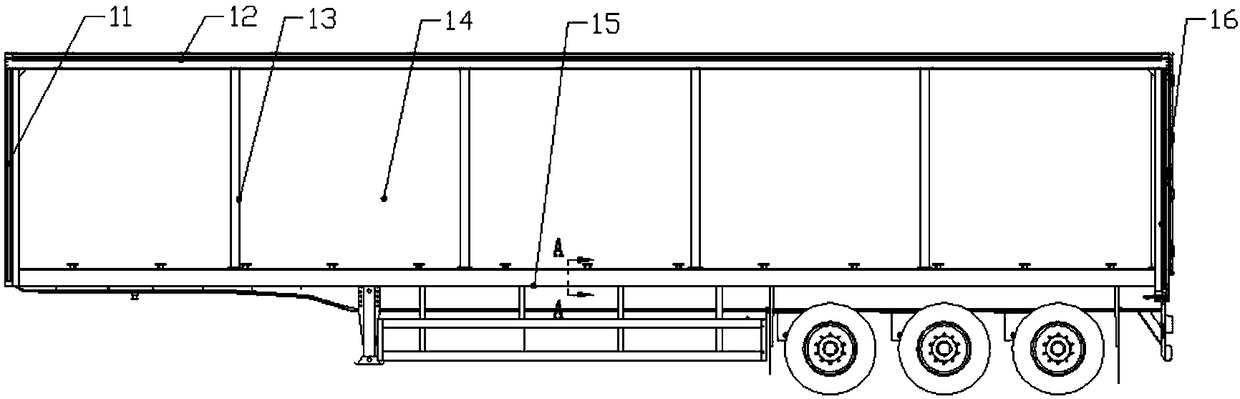

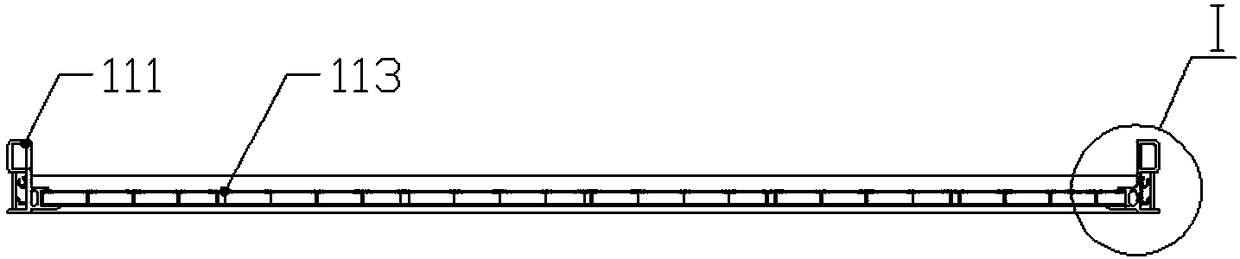

Aluminum-alloy lateral-curtain-semitrailer profile standing column and front box assembly thereof

An aluminum alloy and semi-trailer technology, applied in the direction of tractor-trailer combination, motor vehicles, vehicle parts, etc., can solve the problems of poor corrosion resistance and heavy column weight, achieve the effect of reducing column weight and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Such as Figure 5 As shown, an aluminum alloy side curtain semi-trailer profile column, its structure includes profile column characteristic surface 1 31, profile column characteristic surface 2 32, profile column characteristic surface 3 33, profile column characteristic surface 4 34, profile column characteristic surface 5 35. Profile column characteristic surface six 36, profile column characteristic surface seven 38, profile column characteristic surface eight 311; profile column characteristic surface one 31, profile column characteristic surface two 32, profile column characteristic surface three 33, profile column characteristic surface Four 34, profile column characteristic surface five 35, profile column characteristic surface six 36, profile column characteristic surface seven 38, profile column characteristic surface eight 311 structures are all made of aluminum alloy materials. This improvement reduces the weight of the column and improves the corrosion resi...

Embodiment 2

[0035] On the basis of the aluminum alloy side curtain semi-trailer profile column described in Example 1, the profile column characteristic surface one 31, the profile column characteristic surface two 32, the profile column characteristic surface three 33, the profile column characteristic surface four 34, Profile column characteristic surface five 35, profile column characteristic surface six 36, profile column characteristic surface seven 38, and profile column characteristic surface eight 311 are integrally formed. This improvement reduces the number of connections, does not require welding, avoids welding defects, and simplifies the column structure.

Embodiment 3

[0037] On the basis of the aluminum alloy side curtain semi-trailer profile column described in Example 2, the profile column characteristic surface one 31, the profile column characteristic surface two 32, the profile column characteristic surface three 33, the profile column characteristic surface four 34, Profile column characteristic surface five 35, profile column characteristic surface six 36, profile column characteristic surface seven 38, profile column characteristic surface eight 311 The molding process of the connection between the structures is an aluminum extrusion process. This improvement improves the section strength of the component, improves the machining accuracy, and simplifies the production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com