Energy-saving production device for quality edible alcohol

A technology of edible alcohol and production equipment, which is applied in the chemical industry, the preparation of organic compounds, climate sustainability, etc., and can solve the problems of waste of heat sources, high steam consumption, and unreasonable use of heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

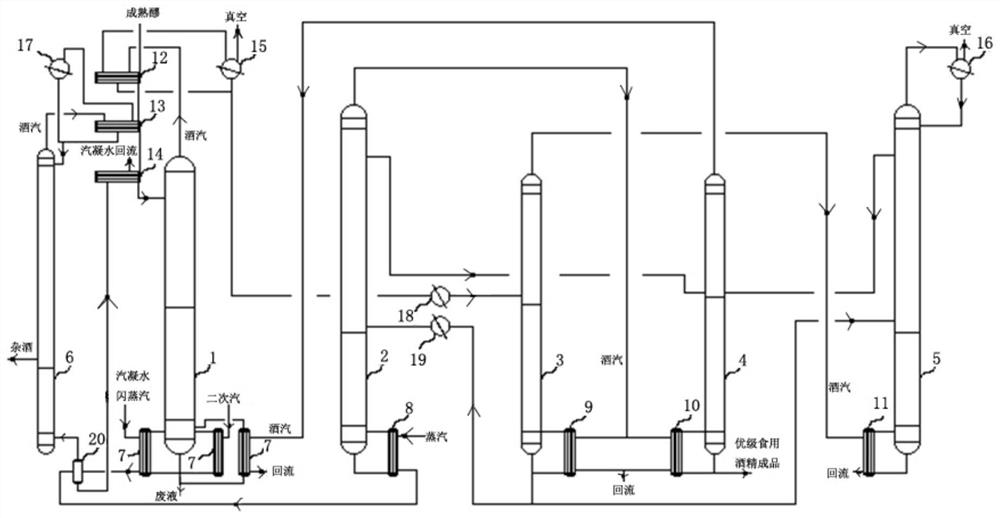

[0030] This embodiment provides an energy-saving production device for high-grade edible alcohol, such as figure 1 As shown, it comprises a crude distillation tower 1, a rectification tower 2, a negative pressure rectification tower 5, a water washing tower 3, a methanol tower 4 and a recovery tower 6; the crude distillation tower 1 is connected to the water washing tower 3, and the water washing Tower 3 is connected to described rectifying tower 2 and negative pressure rectifying tower 5 respectively; Described rectifying tower 2 and negative pressure rectifying tower 5 are all connected to described recovery tower 6;

[0031] The reboiler 7 of the crude distillation tower receives the alcohol vapor from the top of the methanol tower 4, the condensed water flash steam of other processes after treatment, the distillation process and other processes, and is used for the indirect distillation of the crude distillation tower. Heating; the alcohol vapor at the top of the methanol ...

Embodiment 2

[0047] This embodiment provides a method for producing high-grade edible alcohol using the high-grade edible alcohol energy-saving production device described in Example 1, such as figure 1 As shown, the specific process is:

[0048] The mature mash from fermentation is preheated successively through the primary preheater 12, the secondary preheater 13 and the tertiary preheater 14, and the preheating medium of the primary preheater 12 is the crude distillation tower top wine steam, the preheating medium of the secondary preheater 13 is the recovery tower top wine vapor, and the preheating medium of the three-stage preheater 14 is condensate water flash steam;

[0049]The preheated mature mash enters the degassing section of the crude distillation tower 1, and the mash after removing carbon dioxide gas and low-boiling impurities enters the stripping section of the crude distillation tower 1, and the distilled wine vapor enters the first stage from the top of the tower. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com