Preparation of catalyst for oil and fat hydrogenation, catalyst and application

A technology for oil hydrogenation and catalyst, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical instrument and method, etc., which can solve the problem that the selectivity and yield of target products are reduced and the probability is increased. , the probability of cracking at the insertion end, etc., to achieve the effect of improving freezing point, high isomer selectivity, and increasing diesel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

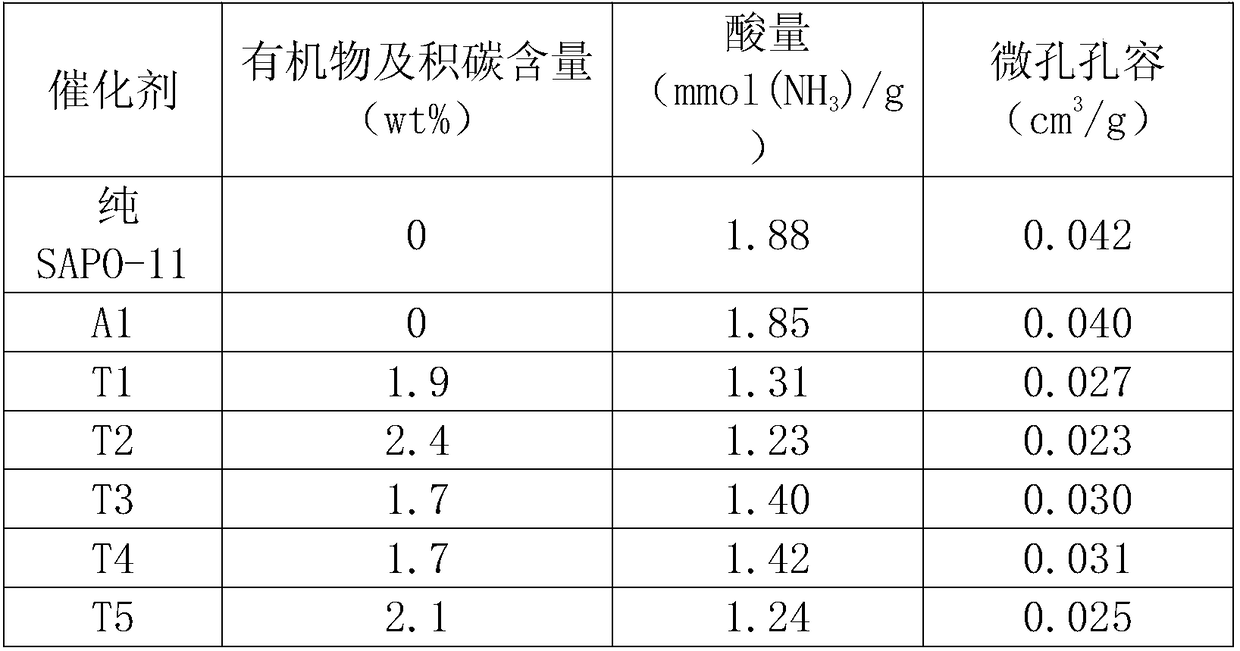

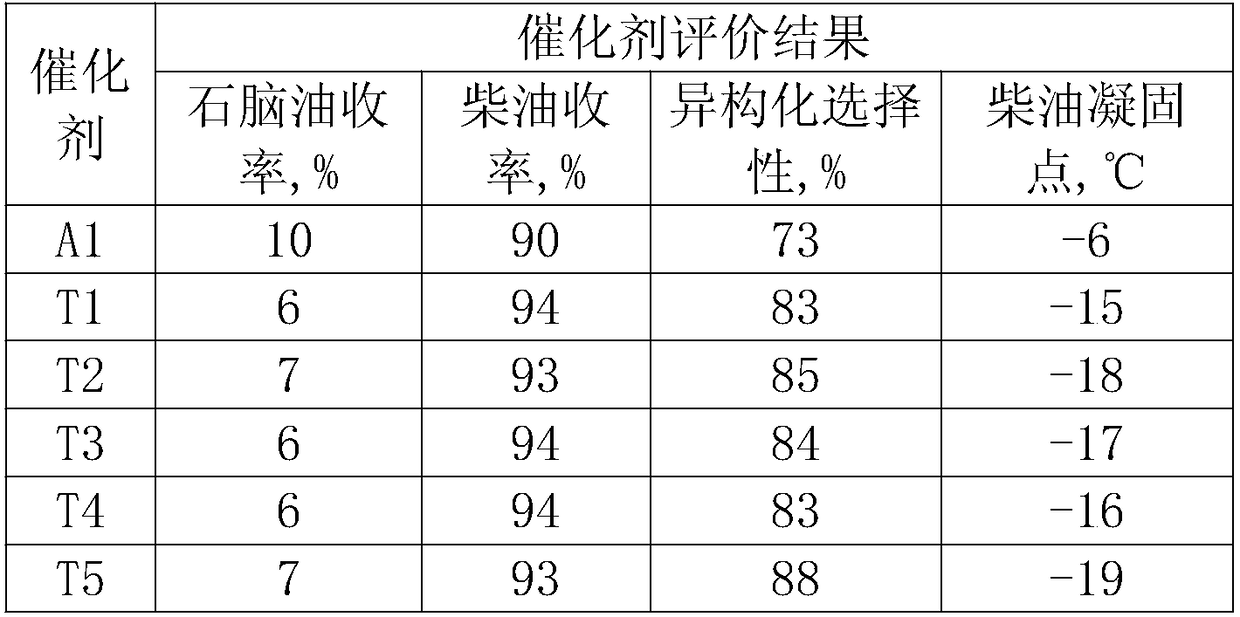

Embodiment 1

[0070] Take 120g of the SAPO-11 molecular sieve raw powder containing the template, and roast it under an air atmosphere at 550°C for 24h to obtain 100g of the SAPO-11 molecular sieve from which the template has been completely removed; take 30g of pseudoboehmite (alumina hydrate) with it Mix well, add 80g 5wt% HNO 3 solution, kneaded, molded with extruder, dried naturally, then dried at 120°C for 4h, and roasted at 550°C for 12h to obtain the carrier precursor; 100mL furfuryl alcohol and 100mL ethanol were mixed and stirred evenly at 25°C, and 1g oxalic acid was added to it , after dissolving completely, obtain monomer solution; Take 50g carrier precursor and mix with 50g monomer solution, place 6h under 25 ℃, obtain the carrier precursor of adsorption monomer solution after filtration and dry 0.5h at 120 ℃ (while drying, The polymer monomer furfuryl alcohol adsorbed by the carrier precursor undergoes spontaneous condensation reaction under heating and acidic environment), an...

Embodiment 2

