Preparation method of Cu-Ce-La-SSZ-13 molecular sieve catalyst

A molecular sieve and catalyst technology, which is applied in the preparation of Cu-Ce-La-SSZ-13 molecular sieve catalyst and chabazite SSZ catalyst, can solve the problems of low water resistance and sulfur resistance, which need to be improved, and achieve sulfur resistance Improvement, excellent low-temperature catalytic activity, and the effect of increasing active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 6.2222g NaOH in 25mL deionized water, after the dissolution is complete, add 3.1877g NaAlO 2 , Stir continuously until the solution is completely dissolved and the solution becomes clear and transparent. Take another beaker, dissolve 7.1367g copper sulfate pentahydrate with 30mL deionized water, and place it in a constant temperature water bath at 25°C. After the dissolution is complete, 5.4111 g of tetraethylenepentamine is slowly added dropwise to the copper sulfate solution, and the beaker containing the tetraethylenepentamine liquid is rinsed with 5 mL of deionized water. Add 0.3040g Ce(NO) after Cu-TEPA complexation for 4h 3 ·6H 2 O and 0.3867g LaNO) 3 ·6H 2 O continued stirring for 1 h. After the complexation is completed, slowly add the template solution to the configured NaOH, NaAlO 2 solution, and rinse the beaker containing the template solution with 5mL deionized water. After stirring the mixed solution for 5-10 minutes, add 38.2000g of silica...

Embodiment 2

[0025] This example is basically the same as Example 1, the only difference is that the homogeneous hydrothermal reaction temperature is 140°C. After centrifugation, the obtained product has a small amount of impurity layered, most of which are consistent with the appearance of the product at 160°C.

Embodiment 3

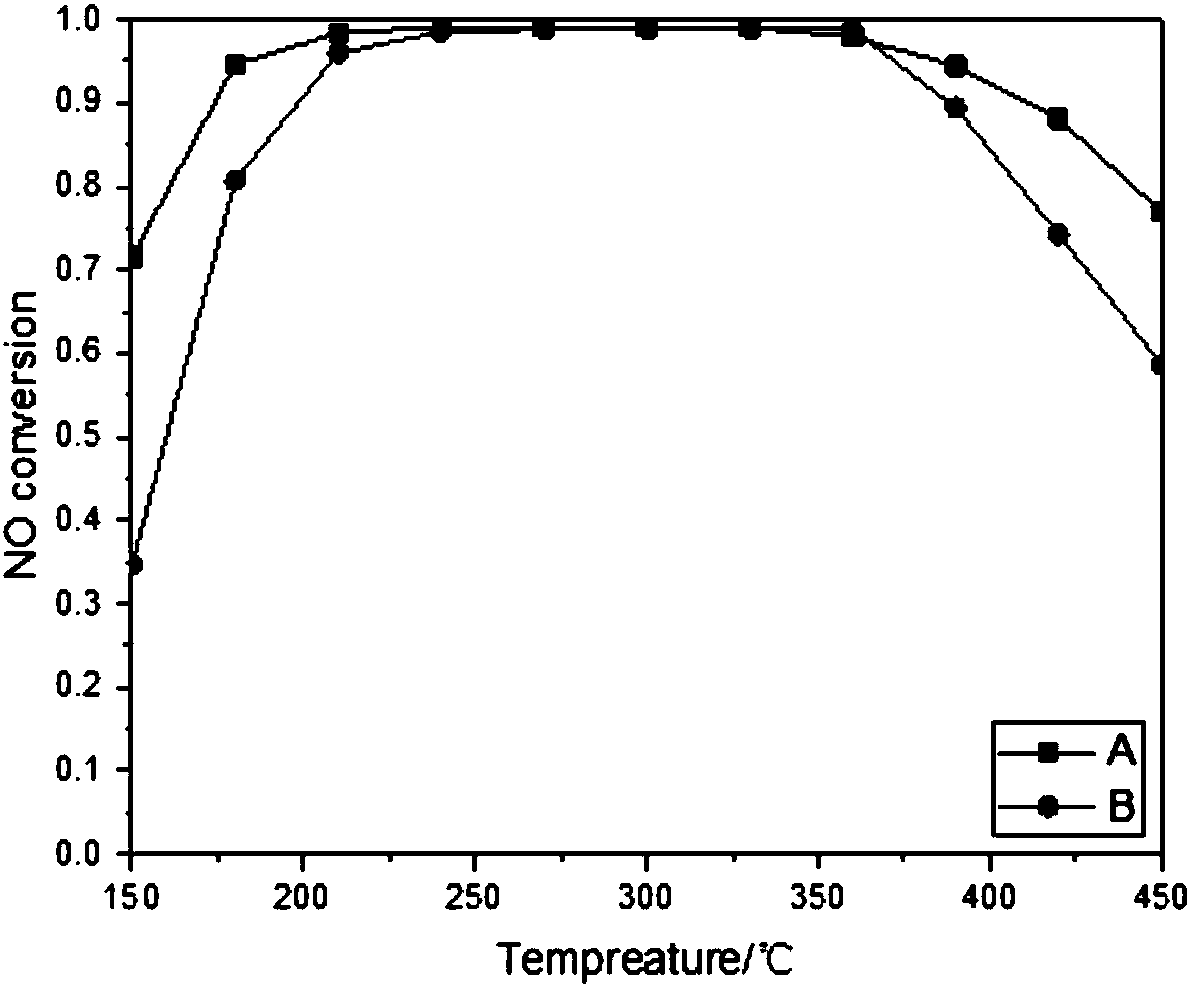

[0031] Test the denitration performance of Cu-Ce-La-SSZ-13 molecular sieve, the gas space velocity (GHSV) is 200000h -1 . The reactant gas composition is 1000ppm nitrogen oxides, 1000ppm NH 3 , 5% O 2 and the balance gas is N 2 . From figure 2It can be seen that the maximum catalytic activity of Cu-Ce-La-SSZ-13 molecular sieve synthesized by one step and Cu-Ce-SSZ-13 molecular sieve synthesized by ion exchange increases with the increase of temperature, and both reach more than 95% at 210 °C . The maximum catalytic activity of the one-step synthesized Cu-Ce-La-SSZ-13 molecular sieve was achieved at 240°C, while the maximum catalytic activity of the Cu-Ce-SSZ-13 molecular sieve synthesized by ion exchange was achieved at 270°C. It shows that the one-step synthesis of Cu-Ce-La-SSZ-13 expands the range of the optimal denitration temperature window, and further improves the denitration efficiency of the low temperature section and the high temperature section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com