Chemico-mechanical polishing solution for phase-change material GeSbTe

A chemical mechanical and polishing fluid technology, applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of low polishing selection ratio, GeSbTe corrosion pits, and low polishing rate, so as to improve polishing rate, reduce surface corrosion, and high efficiency The effect of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Abrasive: 2wt.% 50nm ammonia colloidal SiO 2

[0044] Oxidant type and content: 1wt.% H 2 o 2

[0045] Type and content of surface protective agent: 200ppm guar gum

[0046] Amino acid organic additives: 0.5wt.% cysteine

[0047] pH: 4.5

[0048]The polishing test results are shown in Table 1.

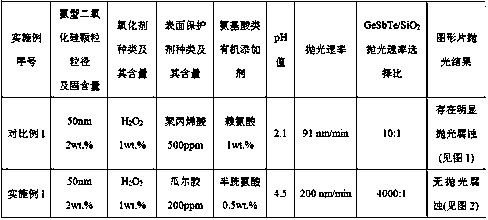

[0049] Table 1 Comparison of polishing performance of Comparative Example 1 and Example 1.

[0050]

[0051] It can be seen from Table 1 that when using Comparative Example 1, the GeSbTe polishing rate is low, only 91nm / min, and GeSbTe / SiO 2 The polishing selection ratio is 10:1. figure 1 The SEM cross-sectional view of the GeSbTe graphic sheet polished using Comparative Example 1 is given. It can be seen from the figure that the GeSbTe in the nanopore of the phase change unit is basically completely corroded, and only a small amount of GeSbTe remains at the bottom of the nanopore. Example 1 uses the polishing solution provided by the present invention. It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com