Efficient natural gas boiler with low-nitrogen emission

A technology for natural gas and nitrogen emissions, applied in the direction of reducing greenhouse gases, climate sustainability, and transportation of non-flammable liquids/gases. The problems of high equipment investment and operating costs can achieve the effect of reducing the heat exchange area and the volume of the boiler body, compact structure, and convenient equipment maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

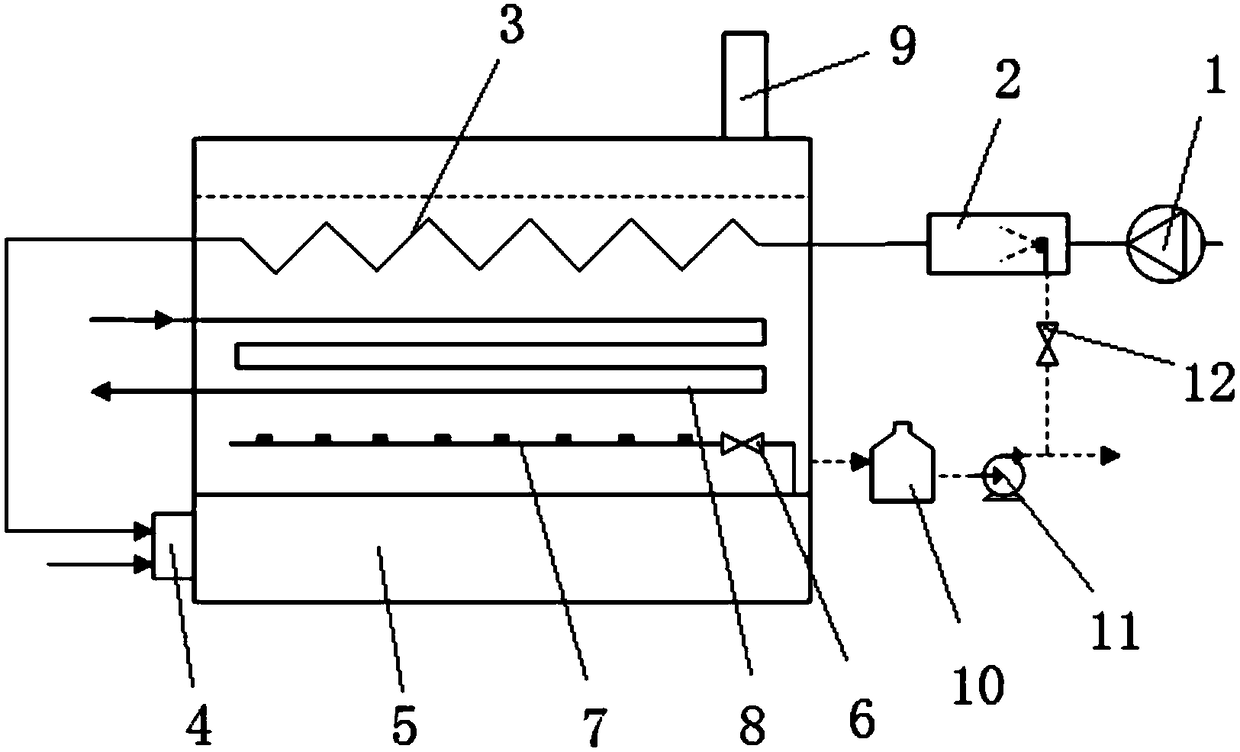

[0048] Such as figure 1 As shown, a low-nitrogen emission high-efficiency natural gas boiler, the gas boiler body adopts a horizontal structure, the combustion chamber 5 is arranged at the bottom of the boiler body, and the burner 4 is connected to the front end of the boiler body. The combustion-supporting air at the inlet of the blower 1 is introduced from the outdoor environment, and the outlet of the blower 1 is connected with the air inlet of the spray chamber 2. The front end of the spray chamber 2 is arranged with a pressure atomizing nozzle to spray atomized water droplets into the combustion-supporting air. The water-containing air discharged from the spray chamber 2 enters the inlet of the evaporation heat recovery tube bundle 3, and the outlet of the evaporation heat recovery tube bundle 3 communicates with the combustion air inlet of the burner 4.

