High-valued comprehensive utilization method of lithium slag

A technology for lithium slag and tailings, which is applied in the field of high-value green comprehensive utilization and treatment of lithium slag, can solve the problems of single application of lithium slag, such as recovery and treatment, limited application development, high price of spodumene, etc., and achieves increased added value. , the effect of saving usage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

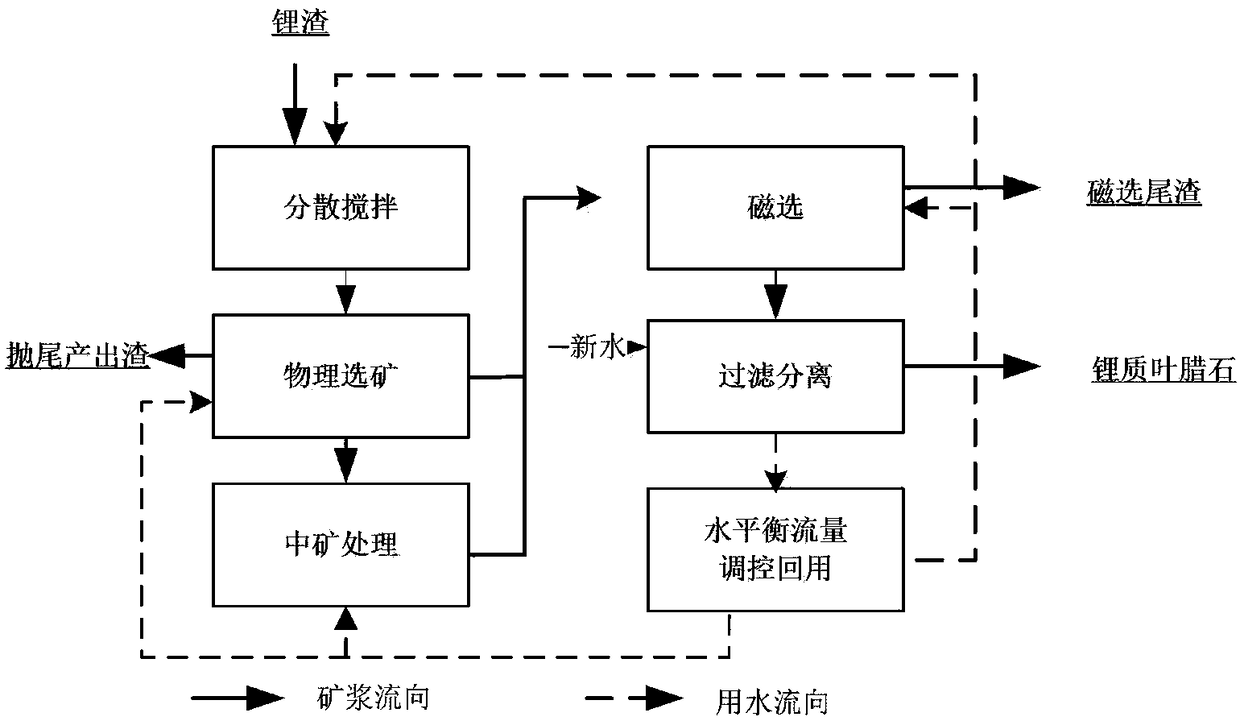

Method used

Image

Examples

Embodiment 1

[0069] For a spodumene lithium extraction enterprise in Sichuan, the lithium slag (Li 2 O 0.3%, SO 3 6.58%, Fe 2 o 3 1.8%, SiO 2 62%, Al 2 o 3 21%), add water to adjust slurry, pulp concentration 40%, and add dispersant sodium silicate 1000 grams / ton lithium slag; Ore pulp enters desulfurization process, at first ore pulp enters flotation desulfurization, what flotation collector adopts is oleic acid, The flotation process adopts primary roughing and secondary sweeping. The dosage of oleic acid for roughing collector is 100g / ton lithium slag, the amount of oleic acid collector for primary sweeping is 50g / ton lithium residue, and the amount of oleic acid for secondary sweeping is The amount of oleic acid collector is 50g / ton of lithium slag, the foamed product of flotation is used as gypsum putty, and the non-foamed product of flotation operation enters the wet strong magnetic separator. Control the magnetic field strength to 1.2T, sweep and control the magnetic field str...

Embodiment 2

[0077] For a spodumene lithium extraction enterprise in Sichuan, the lithium slag (Li 2 O 0.5%, SO 3 11.05%, Fe 2 o 3 0.85%, SiO 2 55%, Al 2 o 3 21%), add water to adjust slurry, pulp concentration 50%, and add dispersant sodium silicate 1500 g / t lithium slag; ore pulp enters desulfurization process, first ore pulp enters hydrocyclone for gravity separation, and the specific gravity obtained by gravity separation is relatively Larger products enter flotation desulfurization, the flotation collector uses dodecylamine, the flotation process adopts one roughing and two sweeping, and the amount of roughing collector dodecylamine is 50g / ton of lithium slag , the amount of dodecylamine used as a collector in the first sweep is 25g / ton of lithium slag, and the dosage of dodecylamine in the second sweep is 10g / ton of lithium slag. As gypsum putty, the non-foam product of flotation operation enters the strong magnetic separator, and what the strong magnetic separation adopts is a...

Embodiment 3

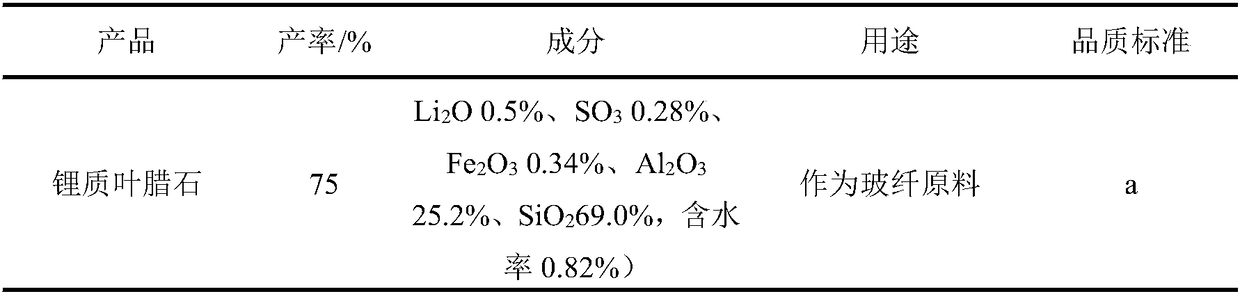

[0084] Lithium slag (Li 2 O 0.27%, SO 3 1.92%, Fe 2 o 3 1.13%, SiO 2 67%, Al 2 o 3 23%), add water through the mortar pump to adjust the slurry and pour it into the mixing tank to control the concentration of the ore slurry to 30%. The ore slurry enters the flotation column for flotation. Lithium slag is 50g / ton, and the amount of oleic acid used as a collector in one sweep is 20g / ton lithium slag. The non-foam products obtained by flotation enter the strong magnetic separator. The control magnetic field strength is 1.5T, and the sweeping control magnetic field strength is 1.8T. After magnetic separation, the obtained magnetic separation slurry is concentrated, filtered and dried to obtain a lithium pyrophyllite product for glass fiber. The specific product parameters are shown in Table 3.

[0085] table 3

[0086]

[0087] Note: the market price of the cement admixture obtained in this embodiment is about 50 yuan / ton, and the market price of the obtained gypsum put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com