Environment-friendly liquid level alarm system for papermaking clear-water basin

A technology of liquid level alarm and clear water pool, which is applied in liquid level control, control/regulation system, measuring device, etc., can solve the problems of lack of real-time monitoring of water quality in clear water pool, high cost, and affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

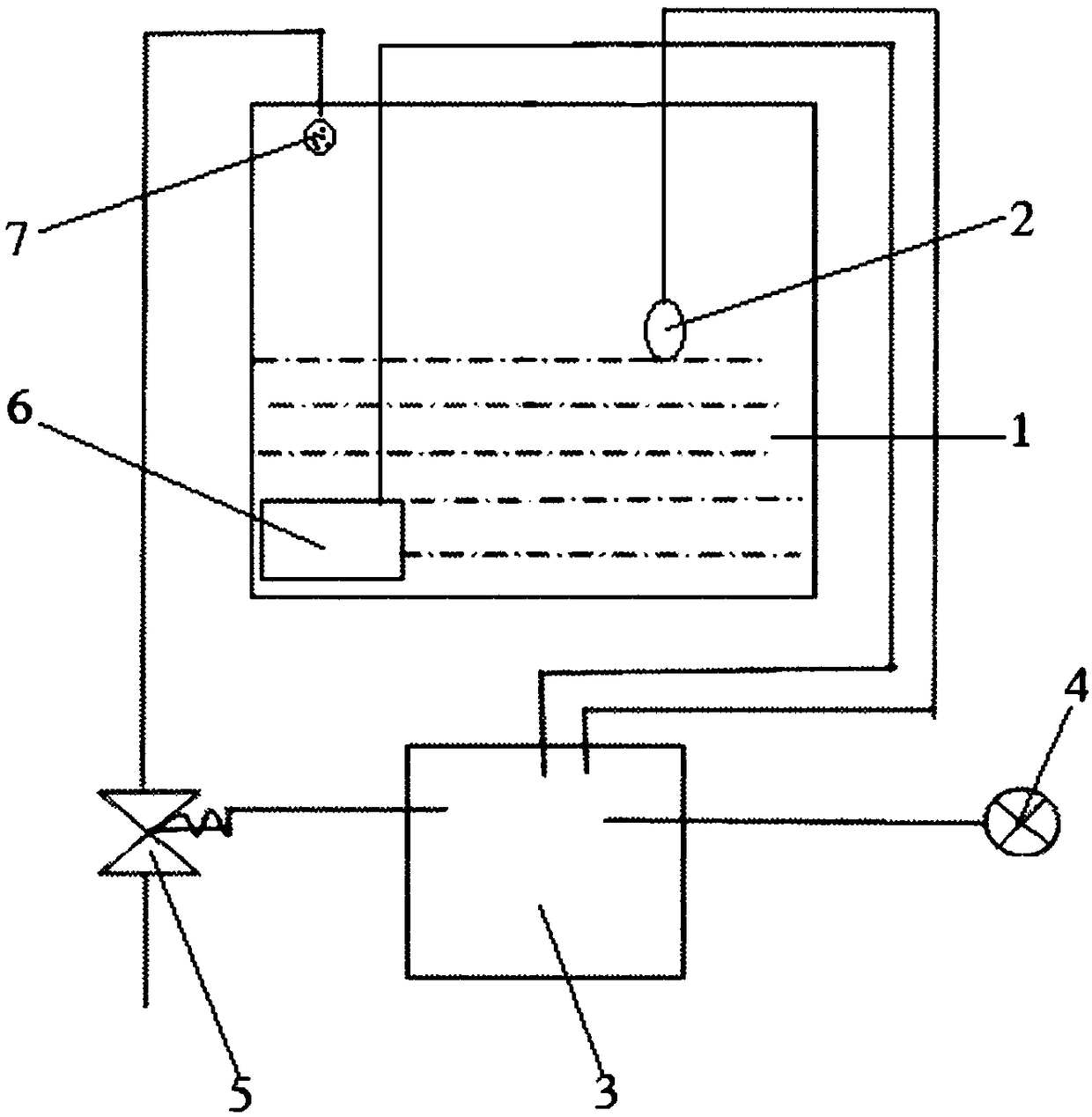

[0016] An environmentally friendly liquid level alarm system for papermaking clear water tanks, such as figure 1 As shown, it includes a float level controller, a control box 3, a pump 5, an alarm 4 and a water quality monitoring sensor 6, the float 2 of the float level controller is set on the liquid surface of the pool 1, and the water quality monitoring sensor 6 is set At the bottom of the pool, the float level controller and the water quality monitoring sensor are connected to the control box 3, the output end of the control box 3 is connected to the pump 5 and the alarm 4, the pump 5 is connected to the pool through a pipeline, and a filter screen 7 is set at the outlet end of the pipeline. The pump is driven by a motor, the pump adopts a clean water pump, and the motor adopts a three-phase asynchronous motor. The float 2 floats up and down with the liquid level. When the liquid level is low, the float level controller closes the circuit, and the control box 3 starts the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com