[0049] Provide natural gas to the fuel inlet of the burner 4. The high-temperature flue gas generated by combustion e...

Embodiment 2

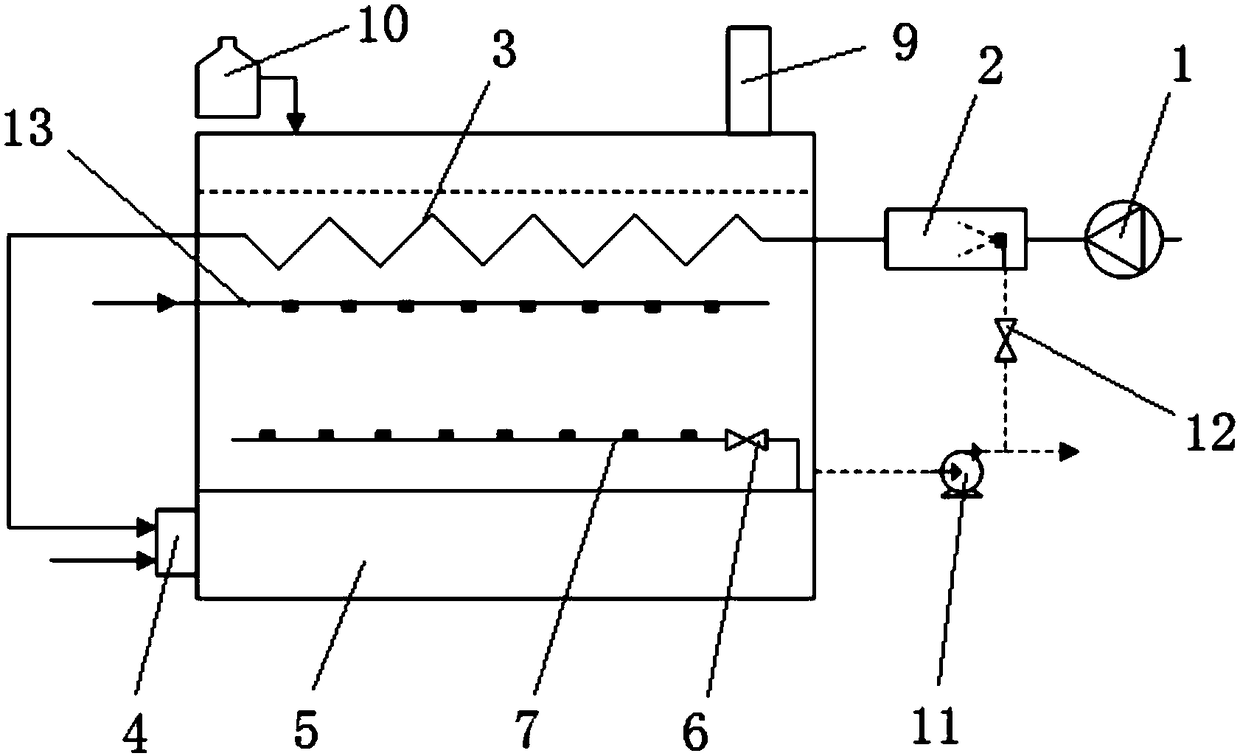

[0052] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment is that the heat exchange tube bundle and the heat medium water are eliminated, and the heating return water is directly sprayed into the upper part of the boiler body through the water distribution pipeline 13, and is directly connected with the high-temperature flue gas injected from bottom to top. The contact is heated, and the heated heating return water is discharged from the drain port and divided into two paths after being pressurized by the booster pump: one path is connected to the water atomization device at the front end of the spray chamber 2 after the flow is adjusted by the regulating valve 12; the other path is connected to The heating pipes are used as heating water. The water treatment device 10 is connected with the boiler body to adjust the pH value of the heating water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com