Aluminum sulfur composite material as well as preparation method and application thereof

A technology of composite materials and aluminum balls, applied in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of too fast attenuation in the cycle process, few considerations, low sulfur utilization rate, etc., to improve the rate performance And cycle performance, reduce the volume change rate, improve the effect of sulfur utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

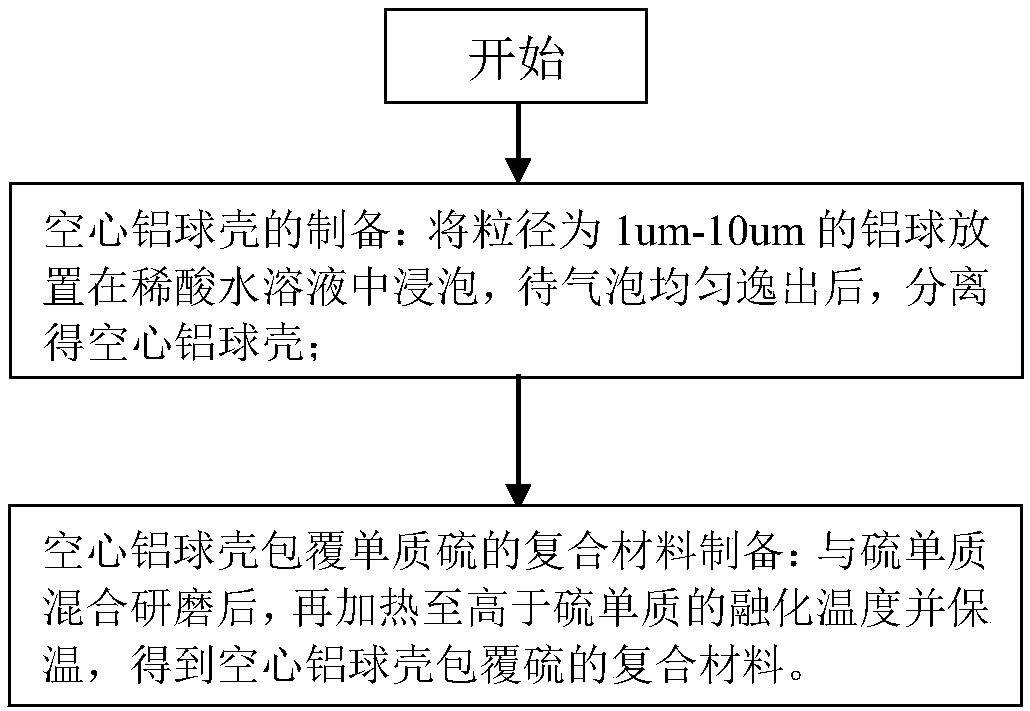

[0036] The present application also includes the preparation method of the aluminum-sulfur composite material, combining figure 1 As shown, it specifically includes the following steps:

[0037] (1) Preparation of hollow aluminum spherical shells: soak aluminum balls with a particle size of 1um-10um in dilute acid aqueous solution, and separate the aluminum balls after the bubbles escape evenly to obtain hollow aluminum spherical shells with pores distributed on the surface;

[0038] (2) Preparation of composite material of hollow aluminum spherical shell coated elemental sulfur: the hollow aluminum spherical shell obtained in step (1) and sulfur elemental are mixed and ground according to a certain mass ratio, then the mixture is put into a reactor, heated to make the reactor The temperature is higher than the melting temperature of sulfur element but lower than its flash point temperature (in this application generally refers to 113 ° C ~ 170 ° C) and heat preservation, to o...

