A kind of graphitized carbon coated electrode material and preparation method thereof and application as electrode material of energy storage device

An electrode material and graphitized carbon technology, which is applied in the field of energy storage, can solve the problems of poor interface connection between carbon materials and electrode materials, low degree of graphitization of carbon materials, uneven coating, etc. Excellent capacity, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

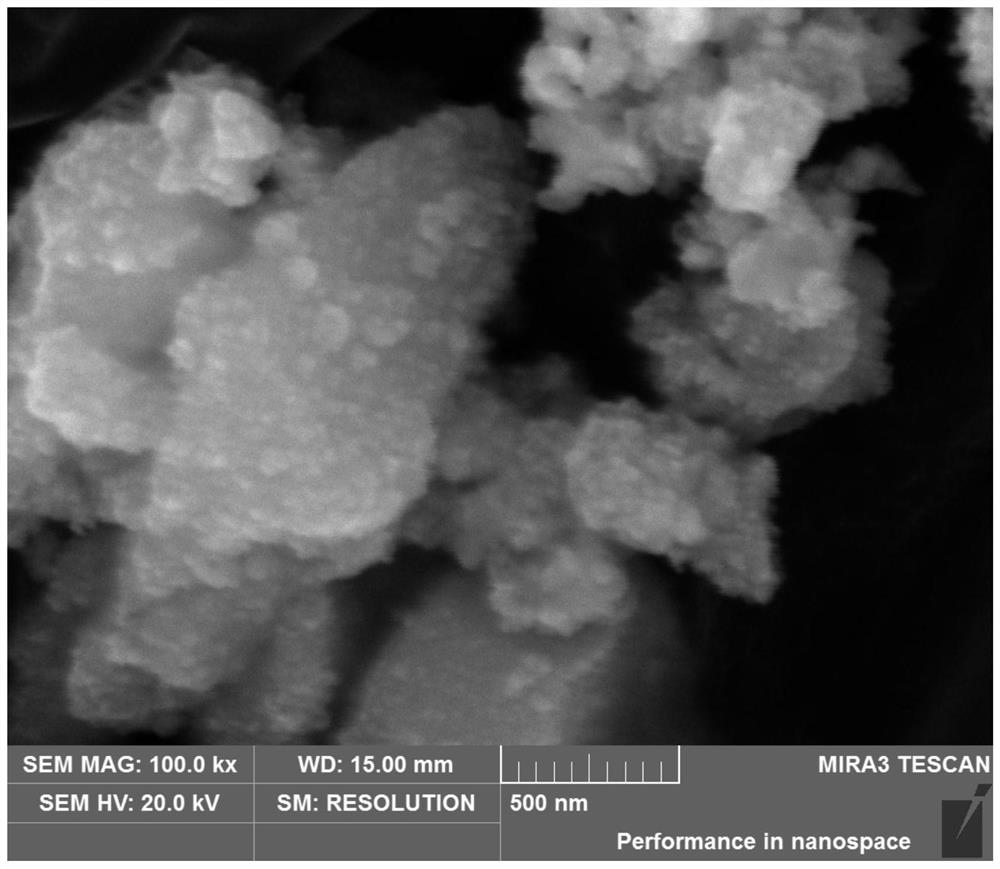

[0039] First, 1.0ml of titanium chloride solution (15% titanium trichloride dilute hydrochloric acid solution) and a certain amount of cetyltrimethylammonium bromide (CTAB; 0.58g) were dissolved and uniformly dispersed in n-hexane (60ml) and In a mixed organic solvent composed of n-pentanol (10ml), then transferred to a 100ml reaction kettle, solvothermal in an oven at 200°C for 6h and directly vacuum-dried to obtain a mixture of organic matter and titanium dioxide precursor. Then, it was calcined at 800°C for 2h in an inert protective gas environment, the heating rate was 10°C / min, and the temperature was naturally lowered. The obtained black powder is a composite of titanium dioxide electrode material coated with graphitized carbon. figure 1 It is the physical photo of the organic matter and titanium dioxide precursor obtained after solvothermal, indicating that the obtained material is a white paste. figure 2 The scanning electron microscope image of the composite of the ...

