A kind of anti-moisture absorption adhesive and its preparation method and application

A binder and silane coupling agent technology, which is applied in the field of casting sand binder preparation, can solve the problems of increasing the complexity of the process and operation, deteriorating the working environment, and flying dust, so as to improve working conditions, protect the environment, Effect of improving room temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

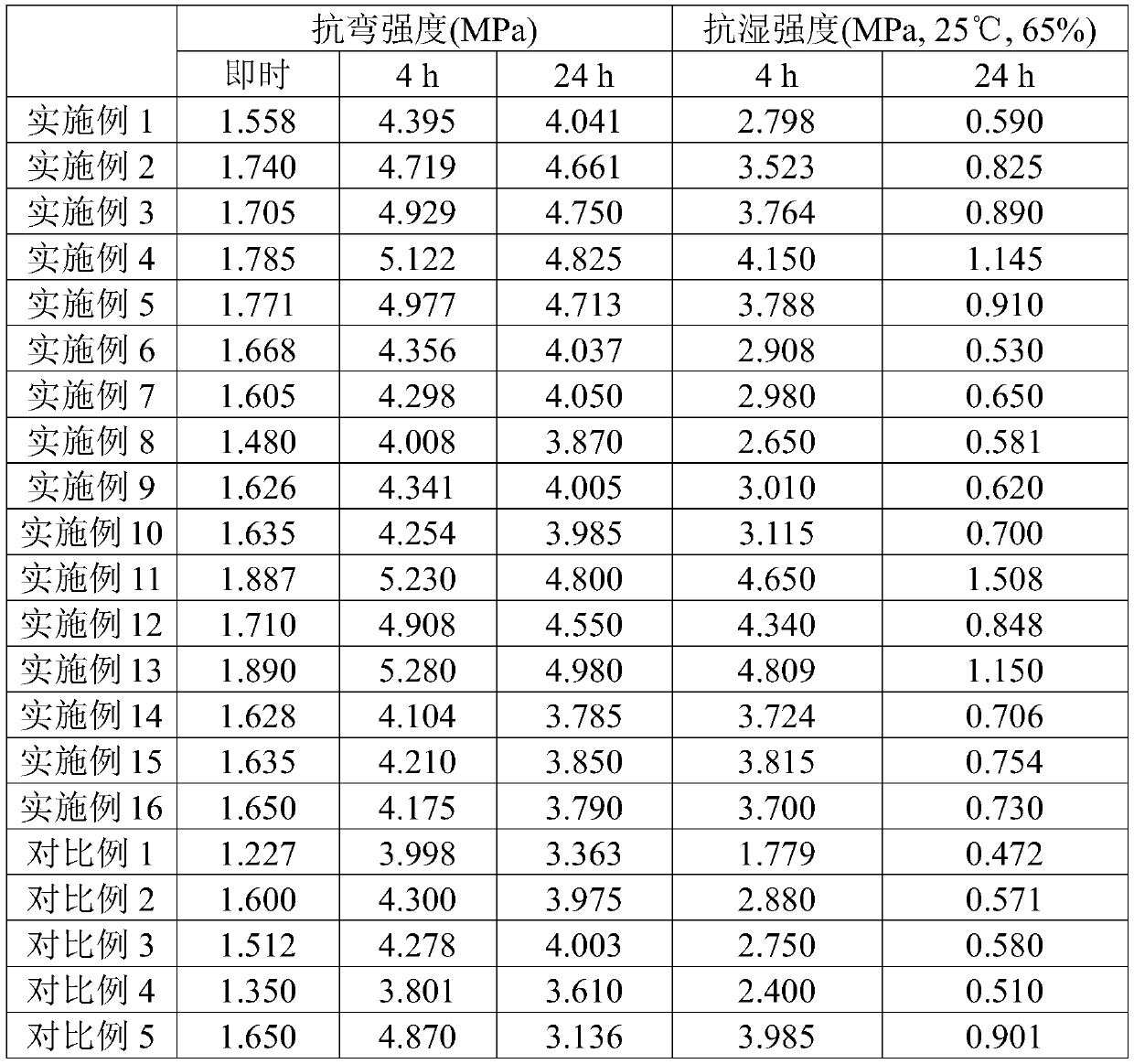

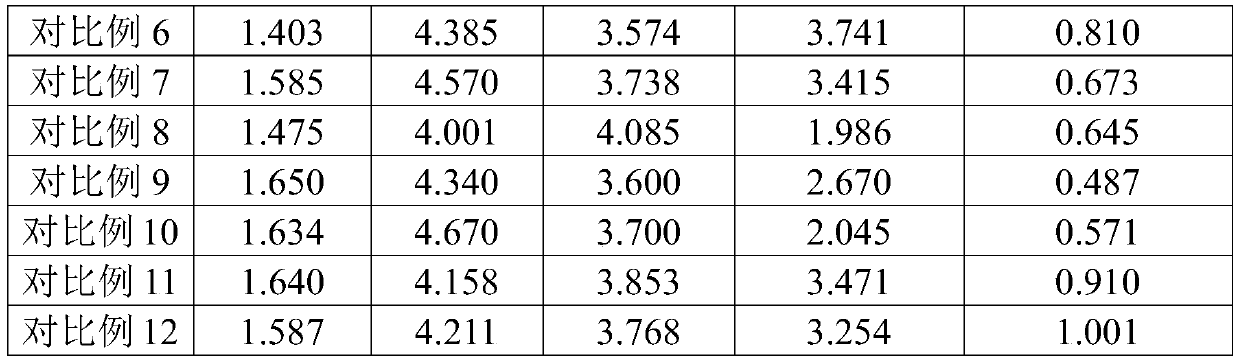

Examples

Embodiment 1

[0046] The preparation method of the binding agent provided in this embodiment is as follows:

[0047] Add 200g of water glass into a three-necked flask, place it in an oil bath at 90°C, start stirring, slowly add 6g of amorphous silica, 4g of silane coupling agent, heat and stir for 2 hours to obtain a binder.

[0048] Among them, the modulus of water glass is 2.3, and the density is 1.6g / cm 3 , Amorphous silica is prepared by pyrolysis method, with a particle size of 5 μm; the silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane.

Embodiment 2

[0050] The preparation method of the binding agent provided in this embodiment is as follows:

[0051] Add 200g of water glass into a three-necked flask, place it in an oil bath at 90°C, start stirring, slowly add 6g of amorphous silica, 4g of silane coupling agent and 2g of sorbitol, heat and stir for 2 hours to obtain a binder.

[0052] Among them, the modulus of water glass is 2.3, and the density is 1.6g / cm 3 , Amorphous silica is prepared by pyrolysis method, with a particle size of 5 μm; the silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane.

Embodiment 3

[0054] The preparation method of the binding agent provided in this embodiment is as follows:

[0055] Add 200g of water glass into a three-necked flask, place it in an oil bath at 90°C, start stirring, slowly add 6g of amorphous silica, 4g of silane coupling agent and 4g of sorbitol, heat and stir for 2 hours to obtain a binder.

[0056] Among them, the modulus of water glass is 2.3, and the density is 1.6g / cm 3 , Amorphous silica is prepared by pyrolysis method, with a particle size of 5 μm; the silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com