Method for preparing grouting material

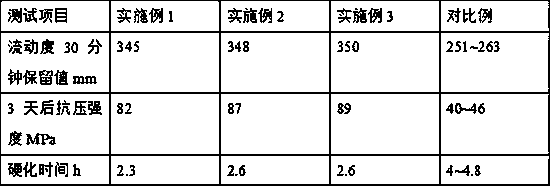

A technology of grouting material and mass ratio, applied in the field of building materials, can solve the problems of poor fluidity and long hardening cycle, and achieve the effect of improving grouting effect, reducing curing time and increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of a grouting material, the preparation method comprising the steps of:

[0025] (1) Mix calcium carbide slag with water evenly at a mass ratio of 1:3, let it stand for 30 minutes, remove the floating matter, then adjust the pH to 5.0~5.5, perform ultrasonic oscillation, filter, collect the filter residue, and press the filter residue and fly ash The mass ratio is 1:3~5, put it into an electric melting furnace for melting, the melting condition is under the atmosphere of carbon dioxide, the melting temperature is 1900~2100°C, melting for 1~2h, and collecting the molten mixture;

[0026] (2) Put the molten mixture and additives into a ball mill at a mass ratio of 6:1~2 for ball milling at 1100r / min for 50 minutes, collect the ball mill, mix the ball mill with water at a mass ratio of 1:3, and place at -30~ Carry out at -20°C for 7~9h, pulverize, pass through a 200-mesh sieve, and collect the sieved particles;

[0027] (3) According to parts by weigh...

Embodiment 1

[0030] The additive is prepared by mixing vermiculite and boehmite at a mass ratio of 2:1.

[0031] The choice of water reducer is polycarboxylate high-performance water reducer (purchase: Shandong Huawei Yinkai Building Materials Technology Co., Ltd.).

[0032] The auxiliary agent is benzoin ether.

[0033] The anti-cracking agent is SY-G high-performance expansion anti-cracking agent (purchase: Zhongxing New Building Materials Co., Ltd.).

[0034] A preparation method of a grouting material, the preparation method comprising the steps of:

[0035] (1) Mix calcium carbide slag with water evenly at a mass ratio of 1:3, let it stand for 30 minutes, remove the floating matter, then adjust the pH to 5.5, perform ultrasonic oscillation, filter, collect the filter residue, and mix the filter residue and fly ash according to the mass ratio 1:4, put it into an electric melting furnace for melting, the melting condition is under the atmosphere of carbon dioxide, the melting temperat...

Embodiment 2

[0040] The additive is prepared by mixing vermiculite and boehmite at a mass ratio of 2:1.

[0041] The choice of water reducer is HSB aliphatic high-efficiency water reducer (purchase: Qingdao Hongxia Polymer Material Co., Ltd.).

[0042] The auxiliary agent is Michler's ketone.

[0043] The anti-cracking agent is SY-G high-performance expansion anti-cracking agent (purchase: Zhongxing New Building Materials Co., Ltd.).

[0044] A preparation method of a grouting material, the preparation method comprising the steps of:

[0045] (1) Mix calcium carbide slag with water evenly at a mass ratio of 1:3, let it stand for 30 minutes, remove the floating matter, then adjust the pH to 5.5, perform ultrasonic oscillation, filter, collect the filter residue, and mix the filter residue and fly ash according to the mass ratio 1:5, put it into an electric melting furnace for melting, the melting condition is under an atmosphere of carbon dioxide, the melting temperature is 2100 ° C, melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com