Embodiment 2

[0046] First, 1.0ml of titanium chloride solution (15% titanium trichloride dilute hydrochloric acid solution) and a certain amount of cetyltrimethylammonium bromide (CTAB; 0.58g) were dissolved and uniformly dispersed in n-hexane (60ml) and In a mixed organic solvent composed of n-pentanol (10ml), then transferred to a 100ml reaction kettle, solvothermal in an oven at 200°C for 6h and directly vacuum-dried to obtain a mixture of organic matter and titanium dioxide precursor. Then, it was calcined at 900°C for 2h in an inert protective gas environment, the heating rate was 10°C / min, and the temperature was naturally lowered. A black powder of titanium dioxide electrode material coated with graphitized carbon was obtained.

[0047] The composite of the obtained graphitized carbon-coated titanium dioxide electrode material is used as the negative electrode material of the sodium ion battery, and is adjusted according to the mass ratio of the active material and the conductive ag...

Embodiment 3

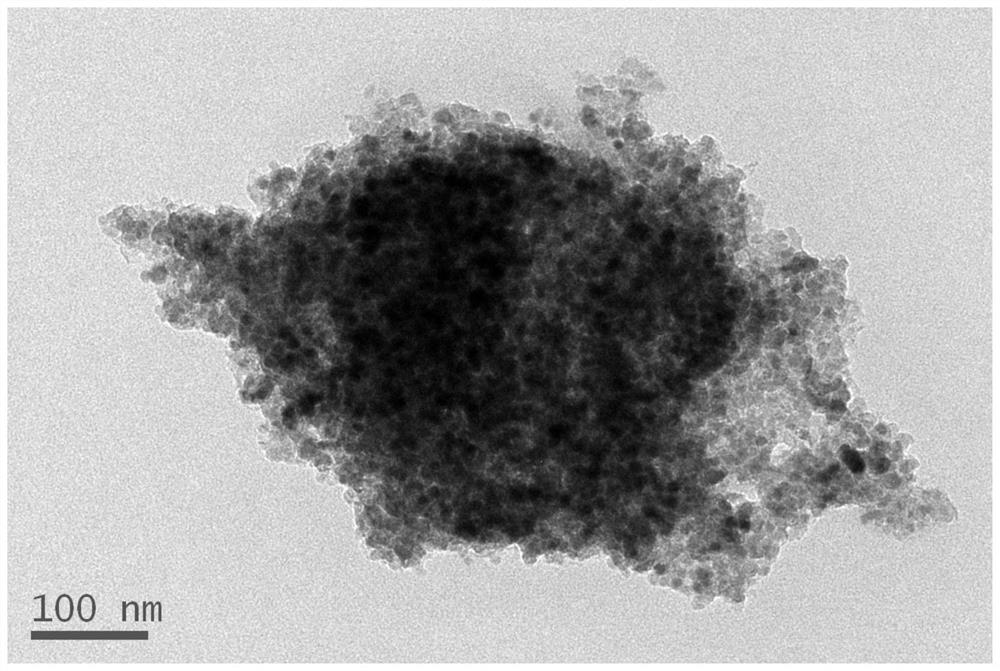

[0049] First, 1.0ml of titanium chloride solution (15% titanium trichloride dilute hydrochloric acid solution) and a certain amount of cetyltrimethylammonium bromide (CTAB; 0.58g) were dissolved and uniformly dispersed in n-hexane (60ml) and in a mixed organic solvent composed of n-hexanol (10ml), then transferred to a 100ml reaction kettle, and solvothermally dried in an oven at 200°C for 6h and directly vacuum-dried to obtain a mixture of organic matter and titanium dioxide precursor. Then, it was calcined at 800°C for 2h in an inert protective gas environment, the heating rate was 10°C / min, and the temperature was naturally lowered. A black powder of titanium dioxide electrode material coated with graphitized carbon was obtained. Figure 8 The transmission electron micrograph of the composite of the prepared graphitized carbon-coated titanium dioxide electrode material shows that the coating layer of titanium dioxide particles is a graphitized carbon structure, but the degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com