3D printing impurity cleaning method based on image collection

A 3D printing and image acquisition technology, applied in the field of 3D printing, can solve problems such as insufficient processing efficiency and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

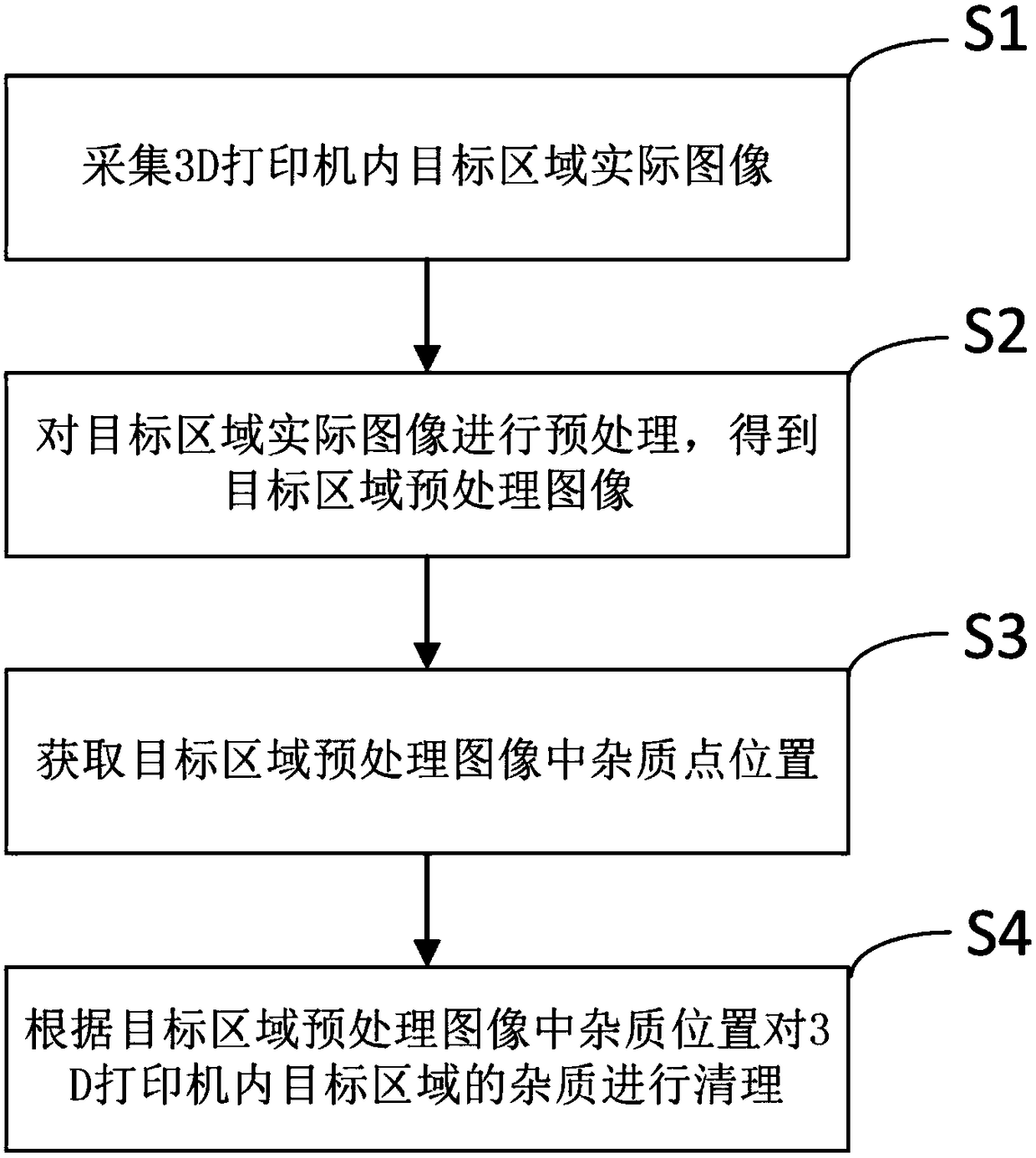

[0025] refer to figure 1 , a method for cleaning impurities in 3D printing based on image acquisition proposed by the present invention, comprising:

[0026] Step S1, collecting the actual image of the target area in the 3D printer. Before collecting the actual image of the target area in the 3D printer, it also includes: judging whether the 3D printer has completed the current printing task, and when the judgment result is yes, collecting the actual image of the target area in the 3D printer, Or, it is judged whether the foreign matter cleaning instruction is received, and when the judgment result is yes, the actual image of the target area in the 3D printer is collected.

[0027] In the specific solution, after the 3D printer finishes the current printing task, the actual image of the target area in the 3D printer can be collected, and the impurity cleaning process starts. Further, after receiving the cleaning instruction from the user, the impurity cleaning process starts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com