Preparation method of environment-friendly micro-evaporative paint stripper

A paint stripper and environment-friendly technology, applied in the field of preparation of environment-friendly micro-evaporative paint strippers, can solve the problems of single removal mechanism of paint strippers, long paint stripping time of paint strippers, unreasonable composition of paint strippers, etc. problems, to achieve the effect of improving the wall-hanging performance and load-covering performance, increasing the flow resistance, and increasing the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

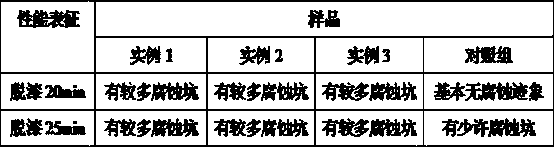

Examples

example 1

[0018] Take sodium carboxymethyl cellulose and grind it through a 200-mesh sieve to obtain sodium carboxymethyl cellulose powder. Add the sodium carboxymethyl cellulose powder to deionized water in a mass ratio of 1:8, stir and mix to obtain sodium carboxymethyl cellulose powder. Cellulose sodium solution, then according to the volume ratio of 1:10, add the mass fraction of 15% ferric chloride solution to the carboxymethyl cellulose sodium solution dropwise, after adding dropwise at room temperature for 25min, then stir and mix at 250r / min 2h, standing and aging for 6h, filtering to obtain a filter cake, and vacuum freeze-drying to obtain modified particles; in parts by weight, weigh 45 parts of formic acid, 25 parts of acetic acid, 45 parts of phenol, 3 parts of organic bentonite, and 1 part of ten Sodium dialkylbenzoate, 0.1 part of benzotriazole and 15 parts of modified particles were placed in an Erlenmeyer flask, stirred and mixed, heated in a water bath at 45°C for 25 min...

example 2

[0020] Take sodium carboxymethyl cellulose and grind it through a 200-mesh sieve to obtain sodium carboxymethyl cellulose powder. Add the sodium carboxymethyl cellulose powder to deionized water in a mass ratio of 1:8, stir and mix to obtain sodium carboxymethyl cellulose powder. Cellulose sodium solution, then according to the volume ratio of 1:10, add the mass fraction of 15% ferric chloride solution to the carboxymethyl cellulose sodium solution dropwise, after adding dropwise at room temperature for 27min, then stir and mix at 275r / min 2h, standing and aging for 7h, filtering to obtain a filter cake, and vacuum freeze-drying to obtain modified particles; in parts by weight, weigh 47 parts of formic acid, 27 parts of acetic acid, 47 parts of phenol, 4 parts of organic bentonite, 2 parts of ten Sodium dialkylbenzoate, 0.8 parts of benzotriazole and 17 parts of modified particles were placed in an Erlenmeyer flask, stirred and mixed, heated in a water bath at 47°C for 27 minut...

example 3

[0022] Take sodium carboxymethyl cellulose and grind it through a 200-mesh sieve to obtain sodium carboxymethyl cellulose powder. Add the sodium carboxymethyl cellulose powder to deionized water in a mass ratio of 1:8, stir and mix to obtain sodium carboxymethyl cellulose powder. Cellulose sodium solution, then according to the volume ratio of 1:10, add the mass fraction of 15% ferric chloride solution dropwise to the carboxymethylcellulose sodium solution, add dropwise at room temperature for 30min, then stir and mix at 300r / min 3h, standing and aging for 8h, filtering to obtain a filter cake, and vacuum freeze-drying to obtain modified particles; in parts by weight, weigh 50 parts of formic acid, 30 parts of acetic acid, 50 parts of phenol, 5 parts of organic bentonite, 2 parts of ten Sodium dialkylbenzoate, 1.2 parts of benzotriazole and 20 parts of modified particles were placed in an Erlenmeyer flask, stirred and mixed, heated in a water bath at 50°C for 30 minutes, ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com