Shielding metamaterial with zero magnetic conductivity for wireless charging of electric cars

A wireless charging and electric vehicle technology, applied in the electromagnetic field, can solve the problems of high loss, unfavorable wireless coupling system simplicity and practicality, and heavy weight, and achieve the effect of strong electromagnetic shielding characteristics, shielding electromagnetic radiation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

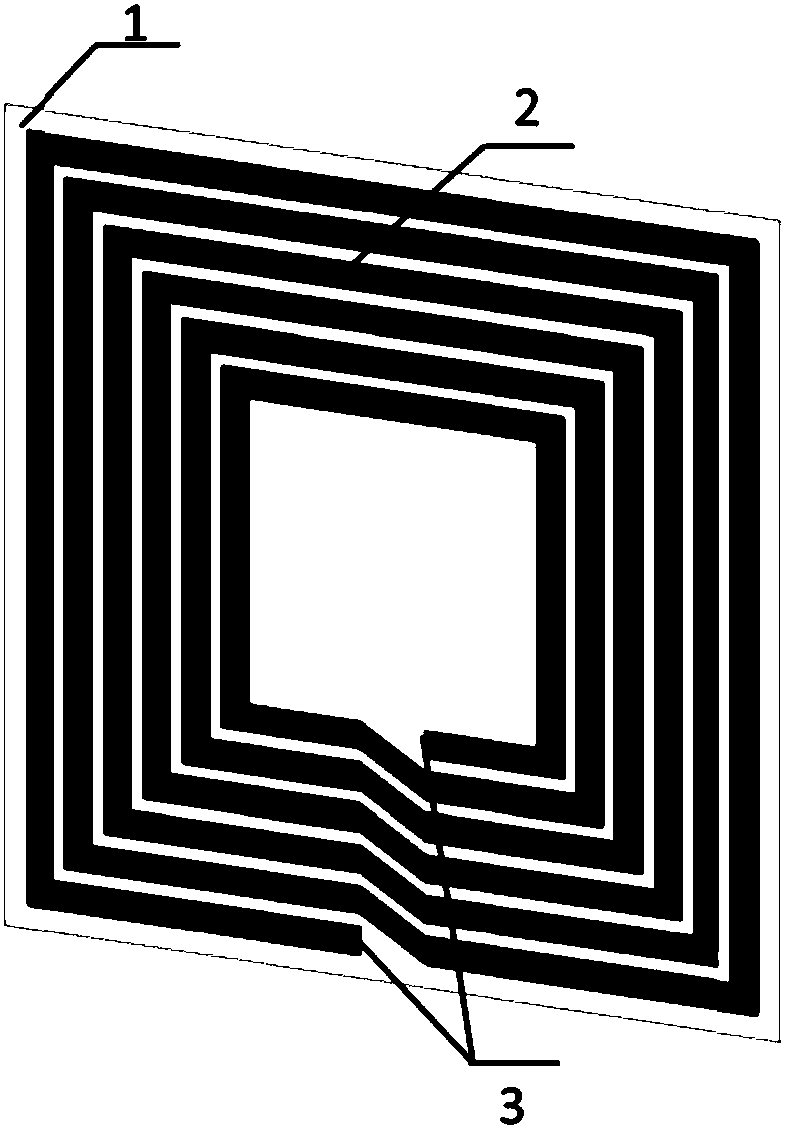

Image

Examples

Embodiment 2

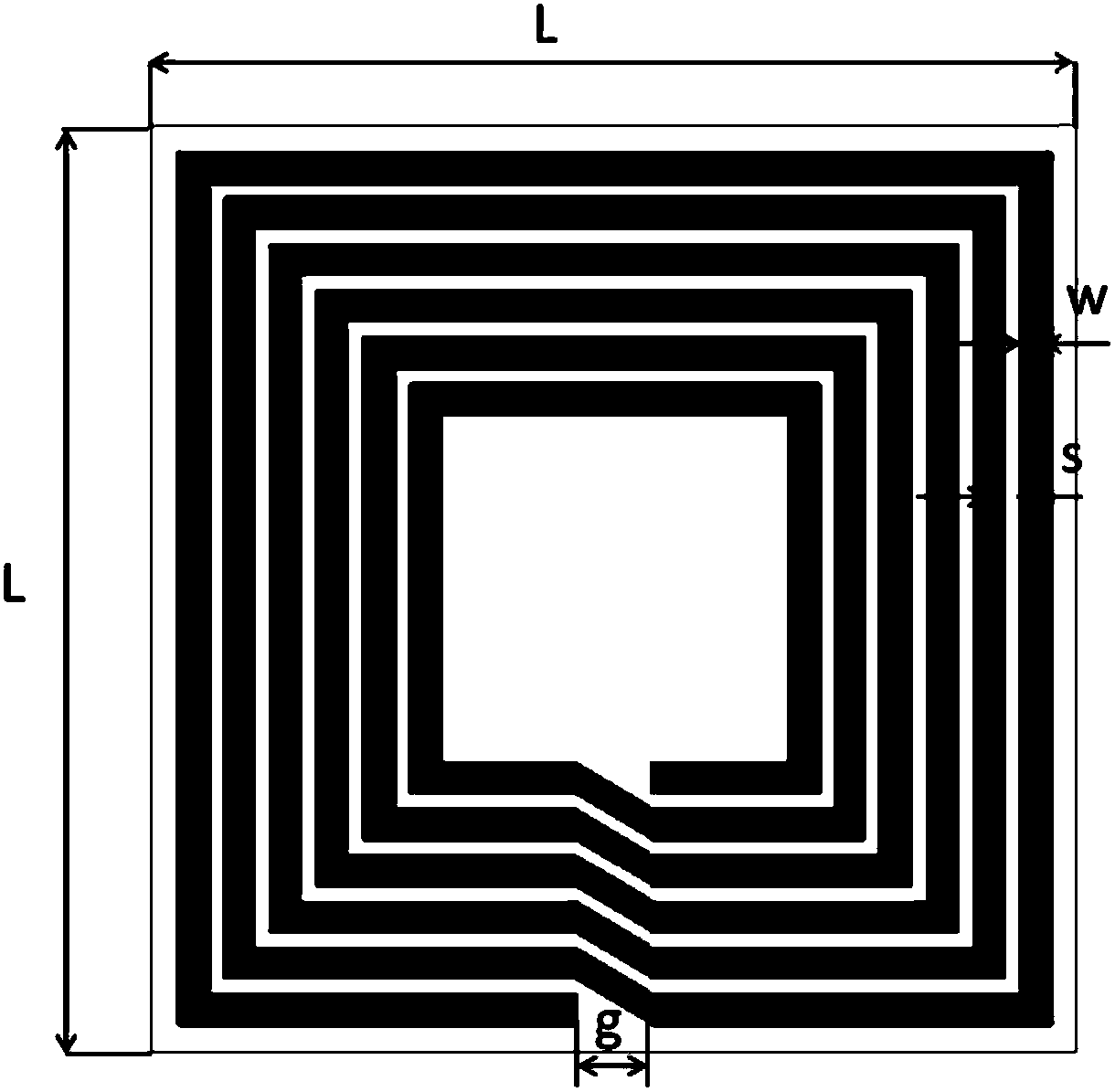

[0037] The technical parameters used in the simulation of embodiment 2 are: the copper wire width w is 1mm, the line spacing s is 1mm, the number of coil turns is 7 turns, the opening spacing g is 5mm, the substrate is an FR-4 substrate, and the dielectric constant is 4.2. The loss tangent value is 0.02, the thickness is 2mm, the size of the metamaterial is 120mm×120mm, that is, L=120mm, and the capacitance of the high-voltage in-line CBB capacitor is 1uf. The metamaterial in this specific embodiment corresponds to zero magnetic permeability around 85KHz, and the metamaterial can be produced by PCB printing technology, which is beneficial to mass production of the metamaterial at low cost.

Embodiment 3

