Photoresist pattern preparing method

A photoresist pattern and photoresist technology, which is applied in the photoplate making process of the pattern surface, optical mechanical equipment, optics, etc., can solve the problems of expensive photomask, complicated exposure operation, and low precision, so as to save Photomask, improve preparation accuracy, and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

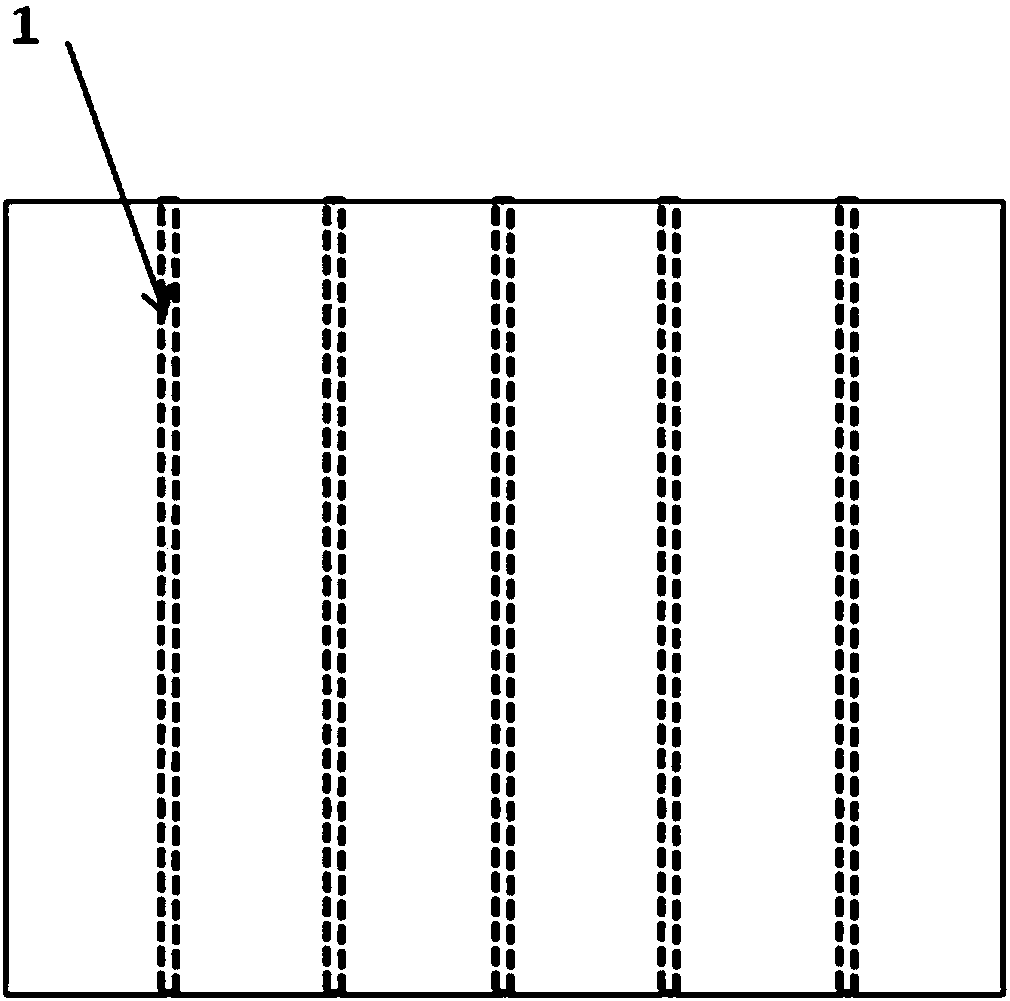

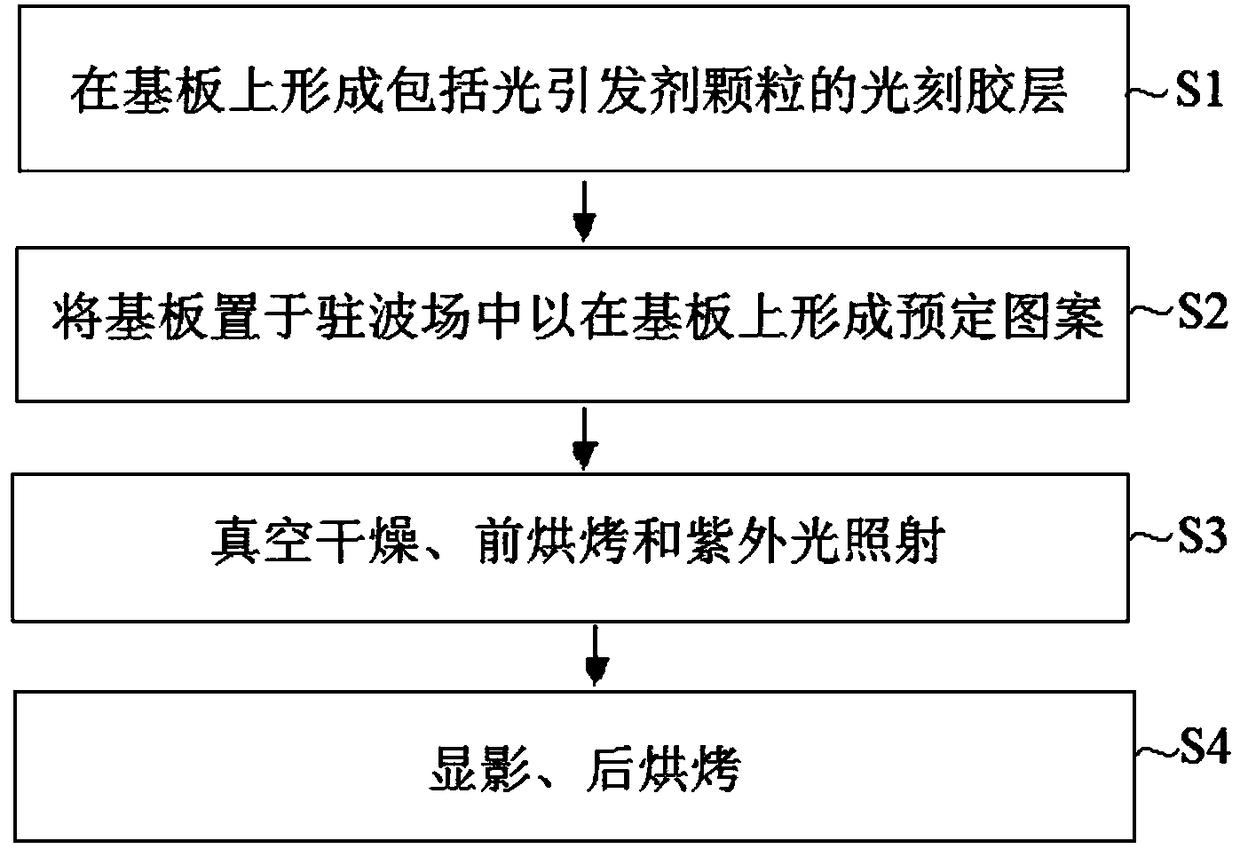

[0028] In the existing method for preparing a photoresist pattern, a photomask is used to form the photoresist pattern during the exposure process, but the photomask is expensive and the exposure operation is complicated. For this reason, the present invention proposes a novel method for