Three-dimensional shape monitoring device and method for greenhouse crops based on depth camera

A technology of depth camera and three-dimensional shape, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of not being able to fully obtain high-robust crop information, achieve reduction of labor costs, improvement of facility agronomy, and increase of crop yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and example.

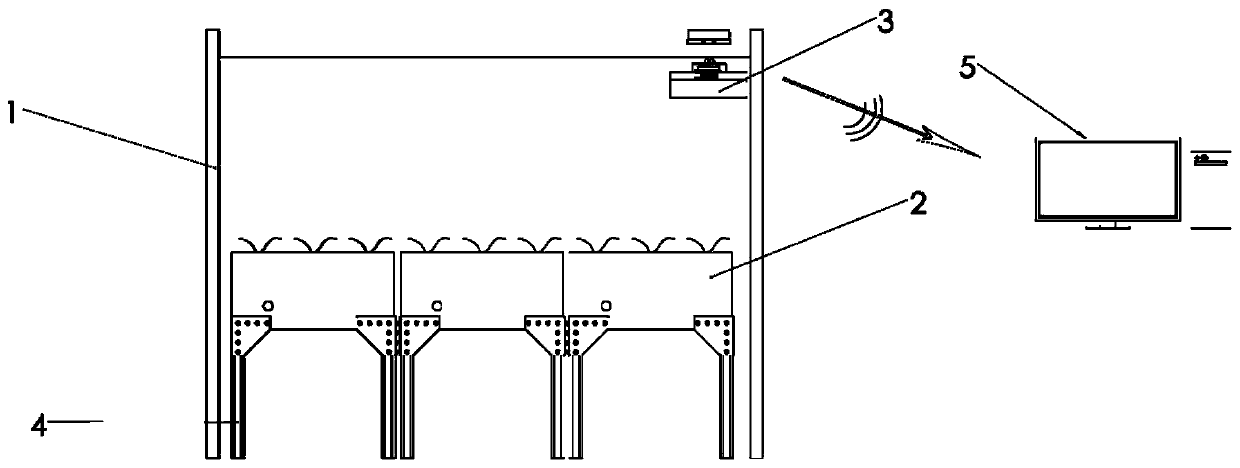

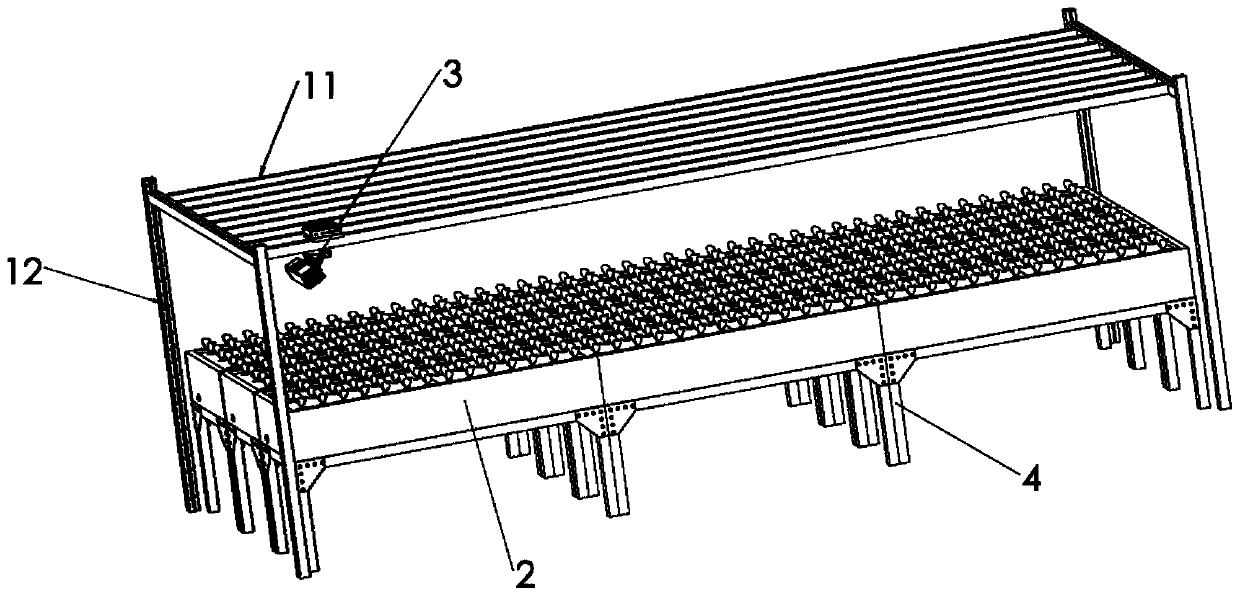

[0038] Such as figure 2 , image 3 , Figure 7 As shown, the present invention includes a monitoring mechanism support 1, a hydroponic device 2 with crops, a monitoring mechanism 3, a planting support 4 and a monitoring terminal 5; The hydroponic device 2 is installed on the planting support 4, and is located in the monitoring mechanism support 1. The monitoring mechanism support 1 is surrounded by a frame surrounded by rails 11, and the support 12 supports the frame. The frame is equidistant along the length direction. Tracks 11 are provided, and each track 11 is welded into a "□"-shaped track by two left and right channel steels, and there is a gap in the middle of the "□"-shaped track, and the monitoring mechanism 3 can move through its own moving mechanism 34. Moving along the "□" shaped track, moving directly above the crops of the hydroponic device 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com