[0038] The technical parameters used in the simulation of embodiment 3 are: the copper wire width w is 6mm, the line spacing s is 4mm, the number of coil turns is 3 turns, the opening spacing g is 20mm, the substrate is an FR-4 substrate, and the dielectric constant is 4.6. The loss tangent value is 0.02, the thickness is 2mm, the size of the metamaterial is 120mm×120mm, that is, L=120mm, and the capacitance of the high-voltage in-line CBB capacitor is 1.4uf. The metamaterial in this specific embodiment corresponds to zero magnetic permeability around 85KHz, and the metamaterial can be produced by PCB printing technology, which is beneficial to mass production of the metamaterial at low cost.

Embodiment 4

[0039]The technical parameters used in the simulation of embodiment 4 are: the copper wire width w is 1mm, the line spacing s is 4mm, the number of coil turns is 7 turns, the opening spacing g is 5mm, the substrate is an FR-4 substrate, and the dielectric constant is 4.2. The loss tangent value is 0.02, the thickness is 2mm, the size of the metamaterial is 120mm×120mm, that is, L=120mm, and the capacitance of the high-voltage in-line CBB capacitor is 1.4uf. The metamaterial in this specific embodiment corresponds to zero magnetic permeability around 85KHz, and the metamaterial can be produced by PCB printing technology, which is beneficial to mass production of the metamaterial at low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com