Tone-up powder and preparation process thereof

A preparation process and a technology for no makeup, applied to the field of plain powder and its preparation technology, can solve the problems of insufficient moisturizing foundation, reduced skin water content, insufficiently uniform modification, etc., and achieves improved modification uniformity, fluffy and fine powder, and improved water resistance. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

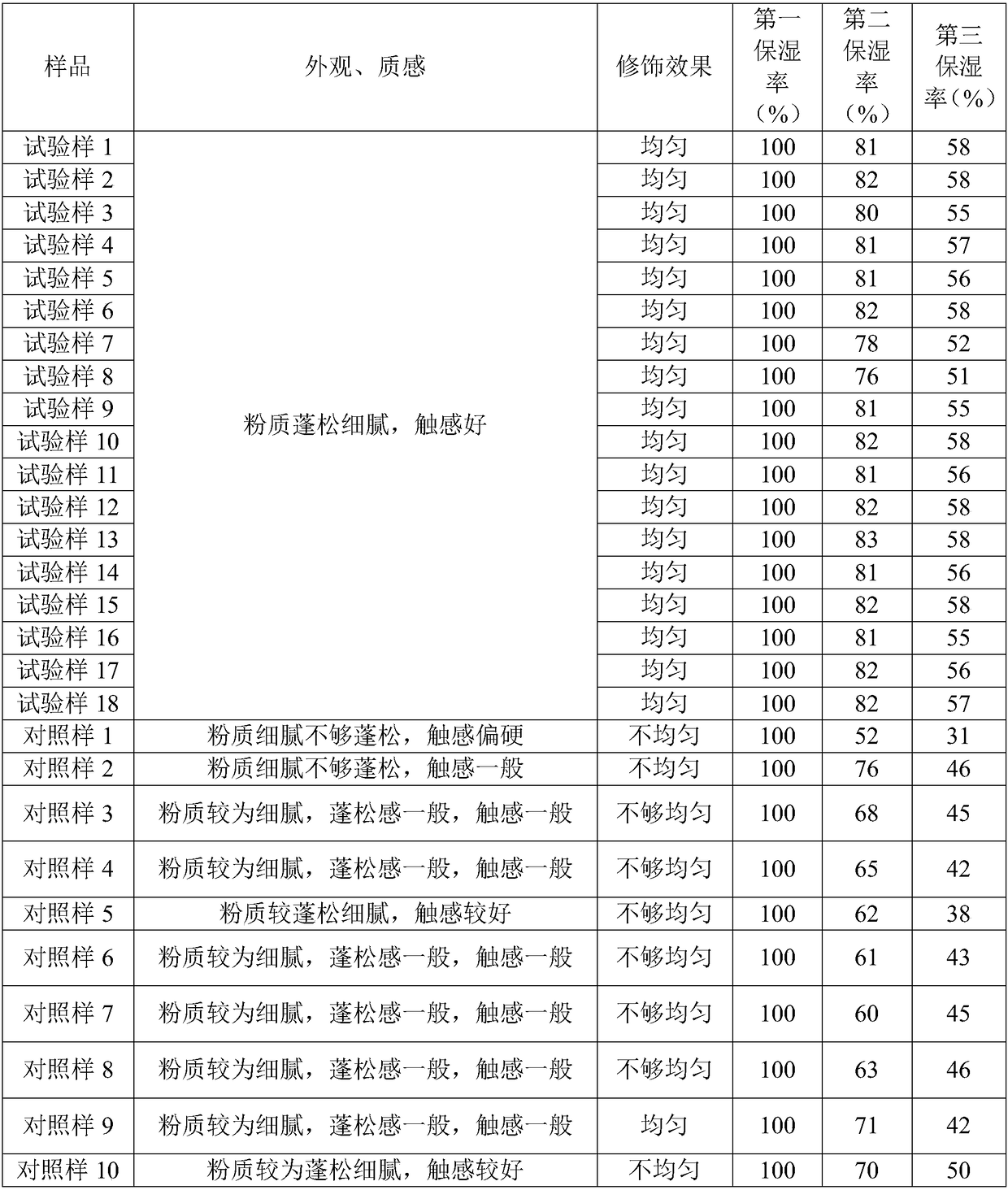

Examples

Embodiment 1

[0058] Embodiment 1: A plain face powder, the components included and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0059]A, heating deionized water, glycerin, polymethyl methacrylate, and emollient to 78°C, and uniformly mixing to form the first mixture;

[0060] B. Heat the first filler, the second filler, and the compounded colorant to 78°C and mix them thoroughly to obtain the second mixture;

[0061] C. Cool down the first mixture obtained in step A to 65°C, add it into the second mixture obtained in step B and cool down to 65°C, and mix thoroughly to obtain plain face powder.

[0062] Wherein, the first filler is composed of silica, polymethylsiloxane, talc, and triethoxyoctylsilane in a ratio of parts by weight of 7:3:2:3:1;

[0063] The second filler is composed of polytetrafluoroethylene, mica and polydimethylsiloxane with a ratio of parts by weight of 5:2.2:1.2;

[0064] The emollient is composed of butane...

Embodiment 2-8

[0066] Example 2-8: a plain face powder, the difference from Example 1 is that the components included and their corresponding parts by weight are shown in Table 1, and methylparaben is added in step C.

[0067] Components included in Table 1 Embodiment 1-8 and their corresponding parts by weight

[0068]

Embodiment 9

[0069] Embodiment 9: a kind of plain face powder, the difference from embodiment 2 is that the first filler is composed of silica, polymethylsiloxane, talcum powder, three Ethoxycaprylylsilane composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com