PLC (programmable logic controller)-based control system for vertical lathe

A control system and technology for vertical lathes, applied in the field of lathe control, can solve problems such as difficulty in troubleshooting control problems, and achieve the effects of good applicability and practicability, simplified procedures, and intelligent work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

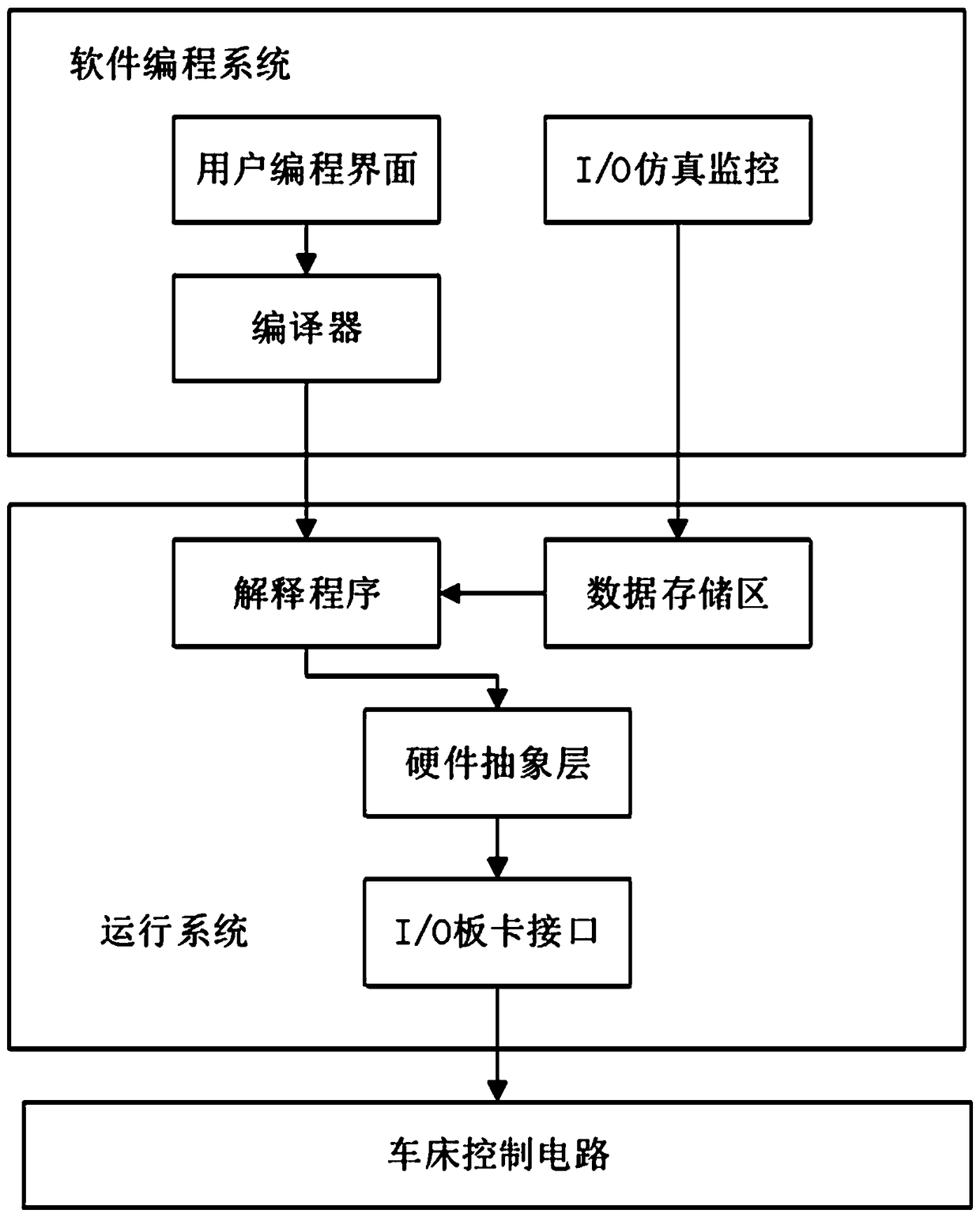

[0019] Such as figure 1 , The soft PLC system is an improvement to the traditional PLC system. Generally, the soft PLC system consists of two parts, one is the software programming part, and the other is the operating system part. The software programming system