Coloring dye and aluminum alloy die casting brown coloring method

A technology for aluminum alloys and die-casting parts, which is applied in the field of coloring dyes and brown coloring of aluminum alloy die-casting parts, which can solve the problems of single coloring and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An embodiment of the present invention provides a colored dye, the colored dye includes: acid red, acid black and glacial acetic acid, wherein the concentration of acid red is 4-12g / L, and the concentration of acid black is 0.2-2.5g / L, The concentration of the glacial acetic acid is 0.1-5g / L. The coloring dye is suitable for coloring high-silicon aluminum alloy die-castings, wherein the high-silicon aluminum alloy die-casting refers to an aluminum alloy die-casting with a silicon content greater than 10%.

[0033] Because the molecular weights of acid red, acid black and glacial acetic acid in the colored dye of the present invention are all less than 1000, according to Dalton's empirical table, the molecular weight is 1000, and the corresponding aperture is 0.001 μm. filter membrane, and the colored dye can pass through the filter membrane smoothly, which proves that the colored dye is smaller than 1nm.

[0034] The coloring dyes provided by the embodiments of the pre...

Embodiment 2

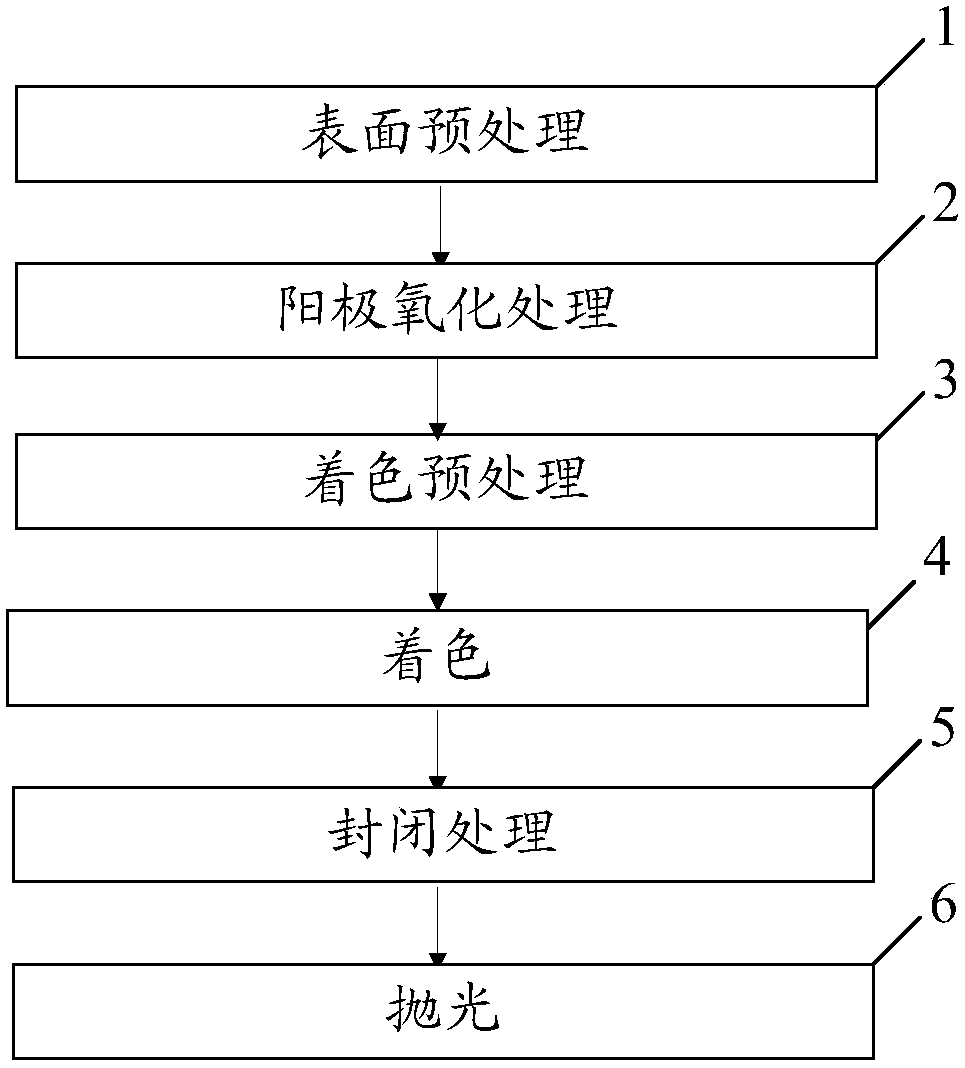

[0036] An embodiment of the present invention provides a brown coloring method for aluminum alloy die-castings, which is suitable for coloring high-silicon aluminum alloy die-castings, wherein high-silicon aluminum alloy die-castings refer to aluminum alloy die-castings with a silicon content greater than 10%. combine figure 1 , the method includes:

[0037] Step 1: Surface pretreatment, including:

[0038] Removal of residual oil stains on aluminum alloy die castings; specifically, chemical methods such as acid or lye cleaning can be used to remove residual oil stains on aluminum alloy die castings.

[0039] The surface of the aluminum alloy die casting is polished; specifically, the surface of the aluminum alloy die casting can be polished by mechanical polishing or chemical polishing.

[0040] Washed aluminum alloy die castings;

[0041] Soak the aluminum alloy die casting in concentrated nitric acid for 5-10 minutes to obtain an aluminum alloy die casting covered with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com