Processing method of low-sugar preserved dragon fruit peels

A technology of pitaya peel and a processing method, which is applied in the confectionery industry, confectionery, food preservation and other directions, can solve the problems of reducing the nutritional value of the product, destroying the nutritional components, etc., and achieves the preservation of nutrition and color, no cracking, and simple preparation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

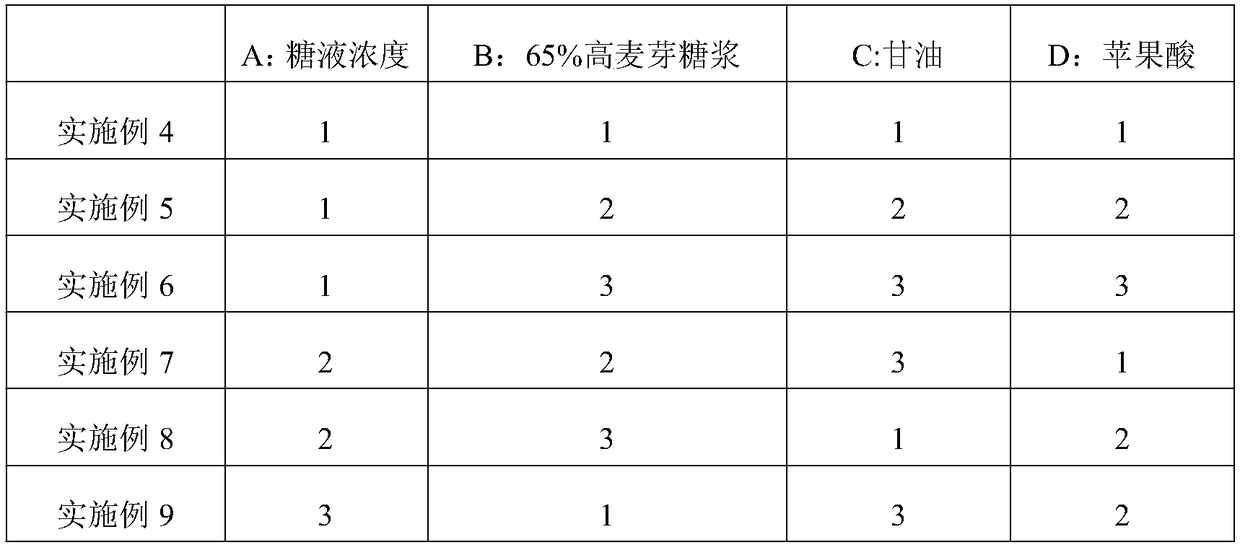

Examples

Embodiment 1

[0023] A method for processing low-sugar dragon fruit peel and preserved fruit, comprising the following preparation steps:

[0024] 1) Cleaning: Wash the dragon fruit peel, remove the scales, cut into strips for later use;

[0025] 2) Disinfection: soak the peel strip obtained in step 1) in the disinfectant solution, and disinfect;

[0026] 3) Soak in sugar: soak the sterilized peel in step 2) in the compound sugar solution;

[0027] 4) Drying: dry the peel after soaking in sugar, and package it to get it.

[0028] Described disinfectant is the chlorine dioxide solution that mass concentration is 100mg / L.

[0029] The disinfection is to soak the peel in the disinfectant solution for 90s.

[0030] The compound sugar solution contains 65% high maltose syrup with a mass fraction of 10%, edible glycerin with a mass fraction of 0.8%, malic acid with a mass fraction of 0.4%, and a sugar content of 30°BX.

[0031] The sugar dipping is to soak in the compound sugar liquid for 24 ...

Embodiment 2

[0034] A method for processing low-sugar dragon fruit peel and preserved fruit, comprising the following preparation steps:

[0035] 1) Cleaning: Wash the dragon fruit peel, remove the scales, cut into strips for later use;

[0036] 2) Disinfection: soak the peel strip obtained in step 1) in the disinfectant solution, and disinfect;

[0037] 3) Soak in sugar: soak the sterilized peel in step 2) in the compound sugar solution;

[0038] 4) Drying: dry the peel after soaking in sugar, and package it to get it.

[0039] Described disinfectant is the chlorine dioxide solution that mass concentration is 150mg / L.

[0040] The disinfection is to soak the peel in the disinfectant solution for 60s.

[0041] The compound sugar solution contains 65% high maltose syrup with a mass fraction of 10%, edible glycerin with a mass fraction of 0.8%, malic acid with a mass fraction of 0.4%, and a sugar content of 30°BX.

[0042] The sugar dipping is to soak in the compound sugar liquid for 24 ...

Embodiment 3

[0045] A method for processing low-sugar dragon fruit peel and preserved fruit, comprising the following preparation steps:

[0046] 1) Cleaning: Wash the pitaya skin, remove the scales, cut into strips for later use;

[0047] 2) Disinfection: soak the peel strip obtained in step 1) in the disinfectant solution, and disinfect;

[0048] 3) Soak in sugar: soak the sterilized peel in step 2) in the compound sugar solution;

[0049] 4) Drying: dry the peel after soaking in sugar, and package it to get it.

[0050] Described disinfectant is the chlorine dioxide solution that mass concentration is 200mg / L.

[0051] The disinfection is to soak the peel in the disinfectant solution for 30s.

[0052] The compound sugar solution contains 65% high maltose syrup with a mass fraction of 10%, edible glycerin with a mass fraction of 0.8%, malic acid with a mass fraction of 0.4%, and a sugar content of 30°BX.

[0053] The sugar dipping is to soak in the compound sugar liquid for 24 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com