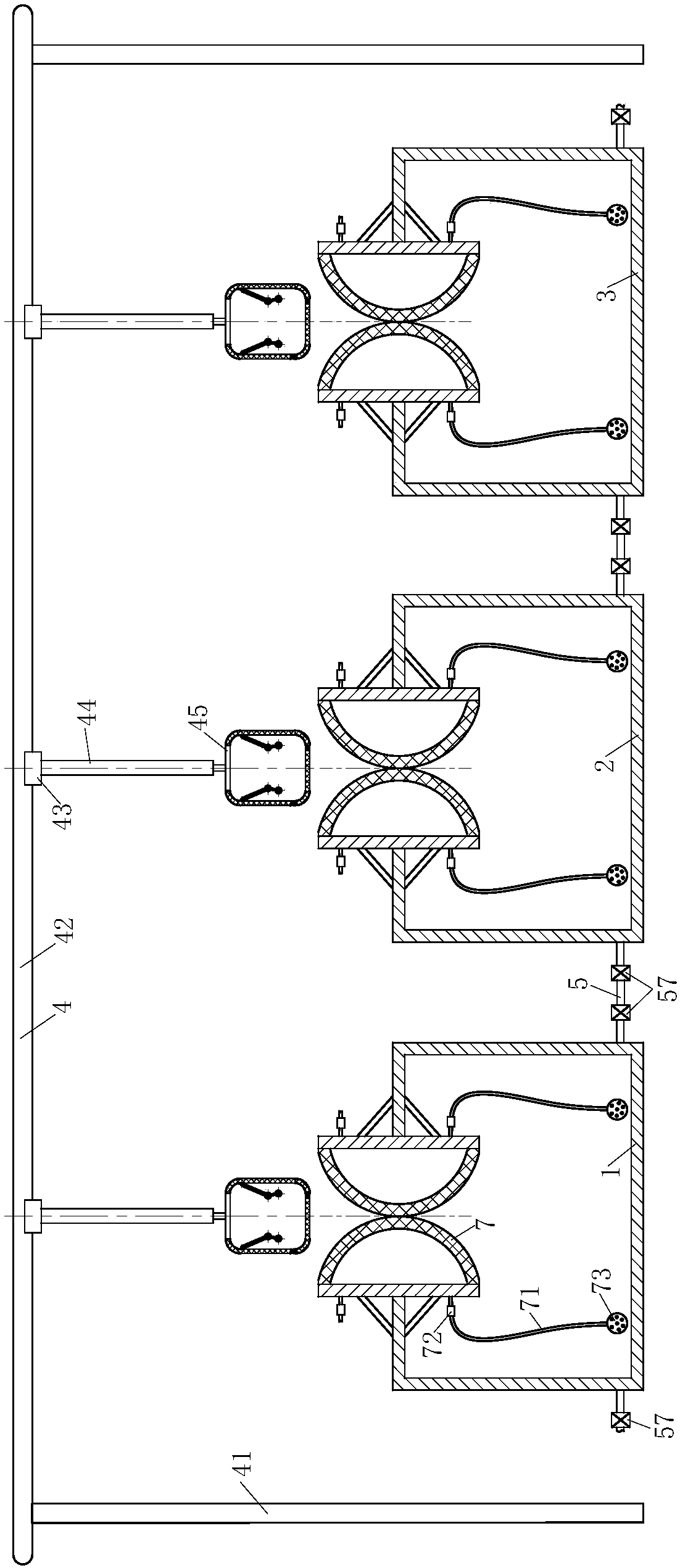

Soaking-extracting-method rose extract extracting system

An extraction system and technology of extraction method, applied in the field of extraction method of rose extract extraction system, can solve the problems of increasing the workload of separating impurities, being unable to adapt to large-scale processing, increasing the content of solvent impurities, and achieving the realization of assembly line operation, reducing The effect of small comprehensive extraction time and reduction of volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

