High-temperature industrial wastewater treatment agent

A wastewater treatment agent and high-temperature industrial technology, applied in water/sewage treatment, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as increasing costs, and achieve low cost, good adsorption effect, and high activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

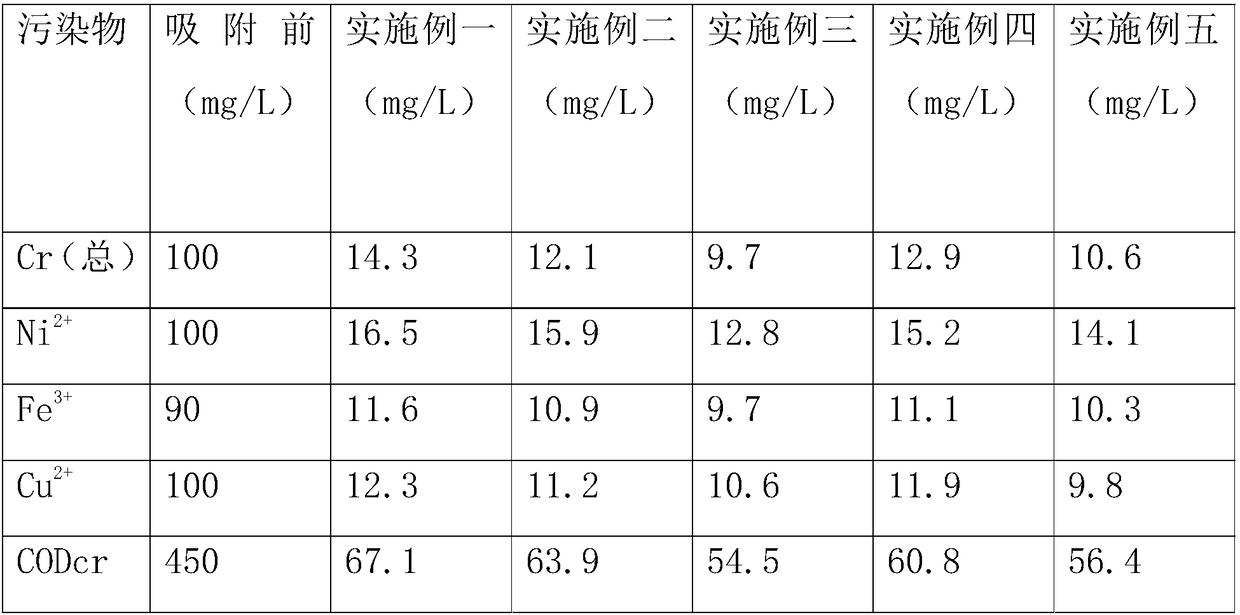

Examples

preparation example Construction

[0037] In the present embodiment, the preparation method of the high-temperature industrial wastewater treatment agent comprises the following steps:

[0038] (1) After mixing activated carbon, nano ferric oxide, lipase solution and tea polyphenols, adjust the pH of the mixture to 7.0, then place it in a shaker with a rotation speed of 150-155r / min, and treat 4- 5h;

[0039] (2) Add sodium humate and chitosan to the mixture obtained in step (1), after continuing to stir for 30-45min, add sepiolite powder, zeolite powder, medical stone powder, vermiculite, perlite, carboxymethyl Sodium starch starch and polyaluminum chloride are mixed and stirred for 1h-1.5h; the preparation method is simple and easy to operate, by first mixing lipase liquid with high temperature activity, tea polyphenols, activated carbon and nano ferric oxide, It is possible to introduce magnetic nano-ferric oxide into activated carbon, and at the same time introduce active groups on the surface of activated...

Embodiment 1

[0042] The high-temperature industrial wastewater treatment agent provided in this embodiment, the raw materials of the treatment agent include the following components in parts by weight: 20 parts of activated carbon, 10 parts of nano iron ferric oxide, 45 parts of lipase liquid, 5 parts of sepiolite powder, zeolite 5 parts of powder, 5 parts of medical stone powder, 5 parts of vermiculite, 5 parts of perlite, 10 parts of chitosan, 3 parts of sodium humate, 10 parts of sodium carboxymethyl starch, 8 parts of polyaluminum chloride, tea poly 0.5 parts of phenol;

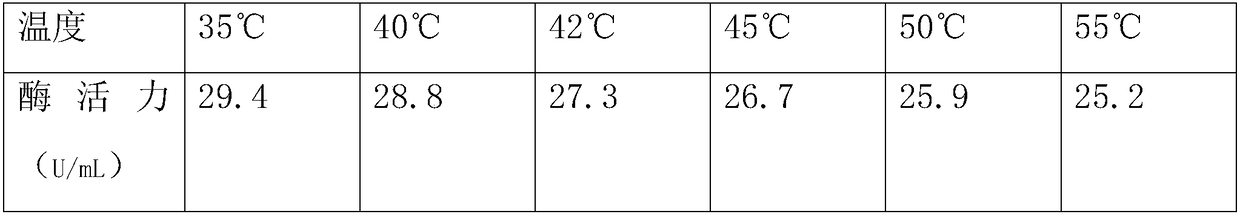

[0043] Wherein, the lipase liquid is the lipase liquid secreted by Pseudomonas stutzeri, Pseudomonas aeruginosa and Aspergillus niger inoculated in the culture medium at a ratio of 1:1:2 for mixed fermentation; The total inoculum of Monomonas, Pseudomonas aeruginosa and Aspergillus niger is 10% of the medium volume of fermentation culture; the culture conditions are: the pH of the medium is 7.0, the culture temperatur...

Embodiment 2

[0061] The high-temperature industrial wastewater treatment agent provided in this embodiment, the raw materials of the treatment agent include the following components in parts by weight: 22 parts of activated carbon, 11 parts of nanometer ferric oxide, 48 parts of lipase liquid, 7 parts of sepiolite powder, zeolite 6 parts of powder, 6 parts of medical stone powder, 7 parts of vermiculite, 6 parts of perlite, 11 parts of chitosan, 4 parts of sodium humate, 11 parts of sodium carboxymethyl starch, 9 parts of polyaluminum chloride, tea poly 0.6 parts of phenol;

[0062] Wherein, the lipase liquid is the lipase liquid secreted by Pseudomonas stutzeri, Pseudomonas aeruginosa and Aspergillus niger inoculated in the culture medium at a ratio of 1:1:2 for mixed fermentation; The total inoculum amount of Monomonas, Pseudomonas aeruginosa and Aspergillus niger is 9% of the medium volume of fermentation culture; the culture conditions are: the pH of the medium is 7.2, the culture temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com