Waterborne forest negative oxygen ion exterior wall coating and preparation method thereof

A technology of negative oxygen ions and exterior wall coatings, applied in antifouling/underwater coatings, anti-corrosion coatings, coatings, etc., can solve problems such as inability to continuously release negative oxygen ions, and achieve excellent alkali resistance, air Fresh, maintenance recoatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A kind of preparation method of waterborne forest negative oxygen ion exterior wall paint, comprises steps:

[0038] A, under stirring state, mix a part of deionized water, hydroxyethyl cellulose and pH regulator; under new stirring state, mix a part of deionized water, hydroxyethyl cellulose and pH regulator to obtain Hydroxyethyl cellulose liquid;

[0039] B. Under stirring, mix the hydroxyethyl cellulose solution, dispersant and a part of the defoamer to obtain the defoamer;

[0040] C. In a stirring state, mix the defoaming liquid, titanium dioxide, superfine ground calcium carbonate and negative oxygen ion additives to obtain a negative oxygen ion mixture;

[0041] D. Under stirring, mix the negative oxygen ion mixture, hydrophobic agent, anti-mold agent, preservative, pure acrylic emulsion, associative thickener, film-forming aid and another part of defoamer to obtain a water-based The rough product of forest negative oxygen ion exterior wall paint;

[0042] E....

Embodiment 1

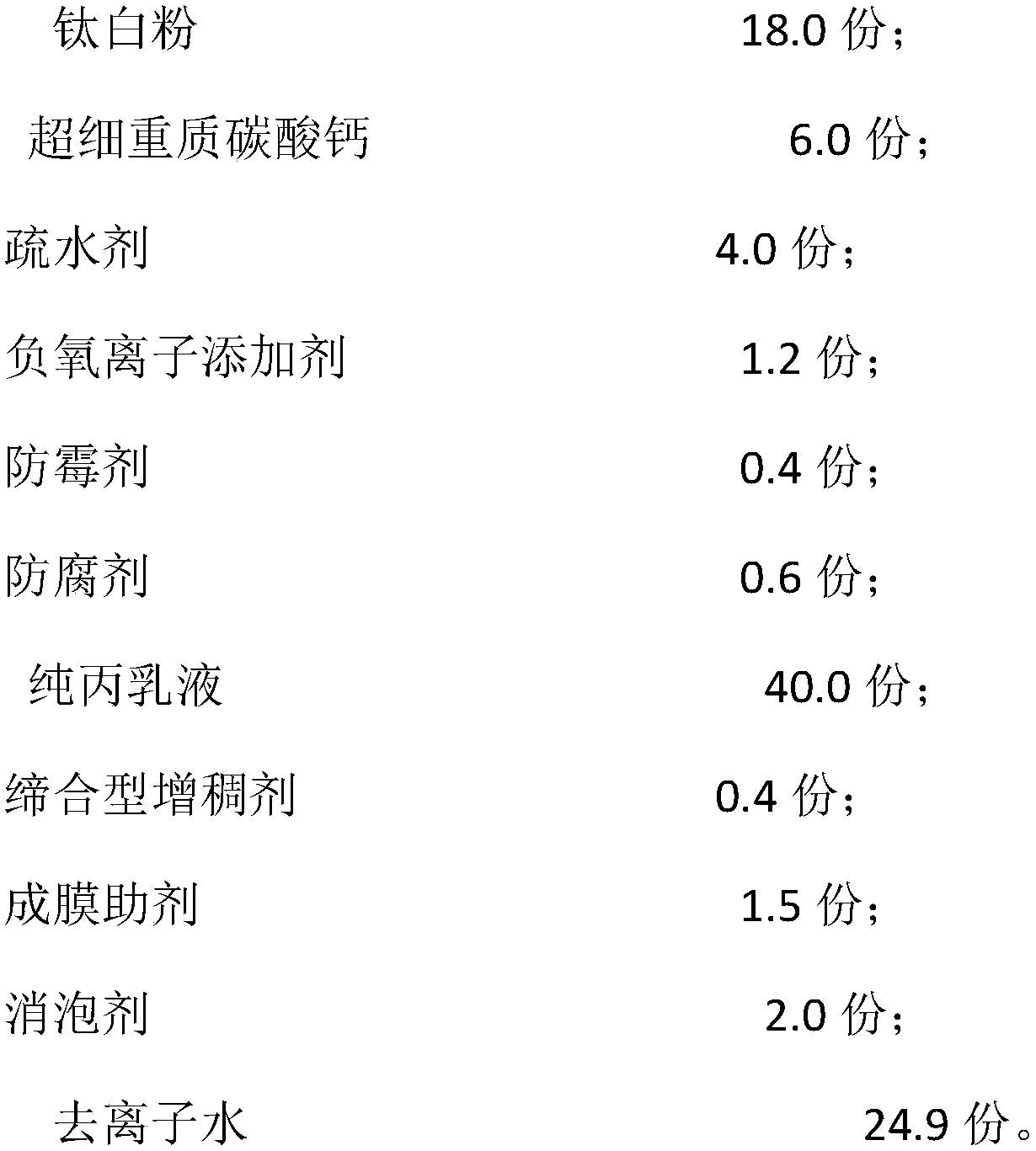

[0049] A kind of water-based forest negative oxygen ion exterior wall paint, comprises the raw material of following parts by weight:

[0050]

[0051] A kind of preparation method of waterborne forest negative oxygen ion exterior wall paint, comprises steps:

[0052] A, under stirring state, mix a part of deionized water, hydroxyethyl cellulose and pH regulator; under new stirring state, mix a part of deionized water, hydroxyethyl cellulose and pH regulator to obtain Hydroxyethyl cellulose liquid;

[0053] B. Under stirring, mix the hydroxyethyl cellulose solution, dispersant and a part of the defoamer to obtain the defoamer;

[0054] C. In a stirring state, mix the defoaming liquid, titanium dioxide, superfine ground calcium carbonate and negative oxygen ion additives to obtain a negative oxygen ion mixture;

[0055] D. Under stirring, mix the negative oxygen ion mixture, hydrophobic agent, anti-mold agent, preservative, pure acrylic emulsion, associative thickener, fil...

Embodiment 2

[0059] A kind of water-based forest negative oxygen ion exterior wall paint, comprises the raw material of following parts by weight:

[0060]

[0061]

[0062] A kind of preparation method of waterborne forest negative oxygen ion exterior wall paint, comprises steps:

[0063] A, under stirring state, mix a part of deionized water, hydroxyethyl cellulose and pH regulator; under new stirring state, mix a part of deionized water, hydroxyethyl cellulose and pH regulator to obtain Hydroxyethyl cellulose liquid;

[0064] B. Under stirring, mix the hydroxyethyl cellulose solution, dispersant and a part of the defoamer to obtain the defoamer;

[0065] C. In a stirring state, mix the defoaming liquid, titanium dioxide, superfine ground calcium carbonate and negative oxygen ion additives to obtain a negative oxygen ion mixture;

[0066] D. Under stirring, mix the negative oxygen ion mixture, hydrophobic agent, anti-mold agent, preservative, pure acrylic emulsion, associative th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com