Device for preparing double-shell microcapsules

A double-layer shell and microcapsule technology, which is applied in the field of food machinery, can solve the problems of low repeatability of experiments, industrial production, uneven size of double-layer microcapsules, and complicated preparation process, and achieve shortened production time, easy control, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

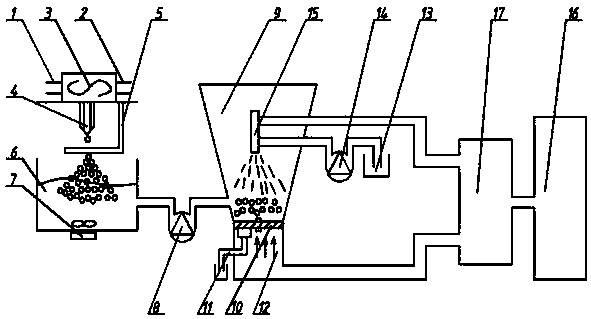

[0013] A device for preparing double-layer shell microcapsules described in this embodiment includes a core material liquid inlet 1, a wall material liquid inlet 2, a vibration system 3, a concentric nozzle 4, an electrode 5, a collector 6, an agitator 7, Peristaltic pump Ⅰ8, second coating chamber 9, rotatable screen 10, water outlet 11, air inlet 12, coating liquid inlet 13, peristaltic pump Ⅱ14, atomizing nozzle 15, air compressor 16, temperature control system 17.

[0014] The core material liquid inlet 1 is located on the left side above the first layer coating machine, the wall material liquid inlet 2 is located on the right side above the first layer coating machine, the core material liquid inlet and the wall material liquid inlet are connected to the vibration system at the same time 3. The vibration system 3 is connected to the concentric nozzle 4, the electrode 5 is located below the nozzle 4, the collector 6 is located directly below the first layer coating machine...

Embodiment 2

[0017] Take 0.5% 500ml sodium alginate solution and 0.5% 100ml proanthocyanidin solution from the liquid inlets 1 and 2 respectively, and through the indirect extrusion of the vibration system 3, the concentric nozzle 4 produces uniform single-core single-wall water. The condensation beads are dispersed into the hardening solution containing 1% calcium chloride after passing through the electrode 5. The water condensation beads are hardened by the hardening solution in the collector 6, and then enter the lower part of the second coating chamber 9 through the peristaltic pump I8, and the hardening solution It is discharged through the drain outlet on the left side of the rotatable screen 10, and the particles trapped on the screen are blown up by the hot air at the air inlet 12 to realize fluidization. Delivered to the atomizing nozzle 15 at the top of 9, after atomization, meets the fluidized particles to form a second layer of coating. Thereby producing double-layer proanthoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com