preparing a photoresist pattern without using a photomask. According to the present invention, it is proposed to use the standing wave field principle to prepare the photoresist pattern, so that the photomask can be omitted, the manufacturing cost can be saved, and the precision of the photoresist pattern can be improved at the same time. A method of preparing a photoresist pattern according to the present invention will be described in detail below with reference to the accompanying drawings.

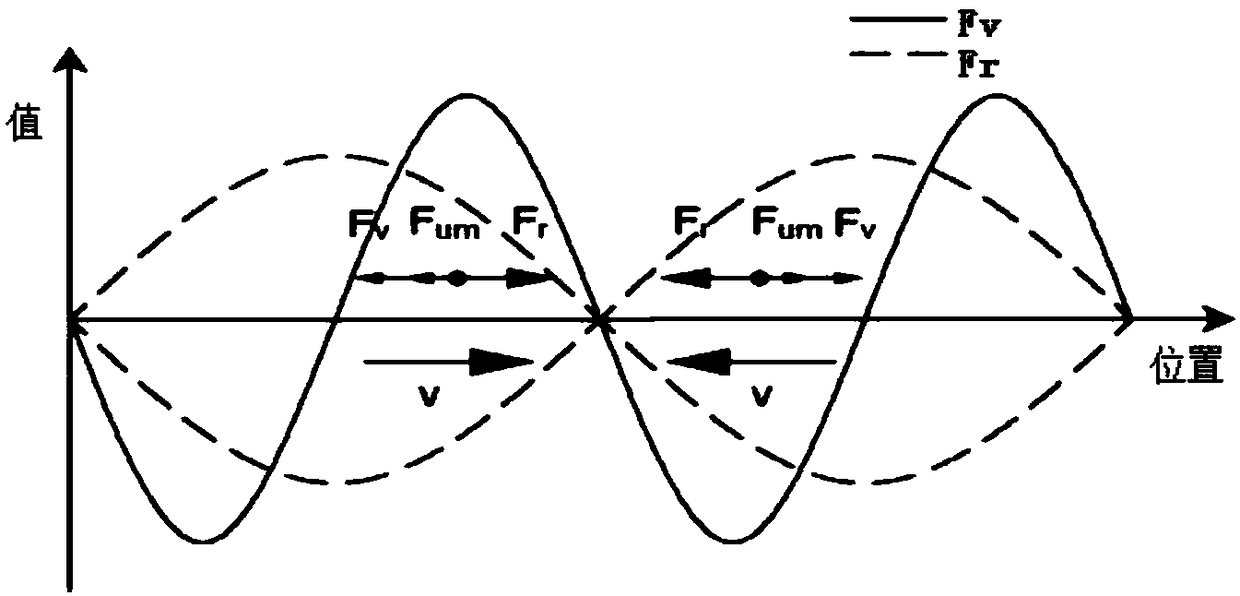

[0029] First, the following will refer to Figure 1A and Figure 1B To explain the principle of the standing wave field on which the method for preparing a photoresist pattern according to the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com