buffer valve has a complex structure, high processing and assembly requirements, and a relatively high failure rate.

[0024] In view of the above disadvantages, an embodiment of the present invention proposes a plug-in buffer valve, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com