Polyamide composite membrane and preparation method thereof

A composite membrane and polyamide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of ineffective membrane performance improvement, membrane performance degradation, and affecting the stability of the water-oil phase solution. Achieve the effects of thin functional layer, dense structure and increased crosslinking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A polyamide composite membrane, comprising a composite membrane body, the composite membrane body is a flat membrane, specifically including a non-woven fabric, a porous support layer and a polyamide layer arranged in sequence from bottom to top, and the polyamide layer is composed of polyamine solution It is prepared by interfacial polymerization reaction with polyacyl chloride solution, wherein the polyamine is a polyamine with a star molecular structure. The composite membrane body can also be designed as a non-woven fabric, a porous support layer and a polyamide layer arranged from the inside to the outside, specifically, it can be designed as a hollow fiber membrane or a tubular membrane to meet different needs.

[0047] The preparation process of the above-mentioned polyamide composite membrane is as follows:

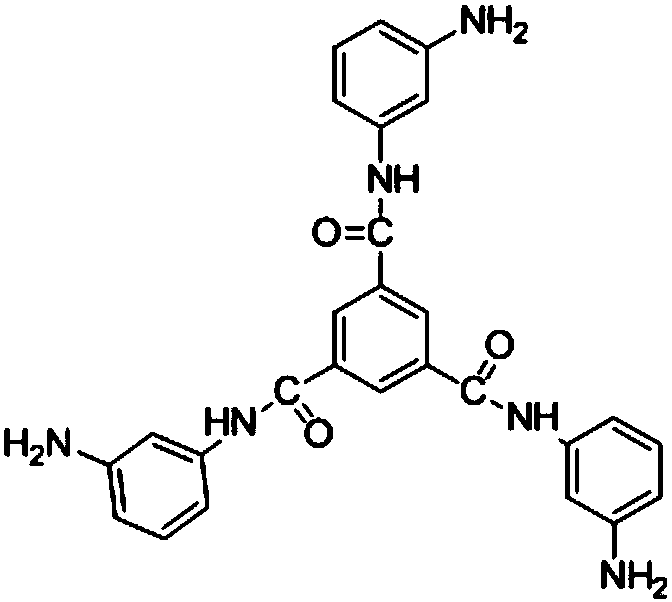

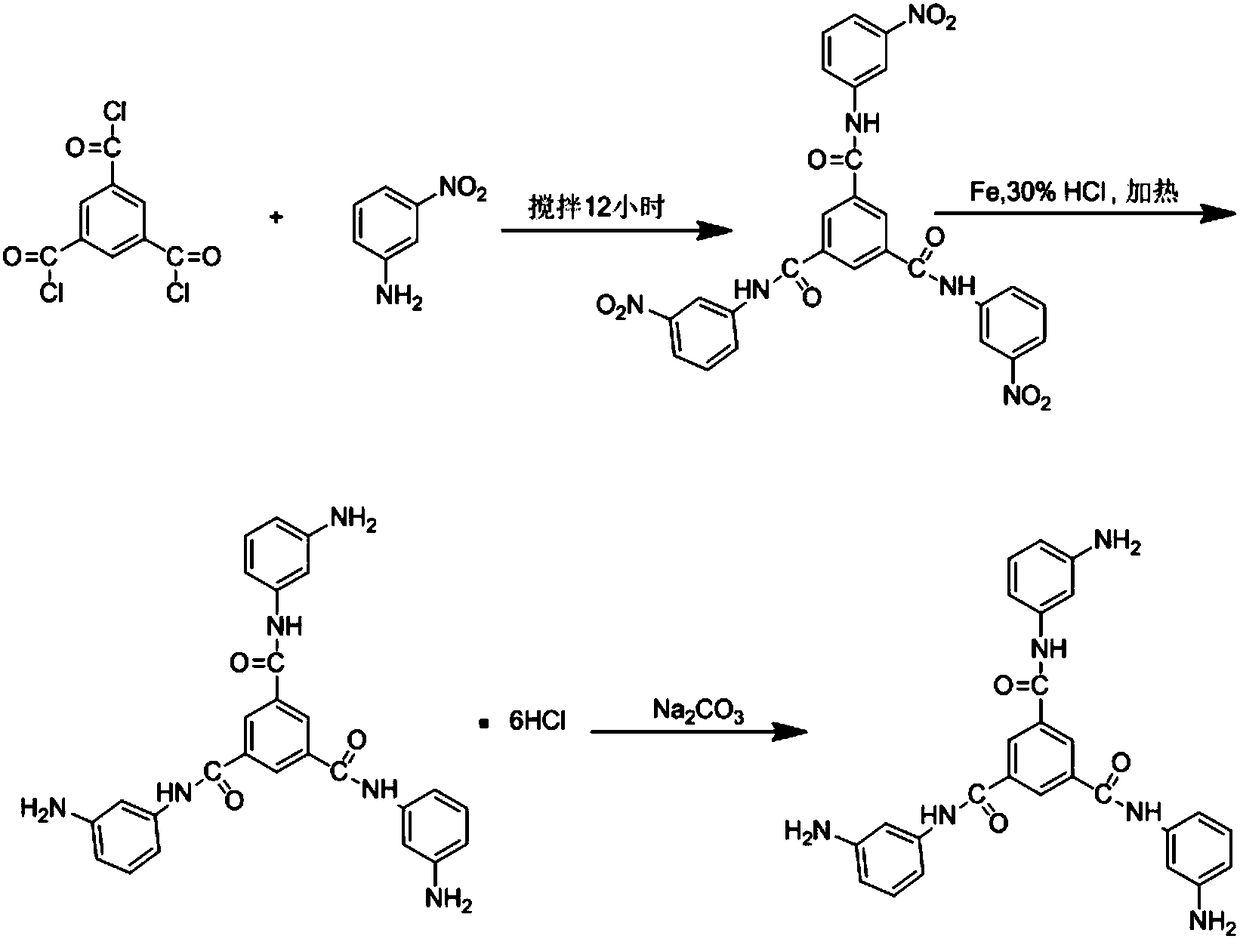

[0048] The first step, the preparation of polyamine solution, specifically: take trimesoyl-m-phenylenediamine 240g, triethylamine 88g, camphorsulfonic acid...

Embodiment 2

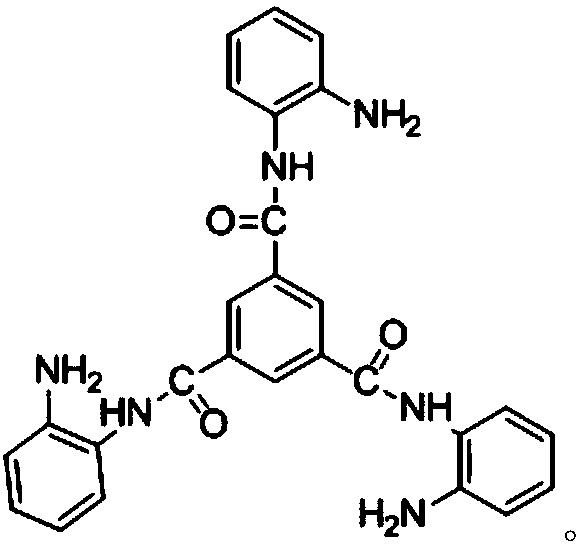

[0066] A kind of polyamide composite film, difference with embodiment 1 is: (1) the preparation of polyamine solution, specifically: take trimesoyl-o-phenylenediamine 240g, triethylamine 88g, camphorsulfonic acid 184g And sodium dodecylsulfonate 8g is dissolved in 7480g water, stirs to obtain polyamine solution; (2) trimesoyl-o-phenylenediamine is as follows:

