Rapid mapping method for CVD diamond coating wire drawing die hole pattern

A technology of diamond coating and wire drawing die, which is applied in the direction of measuring device, mechanical measuring device, mechanical counter/curvature measurement, etc., can solve the problems of expensive surveying and mapping equipment and low surveying and mapping accuracy, and achieve low cost, high surveying and mapping accuracy, surveying and mapping high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

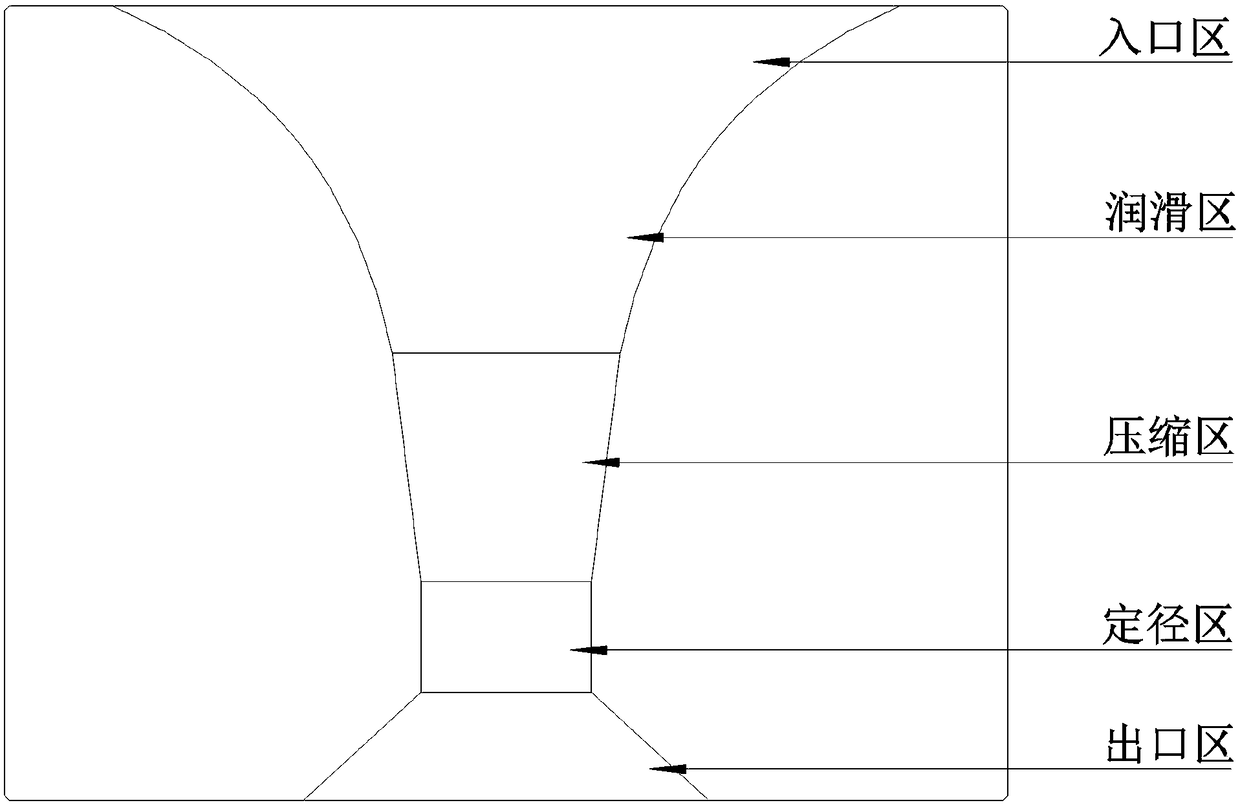

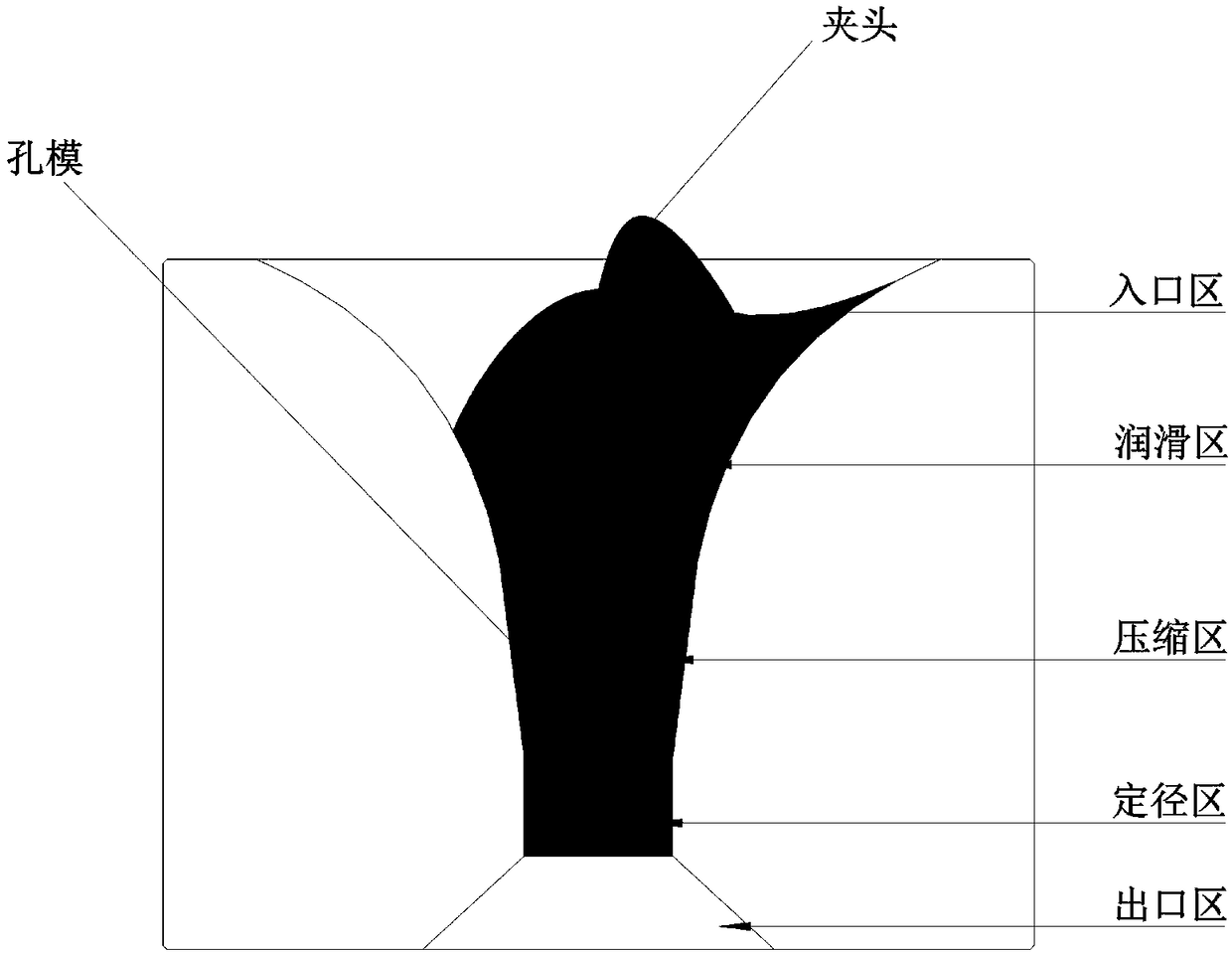

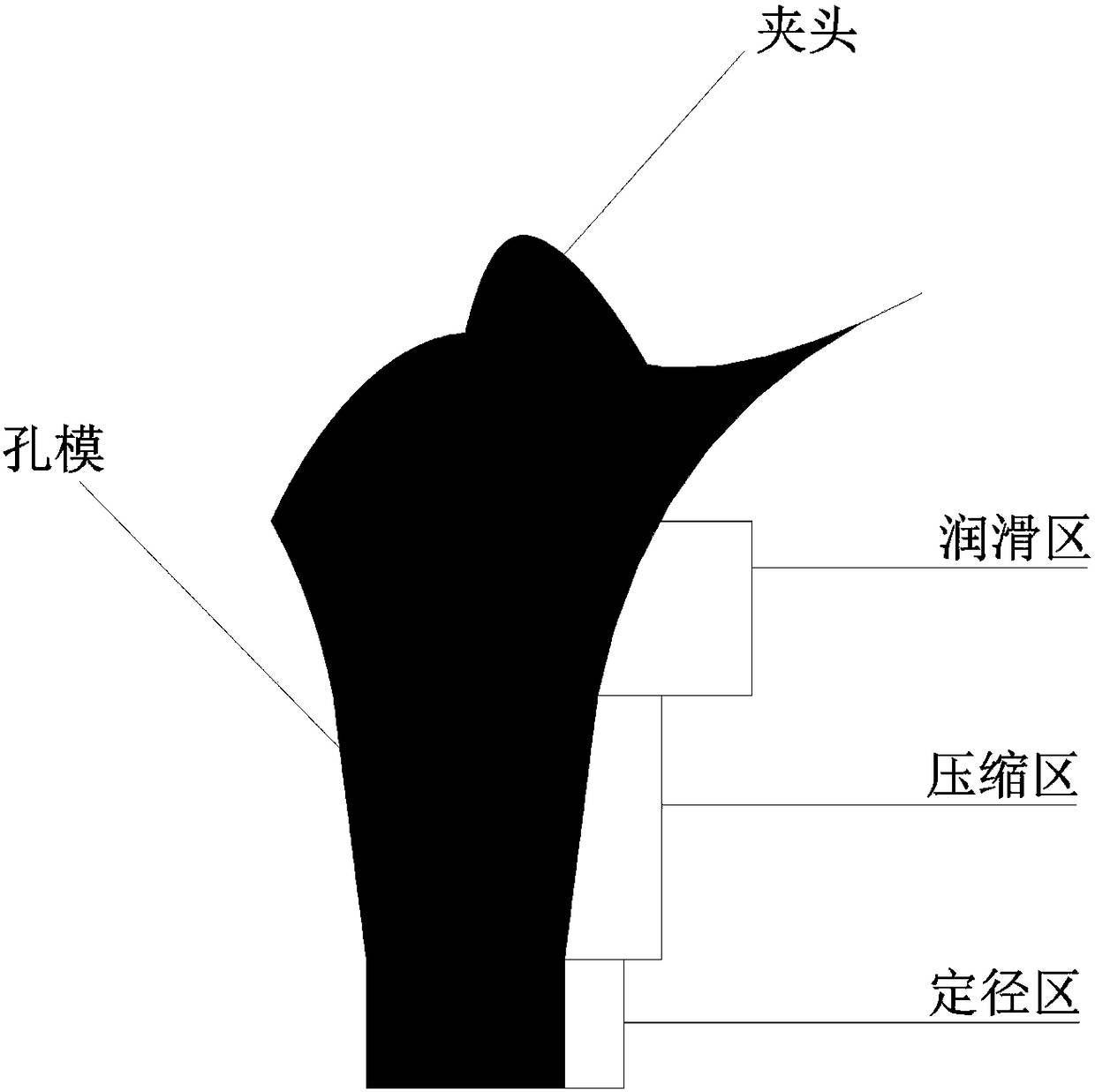

[0025] Such as Figure 1-3 As shown, the rapid surveying and mapping method of a CVD diamond-coated wire drawing die provided by the present invention has scientific and reasonable design, simple operation, high surveying and mapping efficiency, high surveying and mapping accuracy, and the equipment and materials used are simple and low in cost. The present invention comprises the following steps:

[0026] (1) Place the drawing die in an ultrasonic cleaning machine and take it out after cleaning for 30 seconds;

[0027] (2) Place the wire drawing die cleaned in step (1) in a constant temperature drying box and bake for 30 minutes, the baking temperature of the constant temperature drying box is 35°C;

[0028] (3) Take out the wire drawing mold baked in step (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com