A kind of preparation method of C5, C6 alkane isomerization catalyst

A technology for alkane isomerization and catalysts, which is applied in the field of preparation of C5 and C6 alkane isomerization catalysts, can solve the problems such as metal dispersion has not been improved, and achieve the effects of reducing exchange reaction rate, increasing activity and reducing acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Take 160g of dried 1# mordenite molecular sieve, 40g of pseudoboehmite, 2g of methyl cellulose, and 40mL of dilute nitric acid with a weight concentration of 3%, mix the above materials, knead and extrude into strands, and dry at 110°C for 2h. Then the temperature was raised to 480° C. at 3° C. / min, and calcined for 3 hours to obtain the molded carrier Z-1.

Embodiment 2

[0039] The carrier was prepared according to the method of Example 1, except that the dried 2# mordenite molecular sieve was used, and the prepared carrier was designated as Z-2.

Embodiment 3

[0041] The carrier was prepared according to the method of Example 1, except that dried 3# mordenite molecular sieve was used, and the prepared carrier was marked as Z-3.

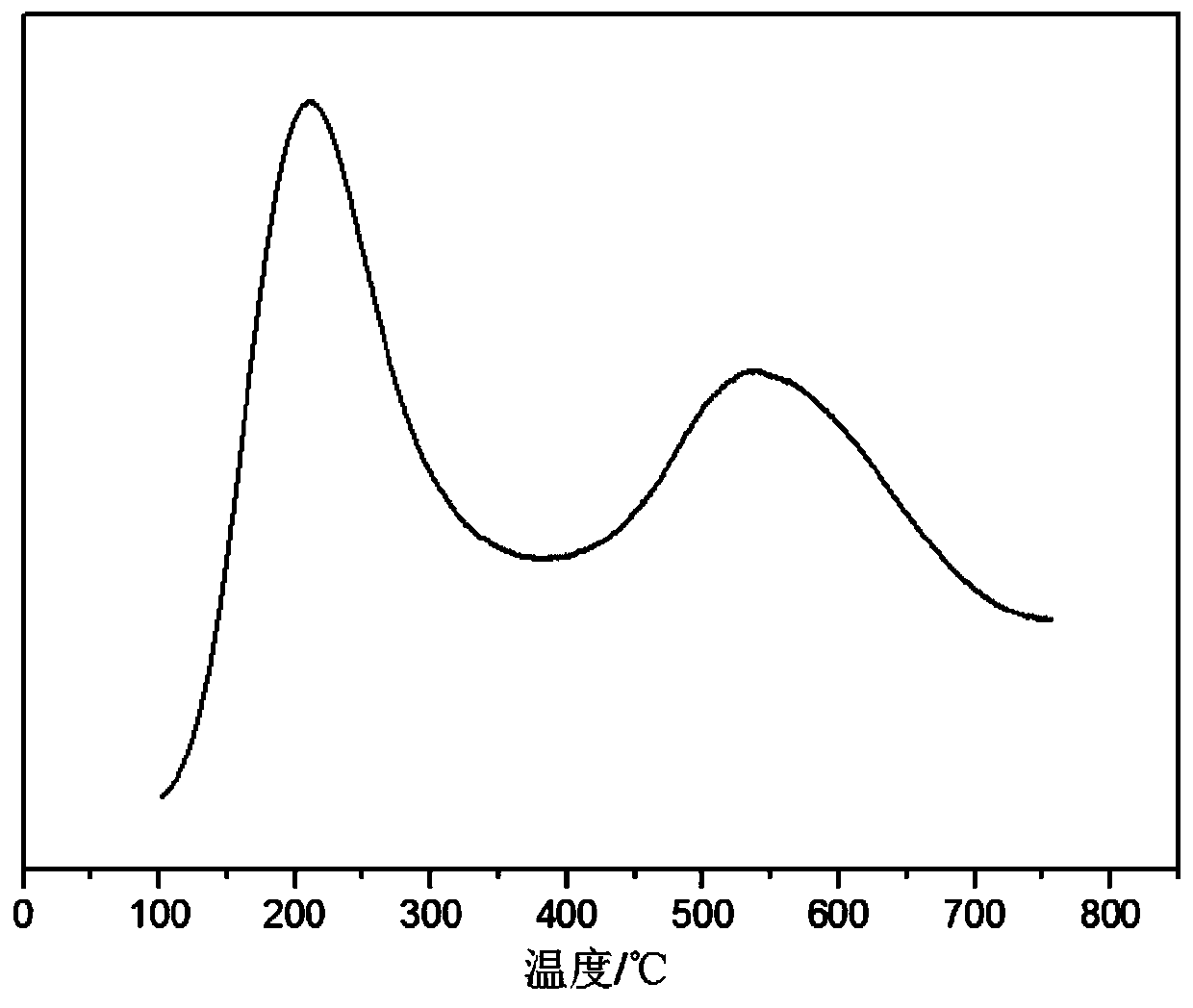

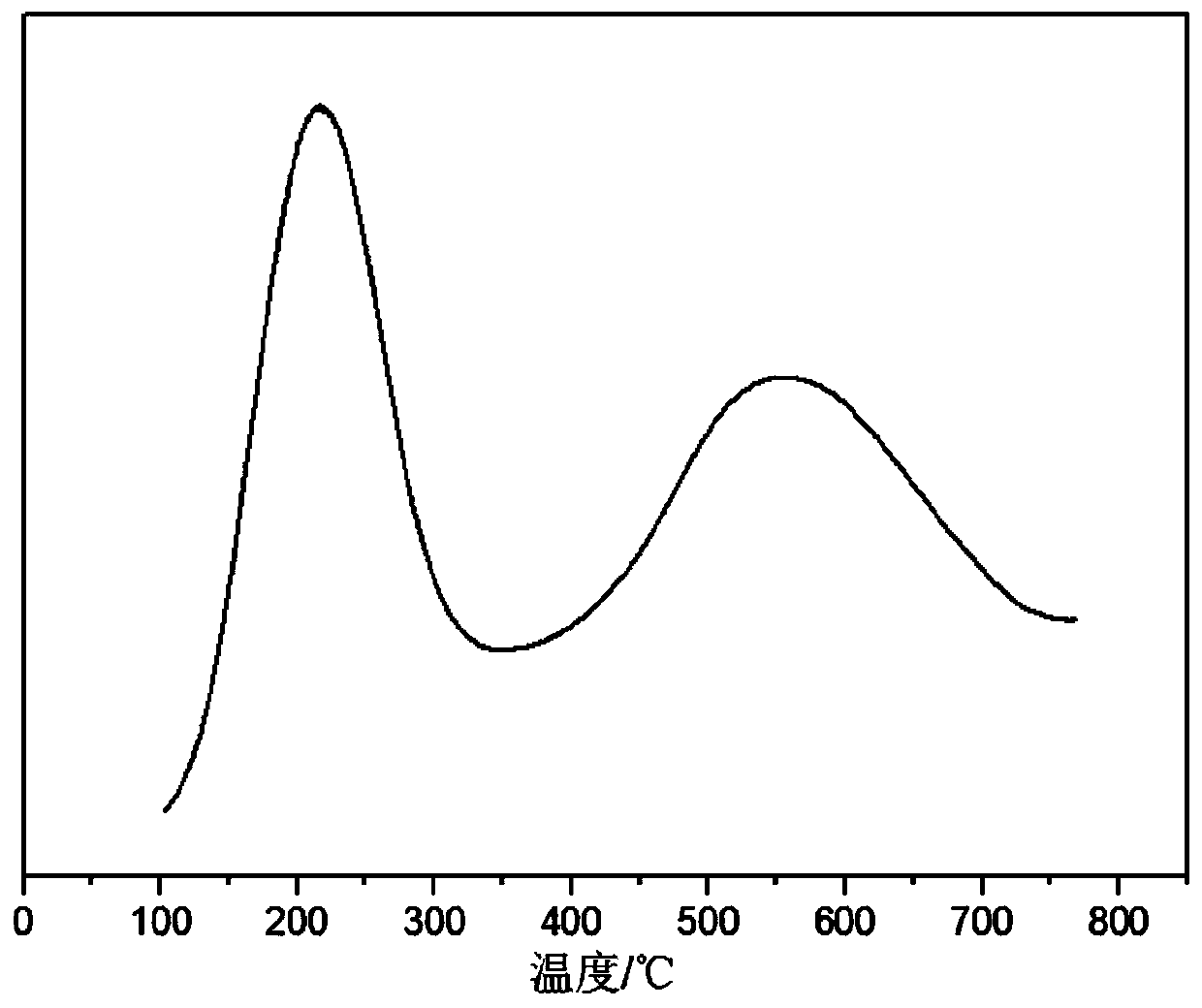

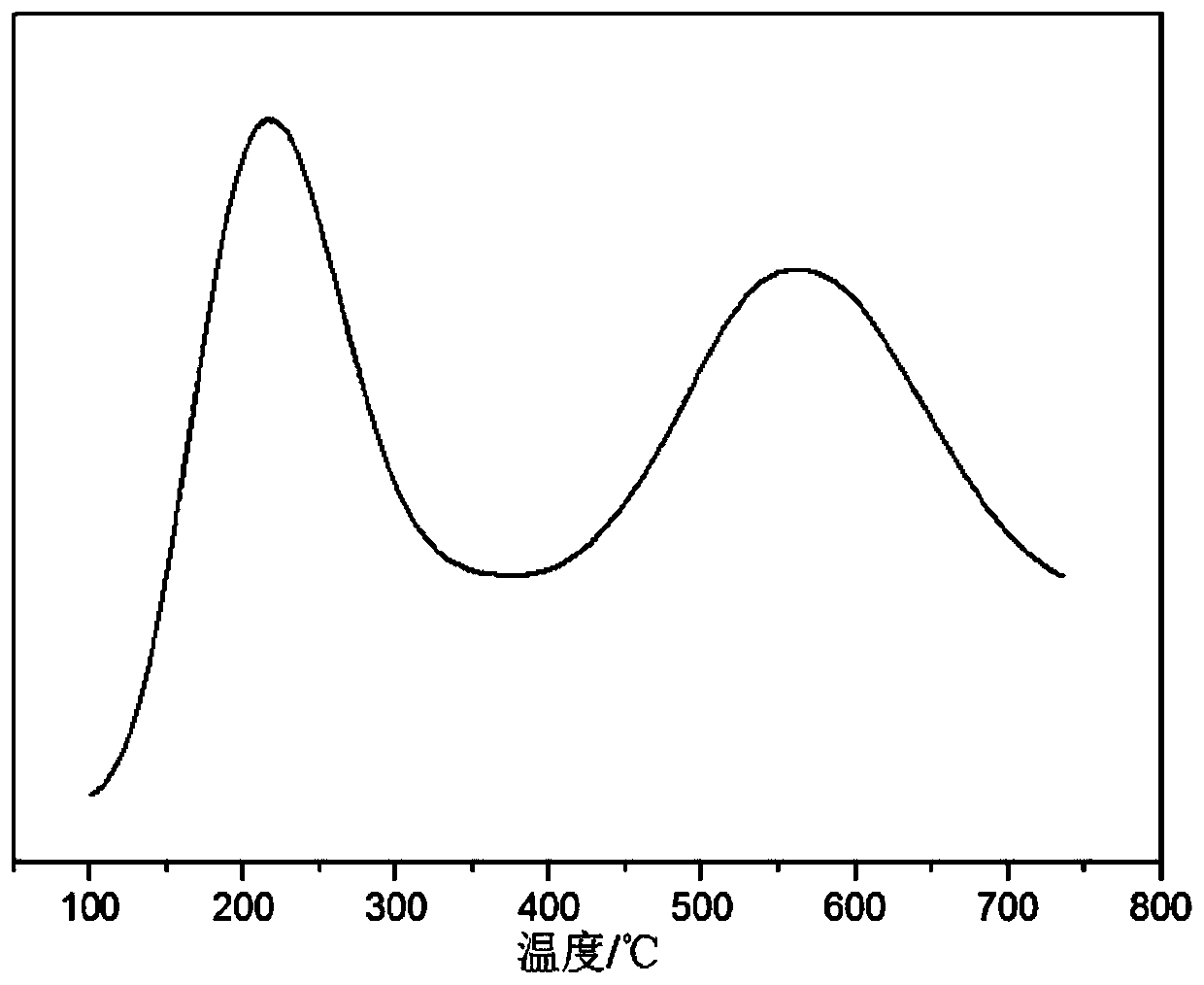

[0042] NH of the carrier prepared in Examples 1-3 3 -TPD detection result is shown in table 2, appendix Figure 1-3 NH corresponding to Z-1, Z-2, Z-3 3 Desorption peak spectrum.

[0043] Table 2 NH of the carrier after molding 3 -TPD results

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com