New process for producing D-tryptophan by chemical method and enzymic method

A technology of tryptophan and chemical method, which is applied in the new process field of producing D-tryptophan by chemical method and enzymatic method, can solve the problems of non-recycled by-products, unfavorable safety and environmental protection, low production efficiency, etc. Short route, simple production process, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

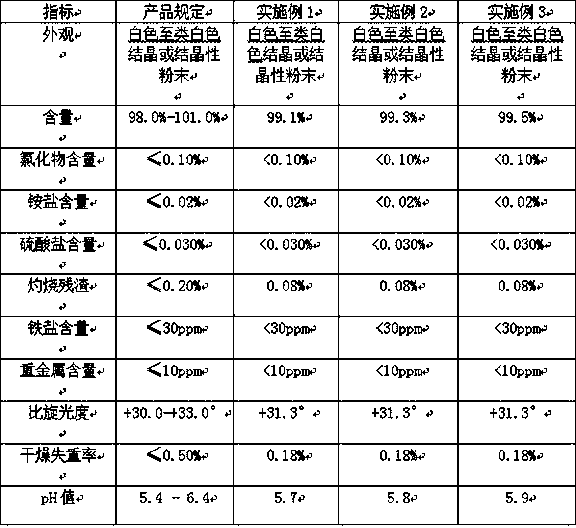

Examples

Embodiment 1

[0021] A new process of chemical and enzymatic production of D-tryptophan, including racemization, resolution, acetyl-DL-tryptophan refining, hydrolysis, D-tryptophan hydrochloride refining, decomplexation and mother liquor The processing step is to complete the synthesis process; the specific steps are as follows:

[0022] (1) Racemization: Put 107kg L-tryptophan, 428kg water, 214kg acetic anhydride and 53.5kg sodium hydroxide into the racemization reaction kettle. When the raw materials are added dropwise, the temperature is controlled below 50°C. Insulate and react at 45°C for 5 hours, then cool to below 40°C, adjust the pH value in the reaction kettle with hydrochloric acid, cool to below 30°C, centrifuge to obtain the filter cake as acetyl-DL-tryptophan, and send the mother liquor after racemization to To water treatment to be recycled;

[0023] (2) Splitting: Add 128kg of acetyl-DL-tryptophan prepared in step (1), 432kg of water and 54kg of sodium hydroxide to the split...

Embodiment 2

[0030] A new process of chemical and enzymatic production of D-tryptophan, including racemization, resolution, acetyl-DL-tryptophan refining, hydrolysis, D-tryptophan hydrochloride refining, decomplexation and mother liquor The processing step is to complete the synthesis process; the specific steps are as follows:

[0031] (1) Racemization: Put 533kgL-tryptophan, 2132kg water, 1066kg acetic anhydride and 266.5kg sodium hydroxide into the racemization reaction kettle. When the raw materials are added dropwise, the temperature is controlled below 50°C. Insulate and react at 45°C for 5 hours, then cool to below 40°C, adjust the pH value in the reaction kettle with hydrochloric acid, cool to below 30°C, centrifuge to obtain the filter cake as acetyl-DL-tryptophan, and send the mother liquor after racemization to To water treatment to be recycled;

[0032] (2) Splitting: add 640kg of acetyl-DL-tryptophan prepared in step (1), 2560kg of water and 320kg of sodium hydroxide to the s...

Embodiment 3

[0039] A new process of chemical and enzymatic production of D-tryptophan, including racemization, resolution, acetyl-DL-tryptophan refining, hydrolysis, D-tryptophan hydrochloride refining, decomplexation and mother liquor The processing step is to complete the synthesis process; the specific steps are as follows:

[0040] (1) Racemization: Put 320kgL-tryptophan, 1280kg water, 640kg acetic anhydride and 160kg sodium hydroxide into the racemization reaction kettle. Insulate and react at ℃ for 5 hours, then cool to below 40℃, adjust the pH value in the reaction kettle with hydrochloric acid, cool to below 30℃, centrifuge to obtain the filter cake as acetyl-DL-tryptophan, and send the mother liquor after racemization to Water treatment to be recycled;

[0041] (2) Splitting: Add 384kg of acetyl-DL-tryptophan prepared in step (1), 1536kg of water and 192kg of sodium hydroxide to the splitting reactor, raise the temperature to 80°C for 2 hours, then cool to 30°C Below ℃, centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com