Modified asphalt composition with excellent low-temperature performance and preparation method of modified asphalt composition

A technology of modified asphalt and low-temperature performance, which is applied in building structure, building insulation materials, building components, etc. It can solve problems such as failure to meet requirements and product low-temperature performance constraints, and achieve excellent low-temperature performance, low-temperature ductility improvement, The effect of high ductility at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

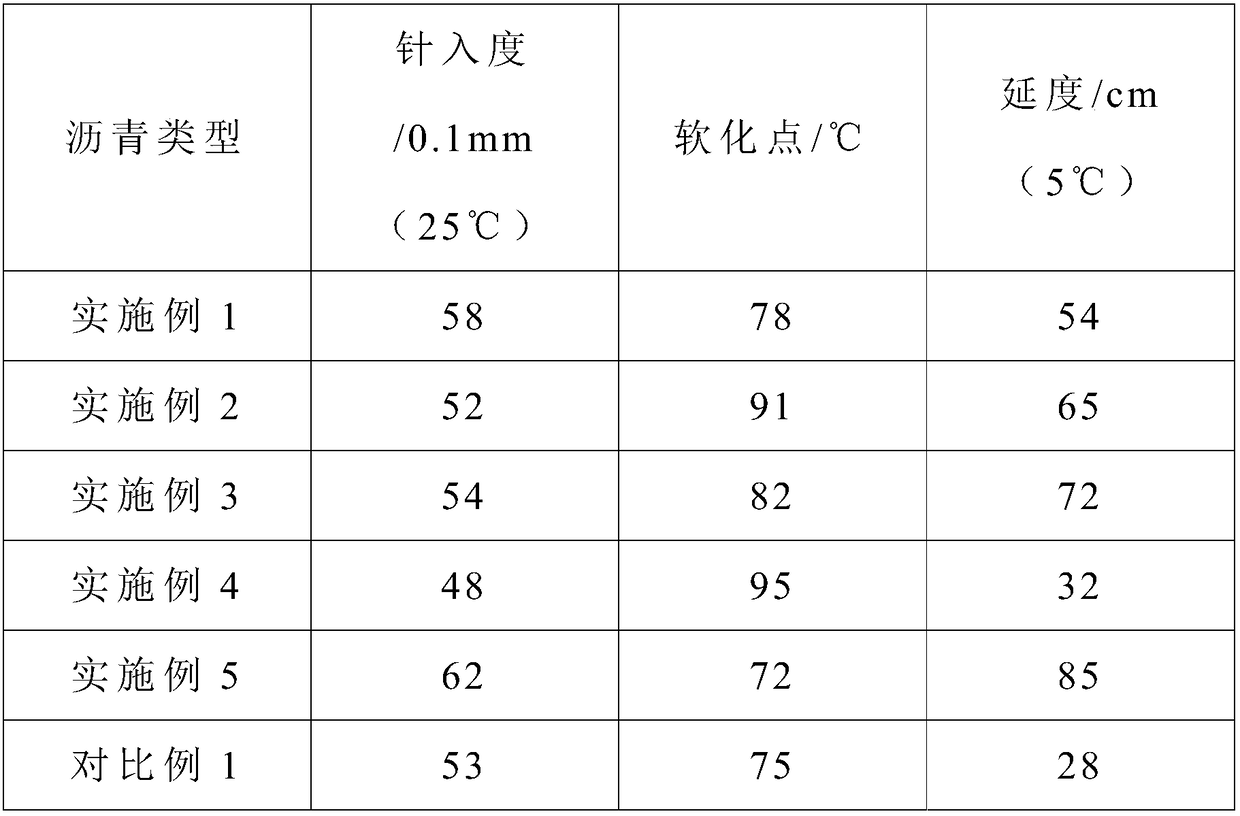

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the above-mentioned modified asphalt composition with excellent low-temperature performance, and the preparation method comprises the steps of:

[0029] S1. Heat the base asphalt to 140°C-160°C, add styrene-butadiene-styrene block copolymer resin, styrene-butadiene rubber, and C9 petroleum resin in parts by mass, cut at a low speed for 30min-40min, The speed is 200r / min~500r / min;

[0030] S2. Heating the temperature to 170°C-180°C, adding aromatic oil, plasticizer, polyethylene wax, and phosphoric acid ester in parts by mass, high-speed shearing for 30min-40min, and shearing speed of 5000r / min-8000r / min;

[0031]S3. Add sulfur and antioxidants in parts by mass, shear at a medium speed for 30 minutes to 40 minutes, and the shear speed is 2000r / min to 4000r / min;

[0032] S4. Control the temperature at 150° C. to 160° C., develop through low speed shearing for 1 h to 2 h, and the shearing speed is 200 r / min to 50...

Embodiment 1

[0036] The modified asphalt composition with excellent low-temperature performance in this embodiment includes the following raw material components in parts by mass: 100 parts of base asphalt, 3 parts of SBS, 1 part of SBR, 1 part of aromatic oil, 1 part of plasticizer, 0.8 part of C9 Petroleum resin, 0.5 part of polyethylene wax, 0.2 part of sulfur, 0.2 part of antioxidant, 0.5 part of phosphate ester.

[0037] Heat the base asphalt of the above-mentioned parts to 160°C, add SBS, SBR, C9 petroleum resin and shear at low speed for 30 minutes; heat the temperature to 170°C, add aromatic oil, plasticizer, polyethylene wax, phosphate ester, and shear at high speed 30min, the shear speed is 6000r / min; add sulfur and antioxidant, medium speed shear 30min, the shear speed is 2000r / min; control the temperature at 155℃, low speed shear development 1.5h, the shear speed is 300r / min, complete the development of modified asphalt, and obtain a modified asphalt composition with excellent...

Embodiment 2

[0039] The modified asphalt composition with excellent low-temperature performance in this embodiment includes the following raw material components in parts by mass: 100 parts of base asphalt, 4 parts of SBS, 1.5 parts of SBR, 1.5 parts of aromatic oil, 2 parts of plasticizer, and 1 part of C9 Petroleum resin, 1 part polyethylene wax, 0.3 part sulfur, 0.3 part antioxidant, 1 part phosphate ester.

[0040] Heat the base asphalt of the above-mentioned parts to 160°C, add SBS, SBR, C9 petroleum resin and shear at low speed for 35 minutes; heat the temperature to 180°C, add aromatic oil, plasticizer, polyethylene wax, phosphate ester, and shear at high speed 40min, with a shear rate of 8000r / min; adding sulfur and antioxidants, shearing at a medium speed for 30min, with a shear rate of 4000r / min; controlling the temperature at 160°C, and developing at a low speed for 2 hours, with a shear rate of 300r / min min, the development of modified asphalt is completed, and a modified aspha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com