Method for improving measuring accuracy of polarization performance of Y waveguide device

A waveguide device, accurate technology, applied in the field of polarization optical device measurement, can solve the problem of chip extinction ratio measurement error, not eliminating measurement error and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

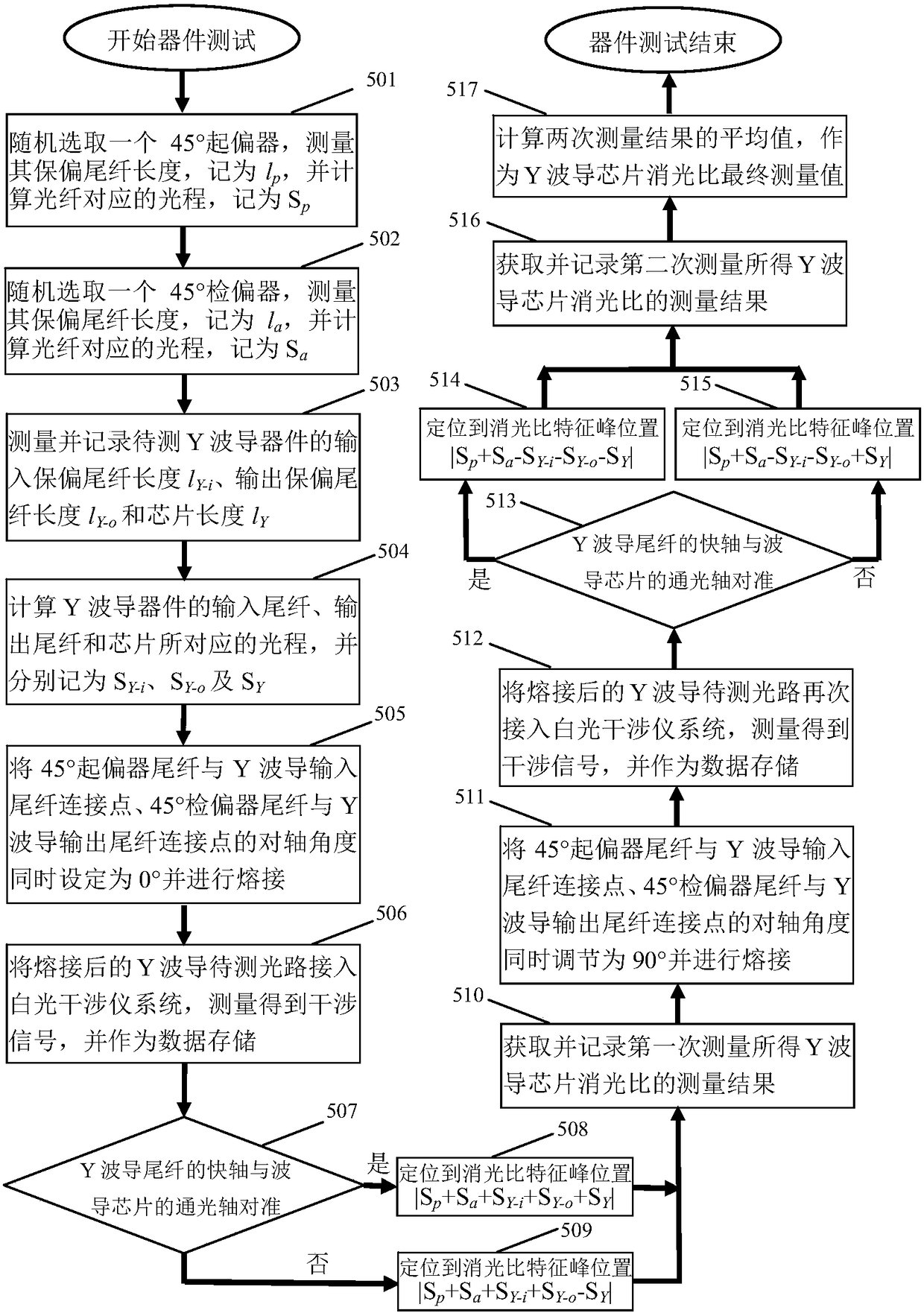

[0055] The specific embodiment one is a method for measuring the extinction ratio of a Y waveguide device chip, and the specific steps are:

