Whole vehicle thermal management system of pure electric vehicle and management method

A pure electric vehicle and management system technology, applied in the field of pure electric vehicle thermal management, can solve the problems of increasing the layout pressure of the whole vehicle, waste of electric energy, and different cooling effects of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

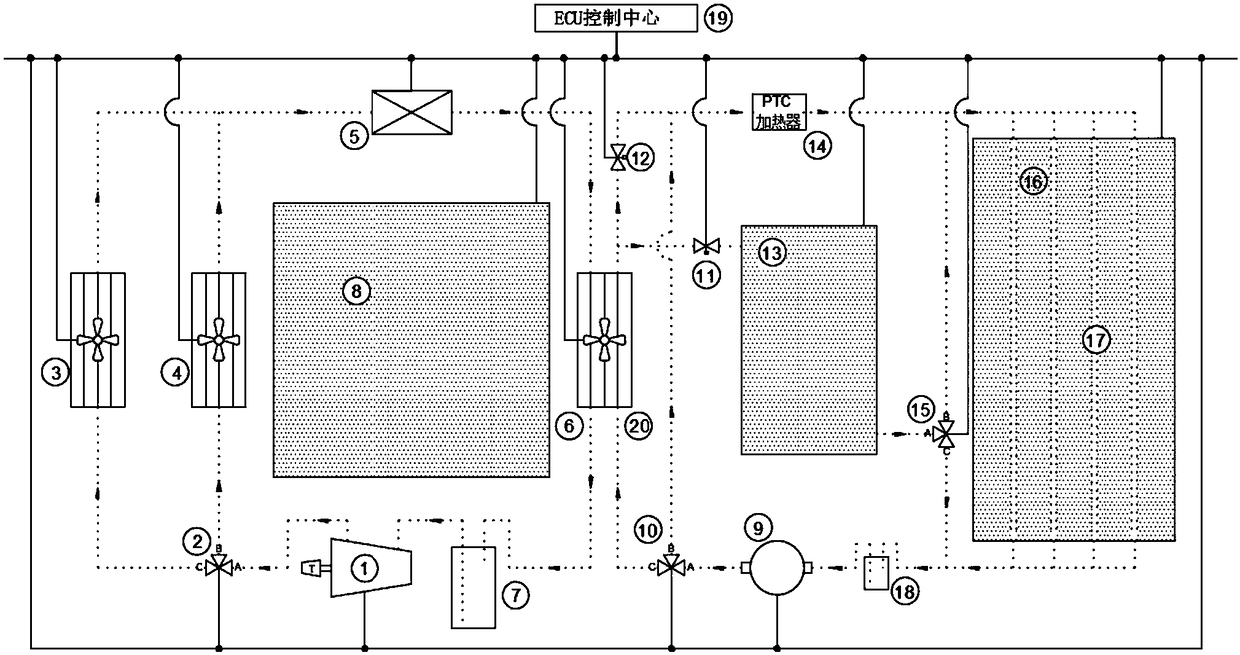

[0059] The following are specific embodiments of the present invention and in conjunction with the attached figure 1 , to further describe the technical solutions of the present invention, but the present invention is not limited to these examples.

[0060] A pure electric vehicle thermal management system, the pure electric vehicle has a heat pump air conditioning system 8, a battery pack thermal management system 16 and an electronically controlled cooling system 13; the system includes a heat pump air conditioning refrigerant liquid circulation circuit, a battery The coolant liquid circulation circuit of the thermal management system and the electronic control cooling system and the ECU control center; the two major liquid circulation circuits are coupled at the first evaporator 6 and the second evaporator 20, and the first evaporator 6 and the second evaporator The two internal pipelines for entering and exiting the liquid of the device 20 are independent, and the flow dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com