Composite spraying material and frame for downhole quick leaking stoppage and filling and implementing method thereof

A kind of spraying material and fast technology, applied in the direction of fireproof coating, conductive coating, drilling composition, etc., can solve the problems of high cost and large negative impact, and achieve the effect of flexible deformation, reducing air leakage rate and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

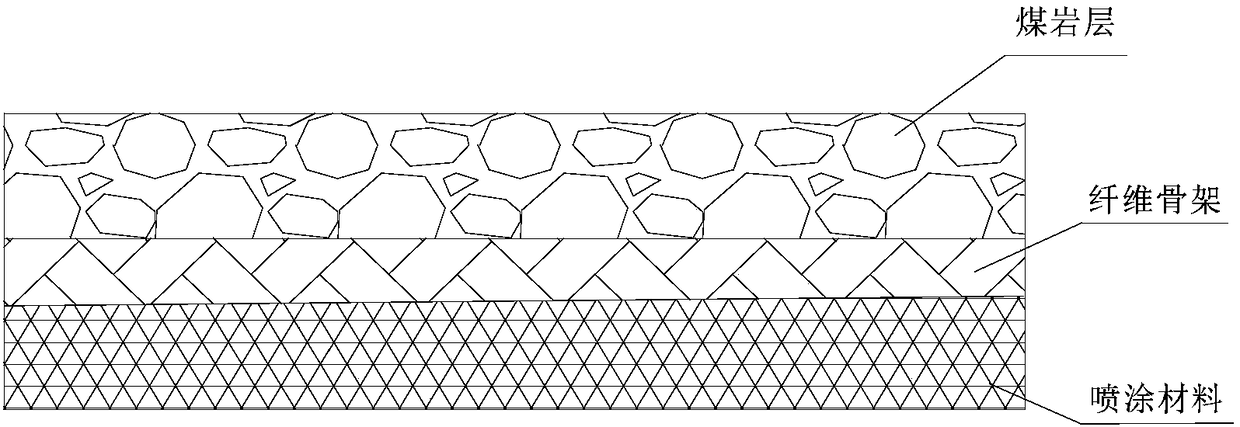

Image

Examples

Embodiment 1

[0048] Example 1, with the improvement of the level of comprehensive mechanized mining, more and more working faces are mined without coal pillars. During the process of roadway formation with roof cutting and goaf retention, relatively large cracks are likely to occur between the roof and floor of the roadway, resulting in mining A large amount of air leakage in the goaf has created conditions for the spontaneous combustion of coal left in the goaf. Therefore, the use of a sealed skeleton structure to connect the roadway retention with the roof and floor, followed by spraying composite polymer materials, can effectively block the air leakage and greatly improve the utilization rate of the sprayed materials, so that the material and the original roadway wall form a whole that is isolated from air leakage. It can effectively maintain the sealing performance of the gap between the roof and floor of the roadway under the influence of the tunnel.

Embodiment 2

[0049] Example 2, during the mining process of the working face, due to factors such as the lithology characteristics of the roof and periodic pressure, it is easy to cause large-scale collapse of the roof of the working face, and the formed roof triangular space provides a place for gas accumulation, resulting in a gas explosion hidden dangers. Therefore, a sealed frame is used to connect the tops of several supports to form a base of composite polymer materials, and a large amount of filling and injection is performed to fill the empty top area. The mixed material penetrates into the interior of the broken coal and rock mass and foams through chemical reactions. , the volume expands, generating additional pressure, further pressing the uncured foam into smaller cracks, and binding the broken and loose rocks together. The construction material has good adhesion and certain compression resistance, which ensures the safe mining of the working face. Such as Figure 5 shown.

Embodiment 3

[0050] Example 3, during the mining process of the working face, due to the gaps between the supports, under the action of the pressure difference between the upper and lower corners, the air leakage of the working face gushes out at the upper corner, which may easily cause the gas in the upper corner of the working face to exceed the limit. At the same time, a large amount of air leakage at the working face has also created good conditions for the spontaneous combustion of residual coal in the goaf, causing major accident hazards. Wind curtains and partition walls at the end of the trough were used to reduce the air leakage of the working face, but the effect was not good. Therefore, at the rear of the hydraulic support in the upper and lower corner sections, a sealed frame is used to connect them into one body, and composite polymer materials are used for spraying to form a good windshield wall. In view of the advantages of the material's shear resistance, light weight and go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com