[0056] (1) measure the length of the polarization-maintaining pigtail 202 of the randomly selected 45° polarizer 201, denoted as l p , and calculate the optical path corresponding to the fiber, denoted as S p = l p ×Δn b (Δn b is the linear birefringence of the polarization-maintaining pigtail);

[0057] (2) measure the length of the polarization-maintaining pigtail 208 of the randomly selected 45° analyzer 209, denoted as 1 a , and calculate the optical path corresponding to the fiber, denoted as S a = l a ×Δn b ;

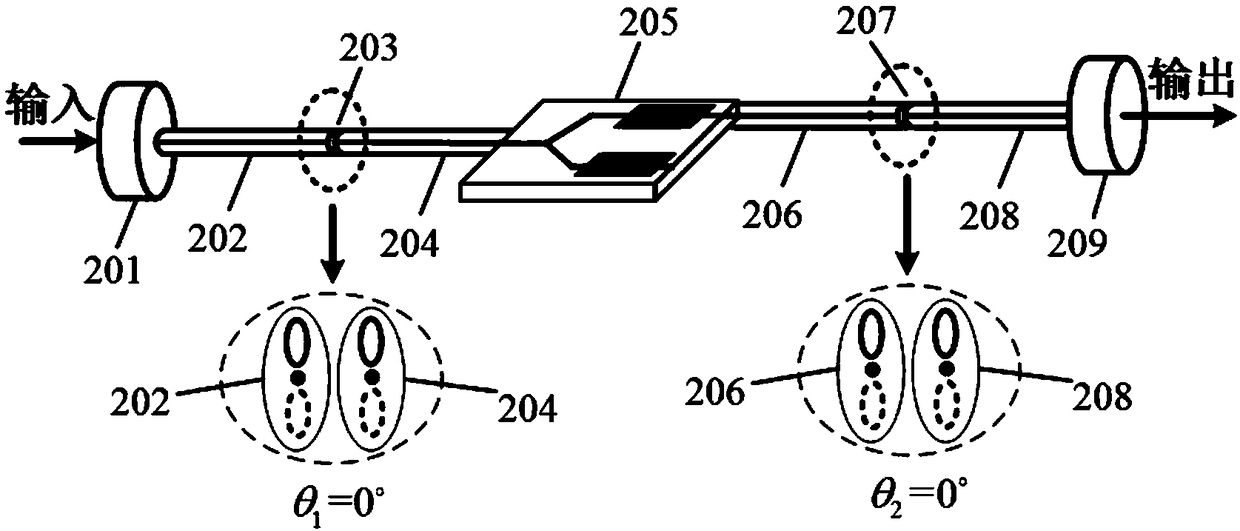

[0058] (3) measure and record the input pigtail 204 length l of the Y waveguide device to be tested Y-i , output pigtail 206 length l Y-o , and chip 205 length l Y ;

[0059] (4) Calculate the optical path corresponding to the input pigtail 204, the output pigtail 206, and the chip 205 of the Y waveguide device, ...

specific Embodiment approach 2

[0071] The second specific embodiment is a method for measuring the extinction ratio of a Y waveguide device chip, and the specific steps are:

[0072] (1) measure the length of the polarization-maintaining pigtail 202 of the randomly selected 45° polarizer 201, denoted as l p , and calculate the optical path corresponding to the fiber, denoted as S p = l p ×Δn b (Δn b is the linear birefringence of the polarization-maintaining pigtail);

[0073] (2) measure the length of the polarization-maintaining pigtail 208 of the randomly selected 45° analyzer 209, denoted as 1 a , and calculate the optical path corresponding to the fiber, denoted as S a = l a ×Δn b ;

[0074] (3) measure and record the input pigtail 204 length l of the Y waveguide device to be tested Y-i , output pigtail 206 length l Y-o , and chip 205 length l Y ;

[0075] (4) Calculate the optical path corresponding to the input pigtail 204, the output pigtail 206, and the chip 205 of the Y waveguide devic...

specific Embodiment approach 3

[0087] Specific embodiment three, on the basis of the above-mentioned first or second embodiment, the lengths of the polarization-maintaining pigtails 202 and 208 of the 45° polarizer and the 45° analyzer should meet the requirements of l as far as possible. p ≠l a , and require l p +l Y-i ≠ l a +l Y-o , in order to accurately judge and identify the meaning and position of each characteristic interference peak in the measurement interference signal.

