Automobile axle housing

A technology for axle housings and automobiles, which is applied to axles, wheels, and vehicle parts. It can solve problems such as low material utilization, low fatigue life at welds, and high welding quality requirements, so as to increase integrity and structural strength, and eliminate welding. Defects, the effect of optimizing the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be described in further detail below in conjunction with the accompanying drawings.

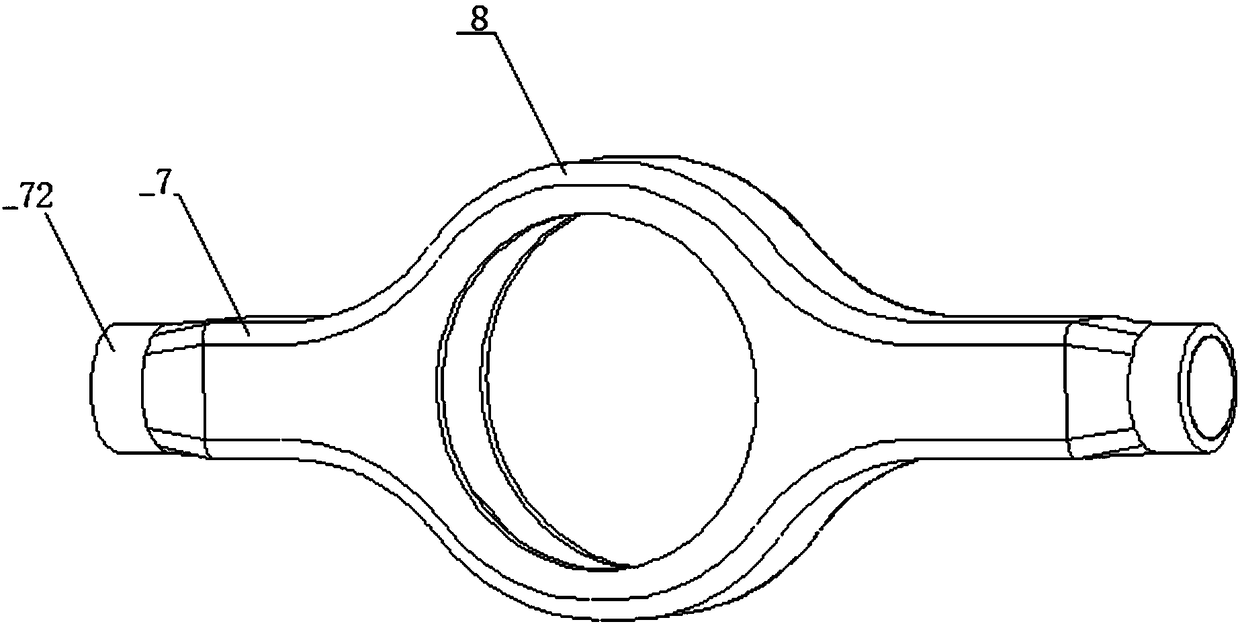

[0077] An automobile axle housing, the automobile axle housing is a hollow shell, the upper and lower bottom surfaces of the automobile axle housing are a pair of parallel end surfaces, and the axle housing body includes a bridge that expands into a circle through a mold along the width direction. The middle part of the axle housing and the ends of the axle housing symmetrically distributed on both sides of the middle part of the axle housing, the upper and lower bottom surfaces of the middle part of the axle housing are respectively provided with circular through holes 71 .

[0078] Further, a circular end 72 is formed on the end stop of the end of the axle housing.

[0079] Further, made by the following steps:

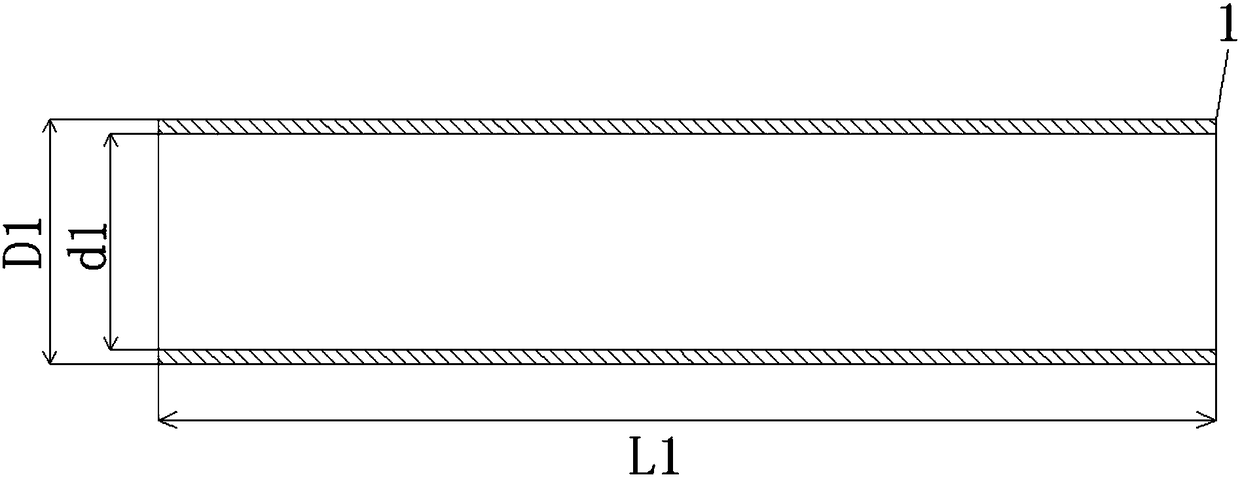

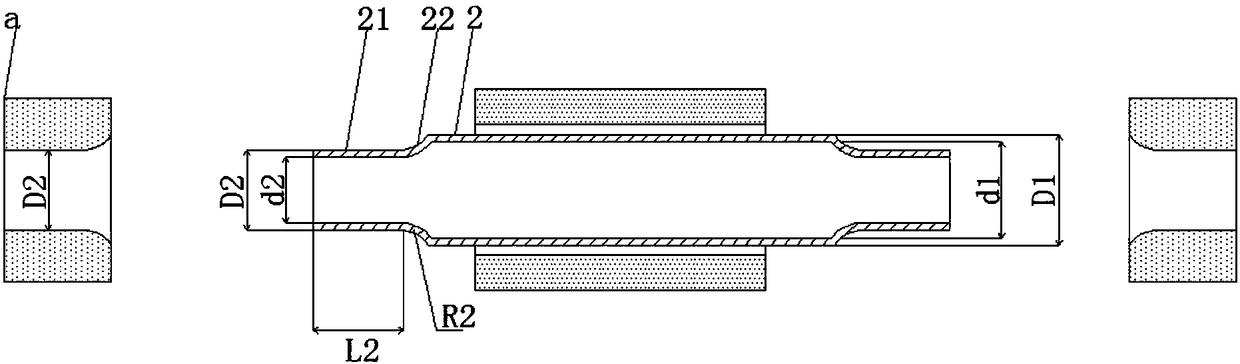

[0080] Step 1, cutting the tubing:

[0081] Cutting the circular steel pipe into a first intermediate product 1 with an outer diameter D1, an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com