Preparation method of stable-hygroscopicity tissue adhesive material

An adhesive and stable technology, which is applied in the field of preparation of hygroscopic stable tissue adhesive materials, can solve the problems of poor adhesiveness and ineffective bonding of the adhesive, and achieves improvement in the decrease of adhesive performance and the improvement of hygroscopic stability. Performance, effect of good hygroscopic and moisturizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

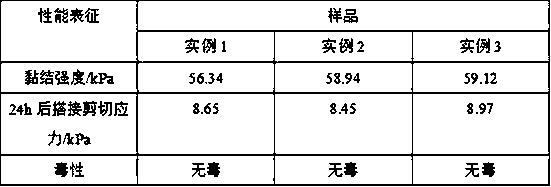

Examples

example 1

[0018] Take the mangosteen fruit, remove the shell and core, and vacuum freeze-dry to a moisture content of 5%, ball mill and grind through a 100-mesh sieve to obtain a dry powder, and add the dry powder to an 85% ethanol solution in a mass ratio of 1:10 in water bath at 65-75°C for 2-3 hours, let it cool down to room temperature and filter to obtain a filter cake. According to the mass ratio of 1:10, stir and mix the filter cake with deionized water and place it under 250-300W Ultrasonic-assisted extraction for 3-5 hours, control the extraction temperature at 75-85°C, let it cool down to room temperature and filter to obtain the filtrate, add 5% ethanol dropwise to the filtrate at a volume ratio of 1:5, and let it stand for 6 After ~8h, centrifuge at 1500~2000r / min for 10~15min, collect the lower sediment and vacuum freeze-dry to obtain modified particles. In parts by weight, weigh 45~50 parts of deionized water, 13~ 15 parts of rubber viscose fiber, 10-15 parts of modified p...

example 2

[0020] Take the mangosteen fruit, remove the shell and core, and vacuum freeze-dry to a moisture content of 5%, ball mill and grind through a 100-mesh sieve to obtain a dry powder, and add the dry powder to an 85% ethanol solution in a mass ratio of 1:10 in water bath at 65-75°C for 2-3 hours, let it cool down to room temperature and filter to obtain a filter cake. According to the mass ratio of 1:10, stir and mix the filter cake with deionized water and place it under 250-300W Ultrasonic-assisted extraction for 3-5 hours, control the extraction temperature at 75-85°C, let it cool down to room temperature and filter to obtain the filtrate, add 5% ethanol dropwise to the filtrate at a volume ratio of 1:5, and let it stand for 6 After ~8h, centrifuge at 1500~2000r / min for 10~15min, collect the lower sediment and vacuum freeze-dry to obtain modified particles. In parts by weight, weigh 45~50 parts of deionized water, 13~ 15 parts of rubber viscose fiber, 10-15 parts of modified p...

example 3

[0022] Take the mangosteen fruit, remove the shell and core, and vacuum freeze-dry to a moisture content of 5%, ball mill and grind through a 100-mesh sieve to obtain a dry powder, and add the dry powder to an 85% ethanol solution in a mass ratio of 1:10 in water bath at 65-75°C for 2-3 hours, let it cool down to room temperature and filter to obtain a filter cake. According to the mass ratio of 1:10, stir and mix the filter cake with deionized water and place it under 250-300W Ultrasonic-assisted extraction for 3-5 hours, control the extraction temperature at 75-85°C, let it cool down to room temperature and filter to obtain the filtrate, add 5% ethanol dropwise to the filtrate at a volume ratio of 1:5, and let it stand for 6 After ~8h, centrifuge at 1500~2000r / min for 10~15min, collect the lower sediment and vacuum freeze-dry to obtain modified particles. In parts by weight, weigh 45~50 parts of deionized water, 13~ 15 parts of rubber viscose fiber, 10-15 parts of modified p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com