Mutli-layer protective type diaper and method for making diaper

A technology for diapers and fabric layers, applied in the field of diapers, can solve the problems of high price and improvement of raw materials, and achieve the effects of improving antibacterial properties, improving overall strength and excellent moisture removal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment discloses a multi-layer protective diaper, which is composed of an antibacterial and deodorant fabric layer, a sweat-absorbing and moisture-conducting fabric layer, a water-absorbing non-woven fabric layer, and a surface layer sequentially from the inside to the outside. In some diapers, a diversion layer is compounded between the sweat-absorbing and moisture-conducting fabric layer and the antibacterial and deodorant fabric layer.

Embodiment 2

[0059] This embodiment discloses a preparation method of an antibacterial and deodorant fabric, comprising the following steps:

[0060] (1) Bamboo fibers were selected, ground into fiber fragments with a length of 2mm, and the fiber fragments were cooked in alkaline cooking liquid at 110° C. for 2 hours, and then filtered to obtain bamboo fiber pulp.

[0061] (2) Add dihydroxypropyl chitosan to the bamboo fiber pulp in step (1), and mix it at 40°C for 2 hours in NaOH, thiourea, urea, and water solvent system to obtain dihydroxypropyl chitosan Chitosan / bamboo fiber pulp hybrid system. Wherein, the mass ratio of dihydroxypropyl chitosan to bamboo fiber pulp is 1:40. The mass ratio of the total amount of dihydroxypropyl chitosan and bamboo fiber pulp to the NaOH, thiourea, urea, and water solvent system is 1:5.

[0062] (3) Add nano-titanium dioxide, nano-molybdenum dioxide, and aloe extract to the chitosan / bamboo fiber slurry mixing system in step (2), and mix for 30 minutes ...

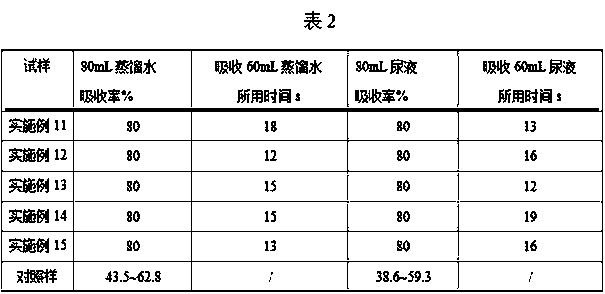

Embodiment 3

[0067] This embodiment discloses a preparation method of an antibacterial and deodorant fabric, comprising the following steps:

[0068] (1) Bamboo fibers were selected, ground into fiber fragments with a length of 5 mm, and the fiber fragments were cooked in an alkaline cooking solution at 130° C. for 1 hour, and then filtered to obtain bamboo fiber pulp.

[0069] (2) Add dihydroxypropyl chitosan to the bamboo fiber pulp in step (1), and mix it at 60°C for 1 hour in NaOH, thiourea, urea, and water solvent system to obtain dihydroxypropyl chitosan Chitosan / bamboo fiber pulp hybrid system. Wherein, the mass ratio of dihydroxypropyl chitosan to bamboo fiber pulp is 1:10. The mass ratio of the total amount of dihydroxypropyl chitosan and bamboo fiber pulp to the NaOH, thiourea, urea, and water solvent system is 1:8.

[0070](3) Add nano-titanium dioxide, nano-molybdenum dioxide, aloe vera extract, and lemongrass extract into the chitosan / bamboo fiber slurry mixing system in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com