A kind of preparation method of plastic wood profile with high flame retardant performance

A technology with high flame retardancy and high performance, which is applied in the field of plastic wood profiles and its preparation, can solve the problems of not meeting the requirements of profile products, poor fluidity of plastic wood profiles, and unstable extrusion melt, etc., to achieve good appearance and performance, The product has superior mechanical properties and enhanced melt fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

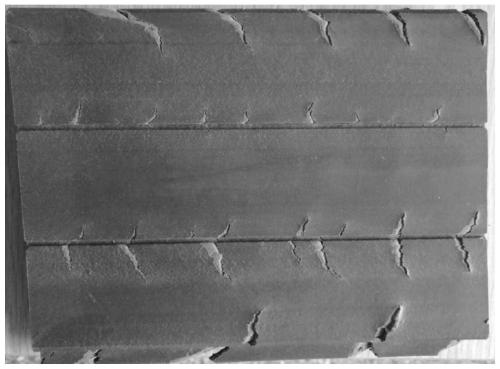

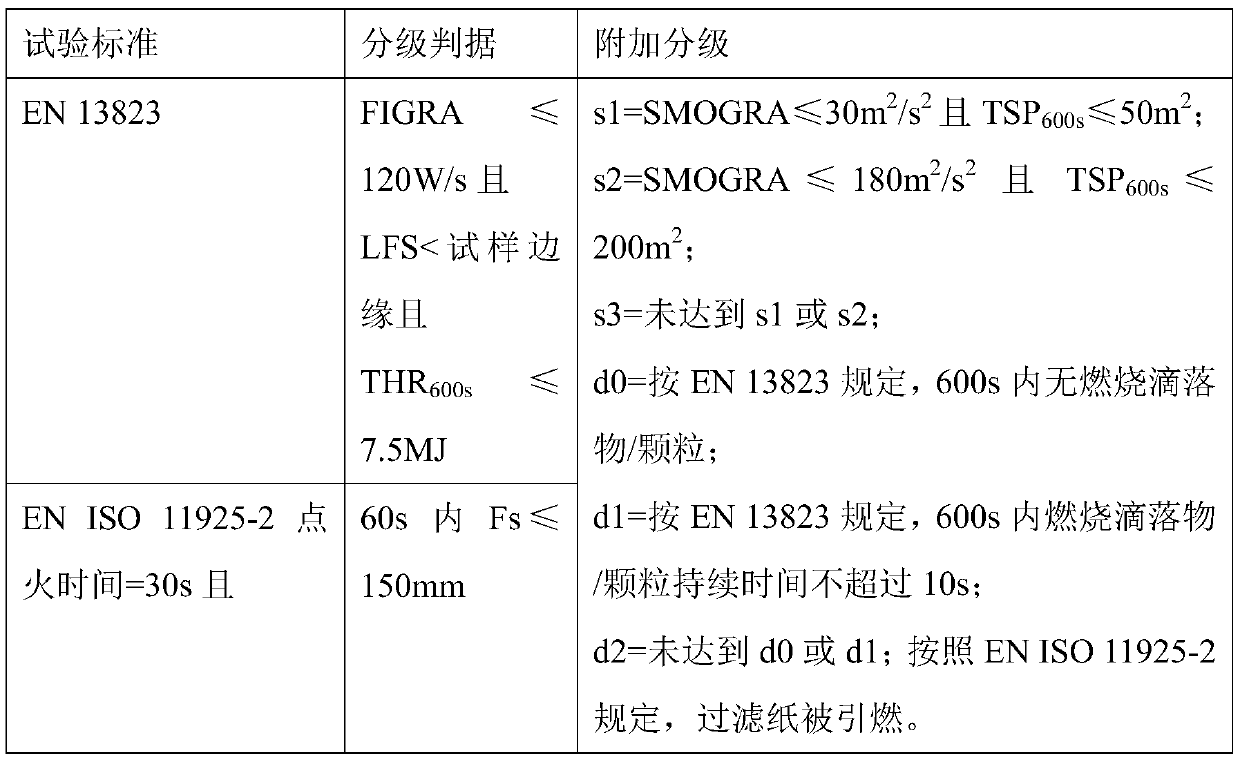

Image

Examples

Embodiment 1

[0040] A method for preparing a polyethylene-based plastic wood profile with high flame retardancy, comprising the following steps:

[0041] (1) Modification treatment of the flame retardant system: first, 20 parts of polyphosphazene and 80 parts of magnesium hydroxide with a particle size of 40um are placed in a ball mill, and 8 parts of 0.08mol / L maleic anhydride / ethanol solution are sprayed On the filler surface, grind for 30min.

[0042](2) Treatment and modification of wood powder: first dry the wood powder to a water content of 1.85%, then place 100 parts of wood powder, 5 parts of glyceryl ether-based silicone oil, and 1 part of alkylphenol polyoxyethylene ether in 100-110 In a high-speed mixer at ℃, the speed is 450r / min, and the mixture is mixed for 20 minutes;

[0043] (3) Mixing and granulation: first add 30 parts of recycled polyethylene plastic granules, 40 parts of modified flame retardant system, and 5 parts of SEBS elastomer into the mixer, and pre-mix for 30 ...

Embodiment 2

[0048] A method for preparing a polypropylene-based plastic wood profile with high flame retardancy, comprising the following steps:

[0049] (1) Modification treatment of flame retardant system: first, 30 parts of polyphosphazene and 70 parts of aluminum hydroxide with a particle size of 40um are placed in a ball mill, and 5 parts of 0.09mol / L maleic anhydride / ethanol solution are sprayed On the filler surface, grind for 25min.

[0050] (2) Treatment and modification of wood powder: first dry the wood powder to a water content of 2.28%, then place 100 parts of wood powder, 7 parts of glyceryl ether-based silicone oil, and 2 parts of alkylphenol polyoxyethylene ether in 100-110 In a high-speed mixer at ℃, the speed is 400r / min, and the mixture is mixed for 30min;

[0051] (3) Mixing and granulation: first add 30 parts of recycled polypropylene plastic granules, 25 parts of modified flame retardant system, and 1 part of SEBS elastomer into the mixer, and pre-mix for 20 minutes...

Embodiment 3

[0056] A method for preparing a polyethylene-polypropylene-based plastic-wood profile with high flame retardancy, comprising the following steps:

[0057] (1) Modification treatment of the flame retardant system: first, 25 parts of polyphosphazene, 35 parts of aluminum hydroxide with a particle size of 30um, and 35 parts of magnesium hydroxide with a particle size of 30um are placed in a ball mill, and 0.09mol / L of Spray 8 parts of maleic anhydride / ethanol solution on the filler surface and grind for 15 minutes.

[0058] (2) Treatment and modification of wood flour: first dry the wood flour to a water content of 2.52%, then place 100 parts of wood flour, 10 parts of glyceryl ether-based silicone oil, and 3 parts of alkylphenol polyoxyethylene ether in 100-110 In a high-speed mixer at ℃, the speed is 400r / min, and the mixture is mixed for 15 minutes;

[0059] (3) Mixing and granulation: first add 10 parts of recycled polyethylene plastic granules, 15 parts of recycled polyprop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com