[0067]

[0068] (3) The synthesis method of trimesoyl-o-phenylenediamine is similar to the examples, except that the reaction monomer is o-nitroaniline.

[0069] The chemical structure of the synthesized product analyzed by Fourier transform infrared spectrometer (FTIR) is similar to that of Example 1.

[0070] Take the diaphragm and test it on a cross-flow diaphragm testing platform. The test conditions are: sodium chloride aqueous solution 1500ppm, operating pressure 150psi, test temperature 25°C, and pH value 6.5-7.5. The results are shown in Table 1.

[0071] The cross-linking degree test of the functional layer...

Embodiment 3

[0074] A kind of polyamide composite film, difference with embodiment 1 is: (1) the preparation of polyamine solution, specifically: take trimesoyl-p-phenylenediamine 240g, triethylamine 88g, camphorsulfonic acid 184g And sodium dodecylsulfonate 8g is dissolved in 7480g water, stirs to obtain polyamine solution; (2) trimesoyl-p-phenylenediamine is as follows:

[0075]

[0076] (3) The synthesis method of trimesoyl-p-phenylenediamine is similar to that in the examples, except that the reaction monomer is p-nitroaniline.

[0077] The chemical structure of the synthesized product analyzed by Fourier transform infrared spectrometer (FTIR) is similar to that of Example 1.

[0078] Take the diaphragm and test it on a cross-flow diaphragm testing platform. The test conditions are: sodium chloride aqueous solution 1500ppm, operating pressure 150psi, test temperature 25°C, and pH value 6.5-7.5. The results are shown in Table 1.

[0079] The cross-linking degree test of the function...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com