[0072] Take 120g of the SAPO-11 molecular sieve raw powder containing the template, and roast it under an air atmosphere at 550°C for 24h to obtain 100g of the SAPO-11 molecular sieve from which the template has been completely removed; take 30g of pseudoboehmite (alumina hydrate) with it Mix well, add 80g 5wt% HNO 3 solution, kneaded, shaped by extruder, dried naturally, then dried at 120°C for 4h, and roasted at 550°C for 12h to obtain the carrier precursor; 100mL furfural and 100mL ethanol were mixed and stirred evenly at 25°C, and 1g oxalic acid was added to it , after dissolving completely, obtain monomer solution; Take 50g carrier precursor and mix with 50g monomer solution, place 6h under 25 ℃, obtain the carrier precursor of adsorption monomer solution after filtration and dry 0.5h at 120 ℃ (while drying, The polymer monomer furfural adsorbed by the carrier precursor undergoes spontaneous condensation reaction under heating and acidic environment), and then placed in a...

Embodiment 3

[0074] Take 120g of the SAPO-11 molecular sieve raw powder containing the template, and roast it in an air atmosphere at 550°C for 24h to obtain 100g of the SAPO-11 molecular sieve from which the template has been completely removed; take 20g of pseudoboehmite (alumina hydrate) with it Mix well, add 80g 5wt% HNO 3 solution, kneaded, formed with extruder, dried naturally, then dried at 120°C for 4h, and roasted at 550°C for 12h to obtain the carrier precursor; 100mL furfural and 50mL ethanol were mixed and stirred at 25°C, and 5mL Hydrochloric acid, after dissolving completely, obtains monomer solution; Get 50g carrier precursor and mix with 50g monomer solution, place 6h under 25 ℃, after filtering, obtain the carrier precursor of adsorption monomer solution and dry at 120 ℃ for 0.5h (while drying , the polymer monomer furfural adsorbed by the carrier precursor undergoes spontaneous condensation reaction under heating and acidic environment), and then placed in a quartz tube, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com