example 1

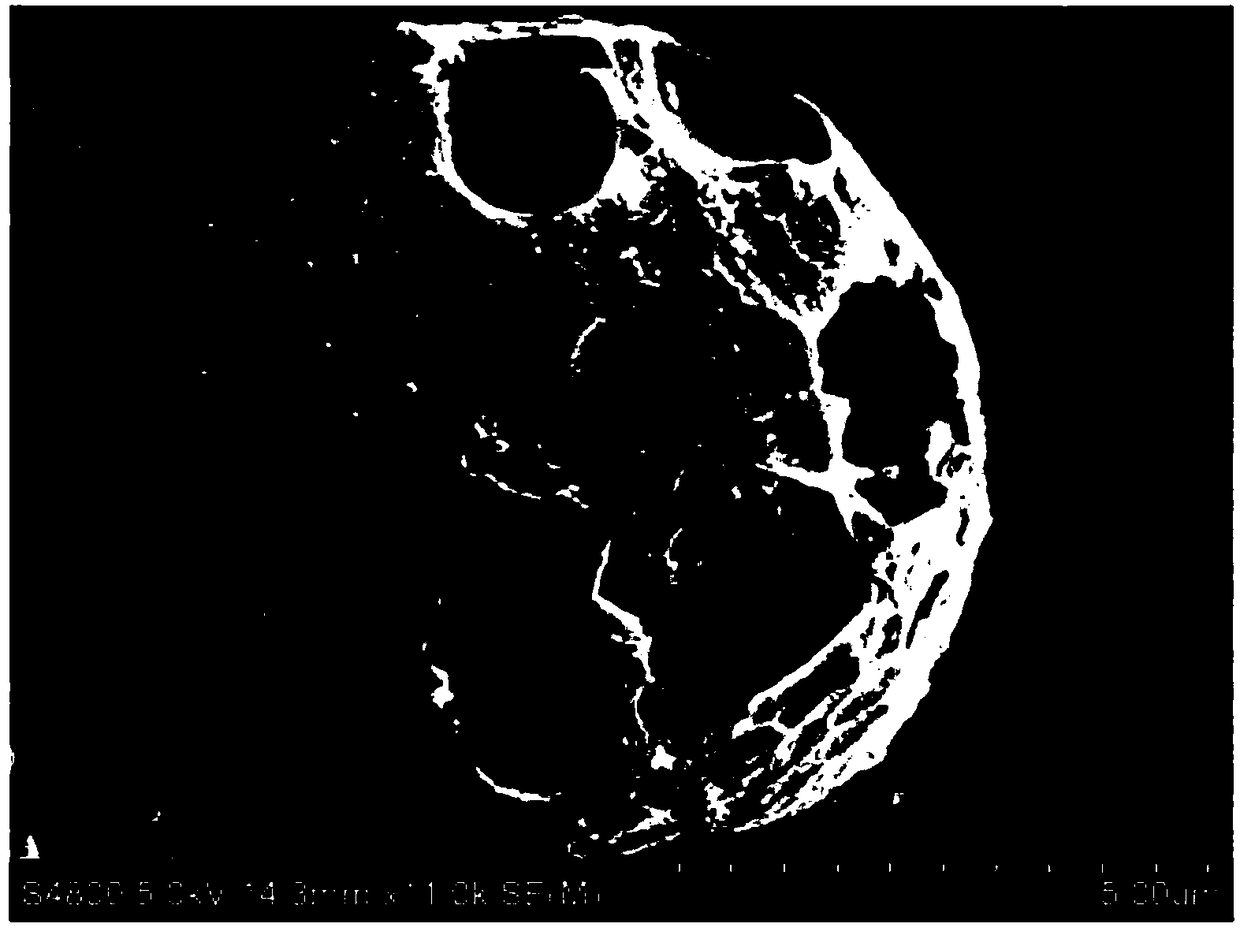

[0042] Select aluminum balls with a particle size of 10um, prepare 1mol / L hydrochloric acid aqueous solution, soak the aluminum balls for 2 hours, wait for the bubbles to escape uniformly for about 0.5h, and then filter out the aluminum powder. Washing with deionized water, suction filtration, and drying to obtain hollow aluminum spherical shells. The prepared hollow aluminum spherical shell and sulfur powder were high-energy ball milled for 4 hours according to the mass ratio of 30:70, and then the prepared powder was put into a 200ML reactor, heated to 160°C, and kept for 4 hours to obtain a hollow aluminum shell. A composite material of aluminum spherical shell coated with elemental sulfur, which is used as the positive electrode material of lithium-sulfur battery.

[0043] Place the composite material of the hollow aluminum spherical shell coated with elemental sulfur obtained in this example under a scanning electron microscope to observe its morphology, as shown in fig...

example 2

[0045] Select aluminum balls with a particle size of 1um, prepare 0.1mol / L hydrochloric acid aqueous solution, soak the aluminum balls for 2 hours, wait for the bubbles to escape uniformly for about 1 hour, and then filter out the aluminum powder. Washing with deionized water, suction filtration, and drying to obtain hollow aluminum spherical shells. The prepared hollow aluminum spherical shell and sulfur powder were high-energy ball milled for 2 hours according to the mass ratio of 30:70, and then the prepared powder was put into a 200ML reaction kettle, heated to 150°C, and kept for 4 hours to obtain a hollow aluminum shell. A composite material of aluminum spherical shell coated with elemental sulfur, which is used as the positive electrode material of lithium-sulfur battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com