A cold chain storage and transportation monitoring label based on nano temperature-sensitive color-changing materials

A temperature-sensitive color-changing and labeling technology, which is applied to identification devices, instruments, stamps, etc., can solve the problems of narrow application range, poor mechanical properties, and high price, and achieve the effect of high technical threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

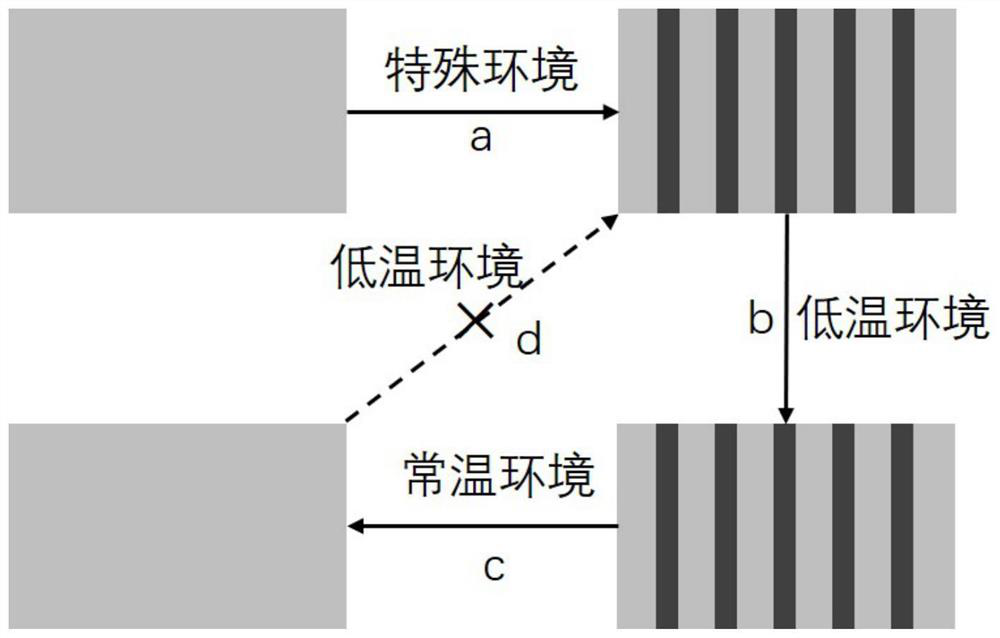

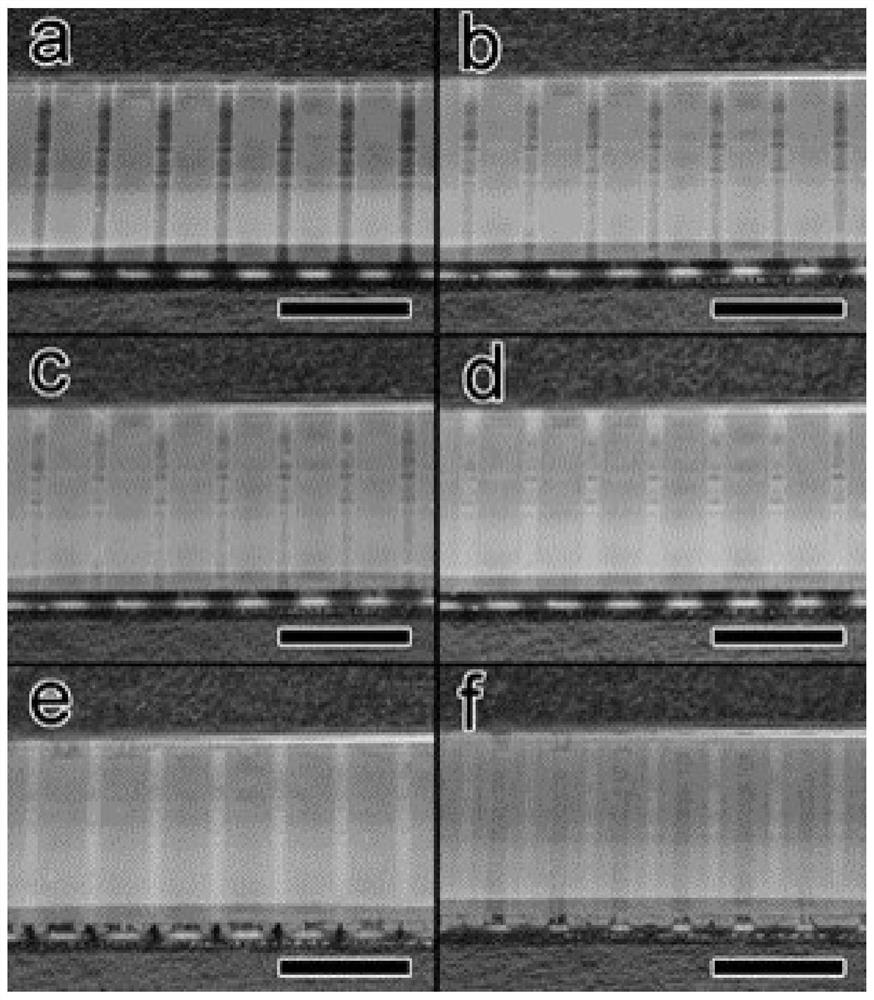

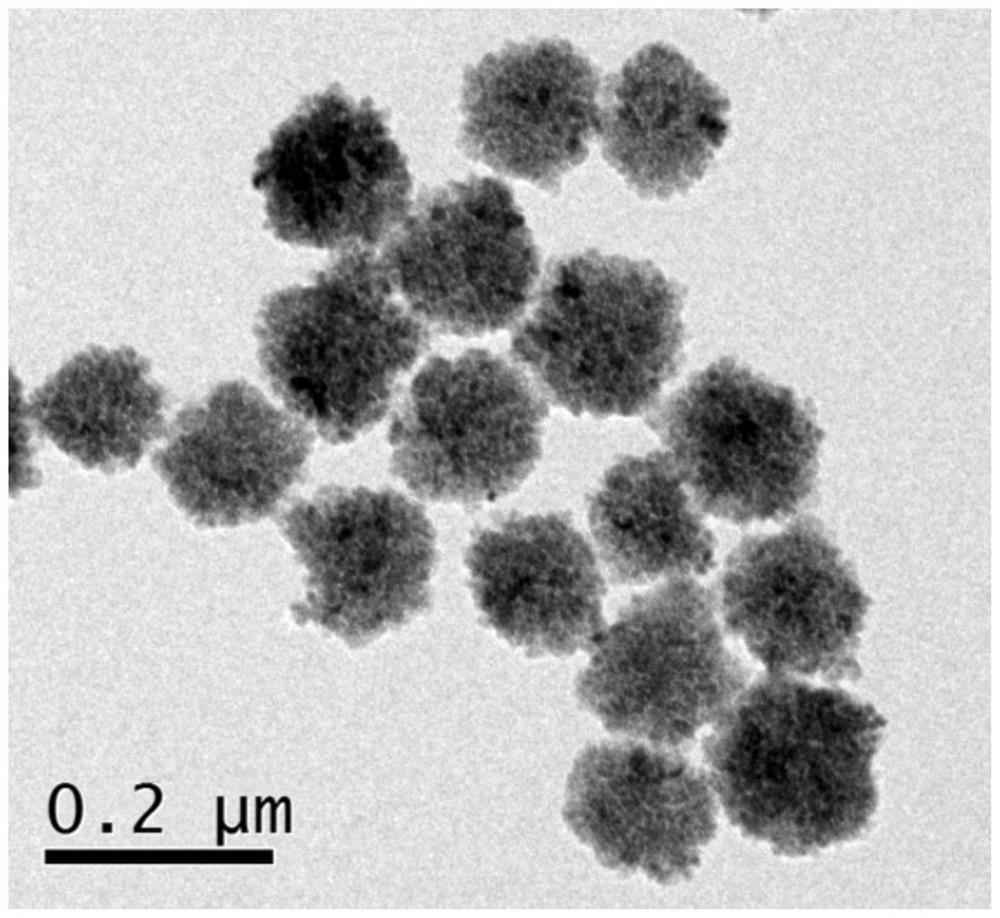

[0015] This embodiment demonstrates the implementation process of using a metastable photonic crystal for a label. The composition of the temperature-sensitive label is 10% by volume fraction of photonic crystal nanoparticles, 50% by volume fraction of water and 40% by volume fraction of diethylene glycol. Patterns are formed under external special magnetic field and low temperature conditions (3-5 degrees Celsius), such as figure 1 Process a: Place the patterned label in a refrigerator at 5 degrees Celsius, and no obvious color change was observed during the experiment period ( figure 1 Process b); when the ratio of the temperature-sensitive material exceeds 8 degrees Celsius, due to the increase in temperature, the fluidity of the liquid will increase, and the original photonic crystal structure will not be maintained, so that the color and pattern will gradually change until they disappear ( figure 1 Process c), here we take out the label and place it at room temperature (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com