Pre-judgment method for internal microbattery reaction voltage interval of Li-ion battery

A lithium-ion battery and voltage range technology, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as uneven reaction strength, weak micro-battery reaction strength, and complex battery reaction, so as to improve detection efficiency and application Remarkable effect and shortened detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for predicting the reaction voltage interval of a micro-battery inside a lithium-ion battery, the implementation steps are as follows:

[0030] (1) Select the ternary mixed lithium iron phosphate positive electrode system (ternary: lithium iron phosphate = 8:2) battery for testing. First, use 0.2C to discharge the battery to 2.5V, set the sleep time to 3 hours, Used to eliminate discharge polarization.

[0031] (2) After dormancy, charge the battery. First, use 0.1C constant current charging for 30 minutes. Sleep time was set to 3 hours. After the dormancy is completed, repeat the constant current-sleep mode, and charge the battery intermittently to 4.2V.

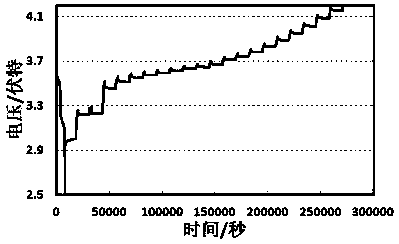

[0032] (3) Data collection and analysis, record the voltage and time data during the charging process in step (2), use the voltage data to plot the time data, the voltage is the vertical axis, and the time is the horizontal axis; figure 1 shown.

[0033] Use this method to charge the battery, and plot th...

Embodiment 2

[0035] A method for predicting the reaction voltage interval of a micro-battery inside a lithium-ion battery, the implementation steps are as follows:

[0036] (1) Select the ternary mixed lithium iron phosphate positive electrode system (ternary: lithium iron phosphate = 5:5) battery for testing. First, use 0.2C to discharge the battery to 2.5V, set the sleep time to 3 hours, Used to eliminate discharge polarization.

[0037] (2) After dormancy, charge the battery. First, use 0.1C constant current charging for 30 minutes. Sleep time was set to 3 hours. After the dormancy is completed, repeat the constant current-sleep mode, and charge the battery intermittently to 4.2V.

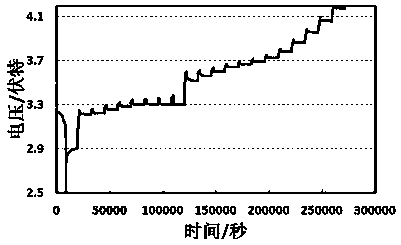

[0038] (3) Data collection and analysis, voltage vs. time plotting; such as figure 2 shown.

[0039] Use this method to charge the battery, and plot the voltage against time, such as figure 2 As shown, at 120,000 seconds, the voltage changed greatly in a short period of time, from 3.3V to 3.6V. The ap...

Embodiment 3

[0041] A method for predicting the reaction voltage interval of a micro-battery inside a lithium-ion battery, the implementation steps are as follows:

[0042] (1) Select the ternary mixed lithium iron phosphate positive electrode system (ternary: lithium iron phosphate = 2:8) battery for testing. First, use 0.2C to discharge the battery to 2.5V, set the sleep time to 3 hours, Used to eliminate discharge polarization.

[0043] (2) After sleep, charge the battery. First, use 0.1C constant current charging for 30 minutes; set the sleep time to 3 hours. After the dormancy is completed, repeat the constant current-sleep mode, and charge the battery intermittently to 4.2V.

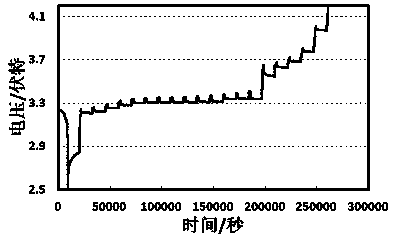

[0044] (3) Data collection and analysis, voltage vs. time plotting; such as image 3 shown.

[0045] Use this method to charge the battery, and plot the voltage against time, such as image 3 As shown, at 200,000 seconds, the voltage changed greatly in a short period of time, from 3.35V to 3.65V. The appear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com