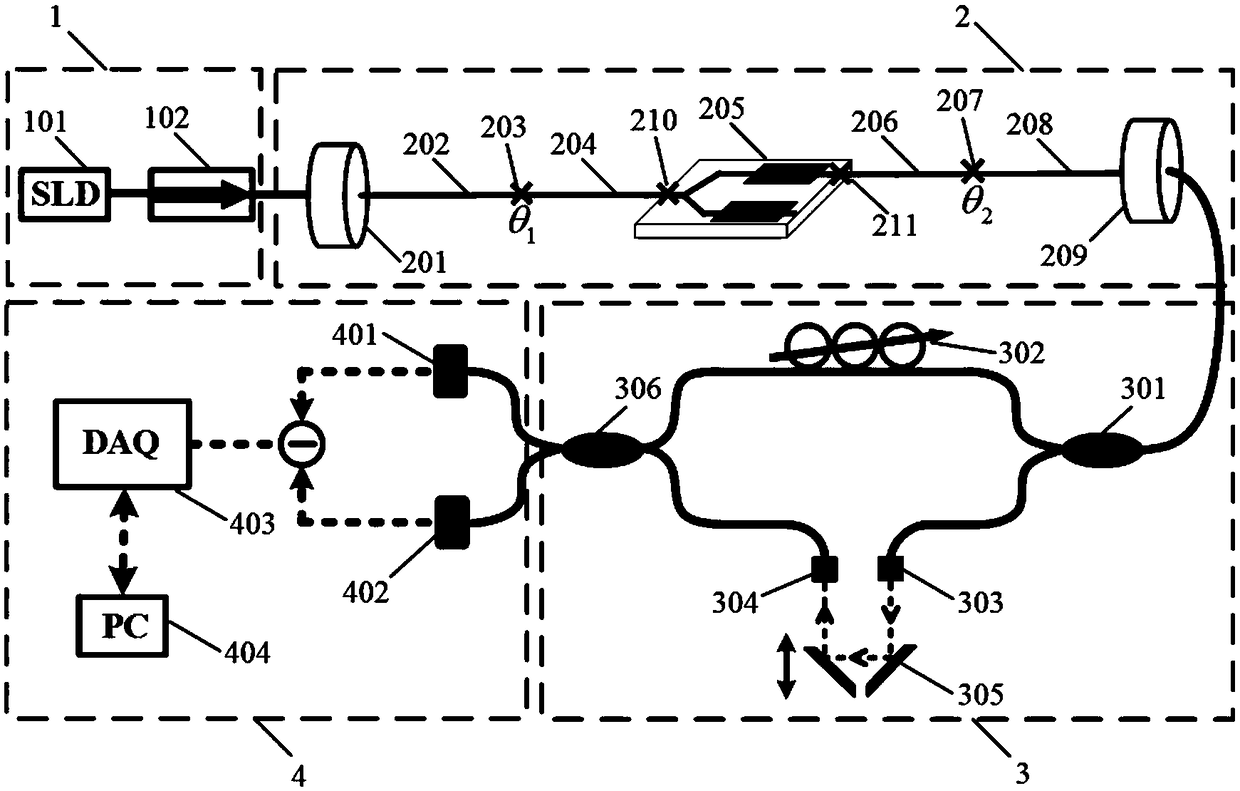

[0088] The polarization performance measurement device of Y waveguide device based on the principle of white light interference is attached figure 2 shown. After the wide-spectrum light source emitted by the light source module 1 passes through the Y-waveguide optical fiber optical path module 2 to be tested, the optical signal with the polarization characteristic of the Y-waveguide enters the scanning Mach-Zehnder interferometer module 3, and the interference signal finally reaches the signal detection and The data proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com