Fluorescent sensor and application thereof in determination of niclosamide

A fluorescent sensor and ink technology, applied in the field of fluorescent sensors, can solve the problems of large error of niclosamide, low sensitivity, environmental pollution, etc., and achieve the effects of high accuracy, improved sensitivity, and less sample consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

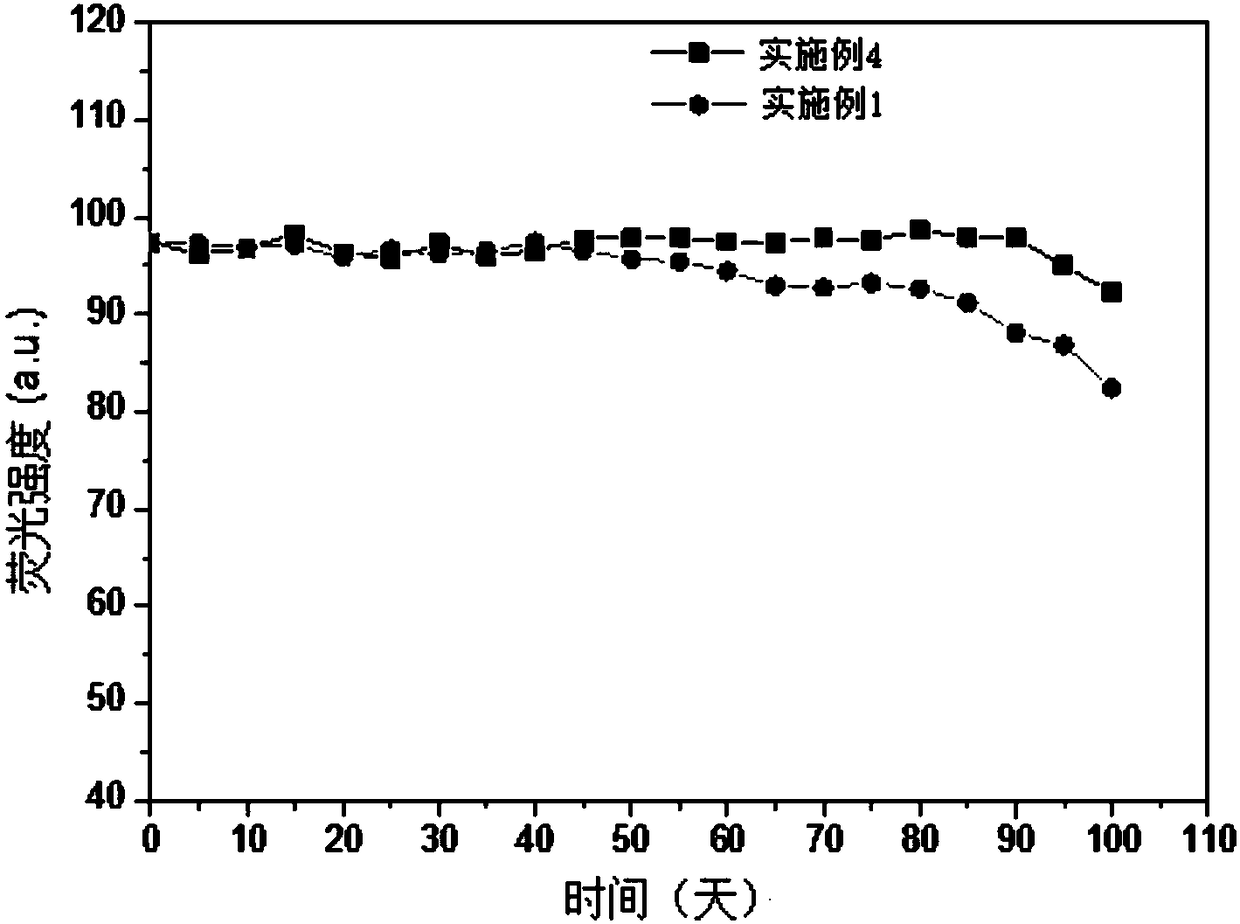

Embodiment 1

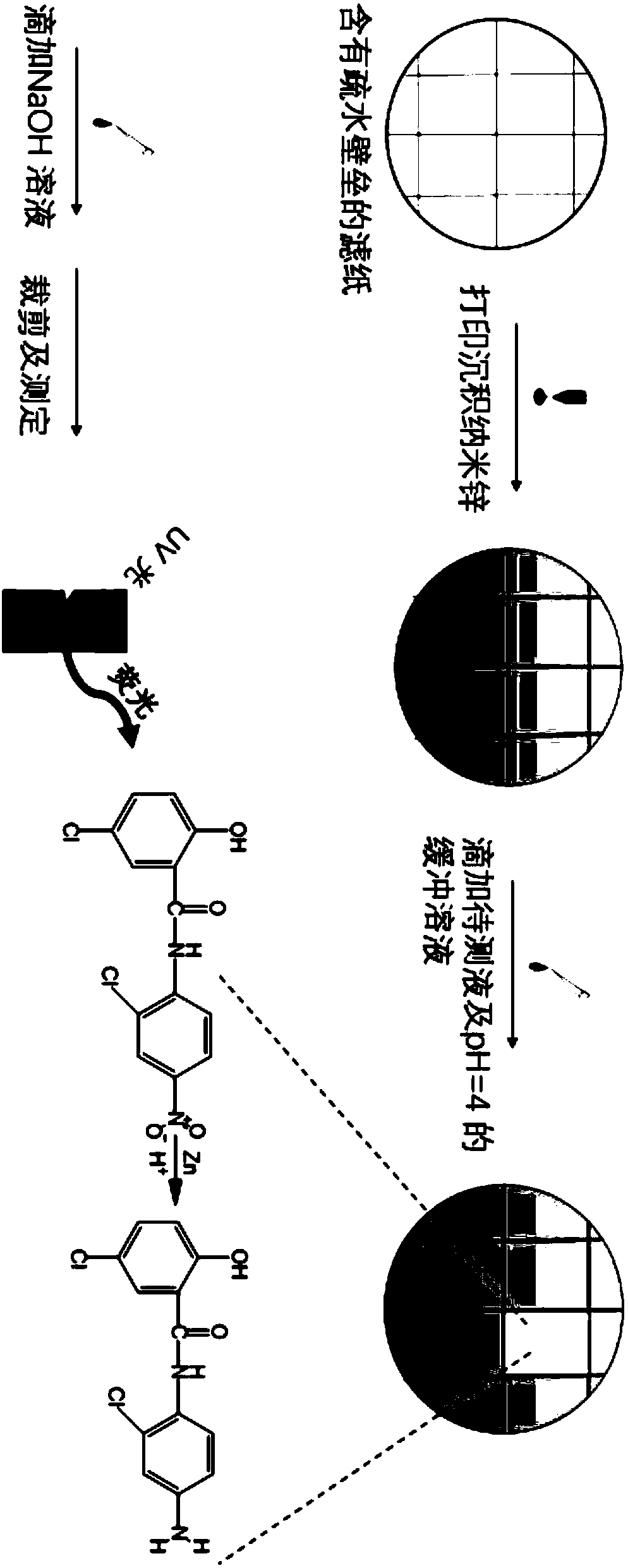

[0052] In the present embodiment, the base material of the fluorescent sensor is filter paper No. whatman#1, and the nano-zinc powder ink is composed of the following components in mass percentage: 5.2% of nano-zinc powder, 29.4% of ethylene glycol, 6% of isopropanol, and 14% of ethanol %, TritonX-100 4.2%, the balance is water. Its viscosity is 2.89mPa·s and its surface tension is 38.97mN / m.

[0053] The preparation method is as follows: add 1mL of the above-mentioned nano-zinc powder ink to a clean ink cartridge, install the ink cartridge in an inkjet printer, and use a paraffin crayon to coat paraffin on the filter paper to form a sample adding area on whatman#1 filter paper (i.e. figure 1 The grid in the middle) was melted and infiltrated at 60°C for 5 minutes, and then the above-mentioned nano-zinc powder ink was printed on filter paper and printed 8 times to prepare a fluorescent sensor.

Embodiment 2

[0055] In the present embodiment, the base material of the fluorescent sensor is filter paper No. whatman#1, and the nano-zinc powder ink is made up of the following components by mass percentage: nano-zinc powder 7.8%, ethylene glycol 24.5%, isopropanol 9.5%, ethanol 10.5% %, TritonX-100 1%, the balance is water. Its viscosity is 2.13mPa·s, and its surface tension is 42.86mN / m.

[0056] The preparation method is the same as in Example 1.

Embodiment 3

[0058] In the present embodiment, the base material of the fluorescent sensor is filter paper No. whatman#1, and the nano-zinc powder ink is made up of the following components in mass percentage: nano-zinc powder 3.4%, ethylene glycol 27.5%, isopropanol 8%, ethanol 13.2% %, TritonX-114 3.6%, the balance is water. Its viscosity is 2.67mPa·s and its surface tension is 39.42mN / m.

[0059] The preparation method is the same as in Example 1.

[0060] 2. Contains polyvinyl alcohol

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com