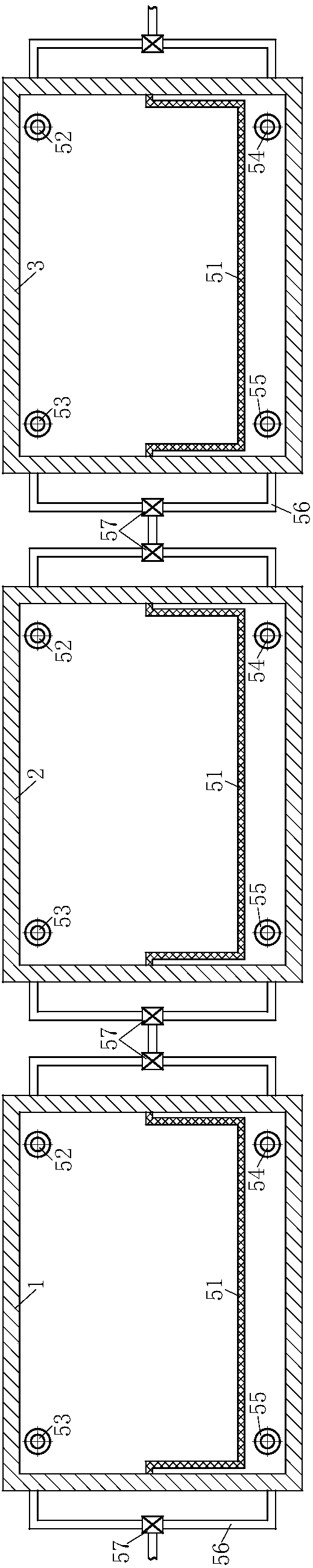

Method used

Image

Examples

Embodiment approach

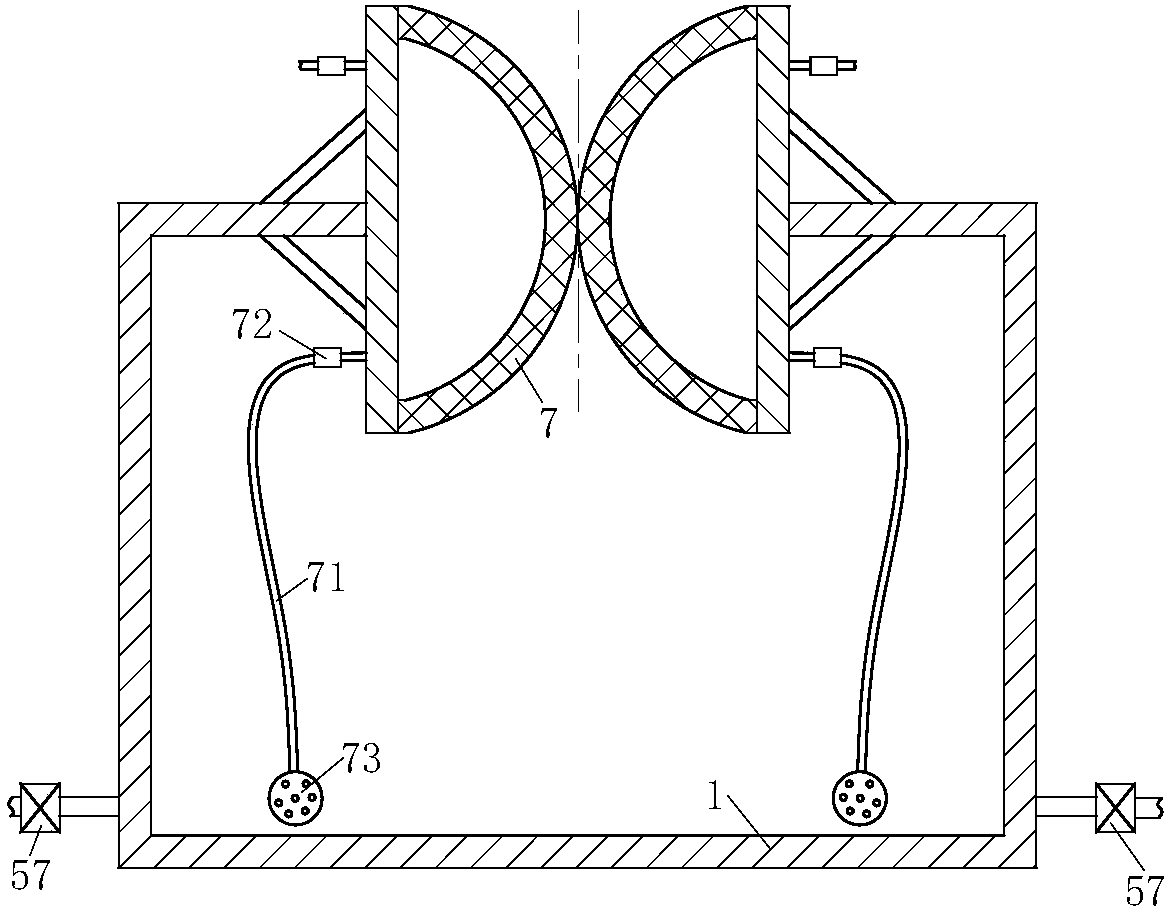

[0030] As an embodiment of the present invention, both sides of the annular airbag 7 are fixedly connected with a trachea 71; one end of the trachea 71 is provided with a check valve 72; 45 squeezes into the reaction box, squeezes the annular airbag 7 and blows air into the organic solvent through the trachea 71, utilizes the bubble disc 73 to generate a large number of bubbles, increases the fluidity of the organic solvent, and improves the efficiency of petal extraction.

[0031] As an embodiment of the present invention, the inner walls on both sides of the upper part of the material frame 45 are respectively rotatably connected to a baffle plate 454; one end of the baffle plate 454 is fixedly connected to the floating unit 455; the baffle plate 454 is used to close the material frame 45 is catchy, the petals can float on the surface of the organic solvent, the floating unit 455 floats and seals the entrance of the material frame 45 through the baffle 454, and when the teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com