includes a user editing interface, a compiler, and an I / O simulation monitoring interface. The user programming interface is the final interface for users, providing users with programming methods and programming tools. The compiler compiles the PLC program written by the user into a conversion from the ladder diagram type to the instruction table, and the instruction table is easier to execute. The I / O simulation monitoring interface realizes the visual monitoring of the input and output data of the lathe.

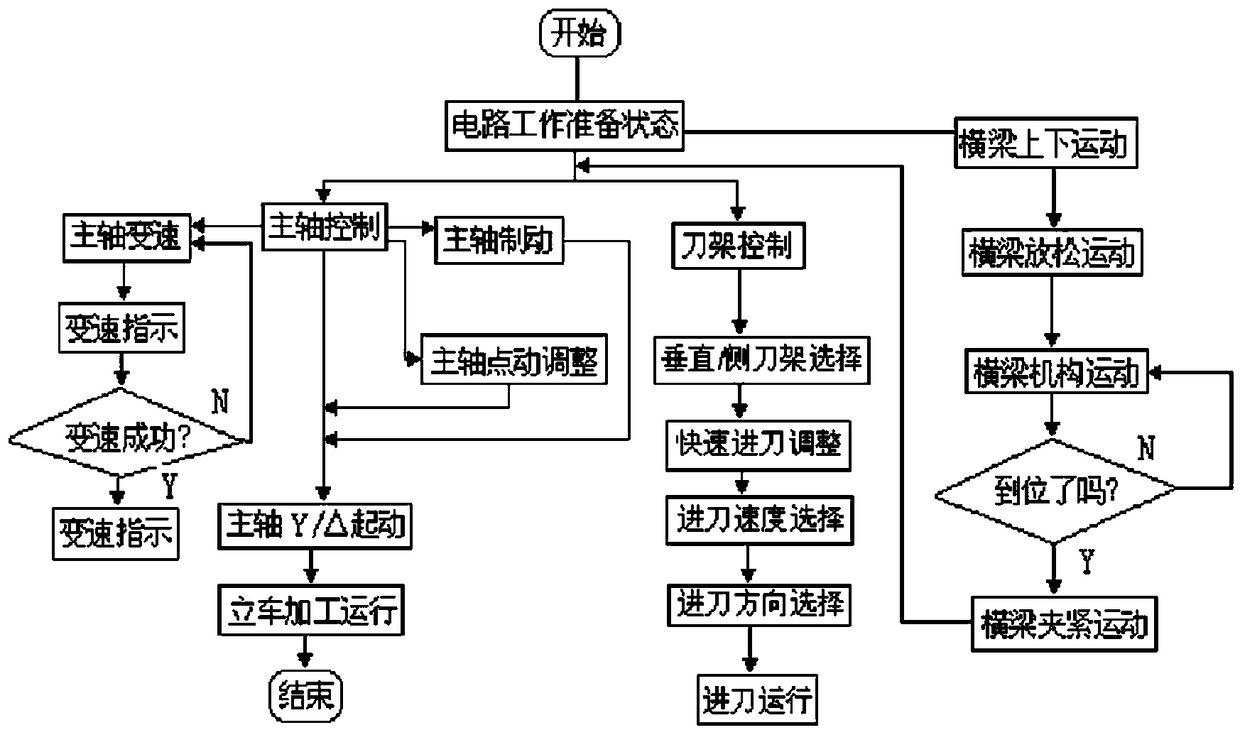

[0020] Such as figure 2 , In the C5116A vertical machine tool system, it is necessary to control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com