Lithium iron phosphate composite material with high compaction density and method for preparing lithium iron phosphate composite material

A technology of lithium iron phosphate and composite materials, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low compaction density, high compaction density of composite materials, poor rate performance, etc., and achieve improved compaction The effect of improving density and electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

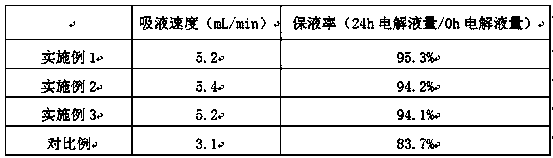

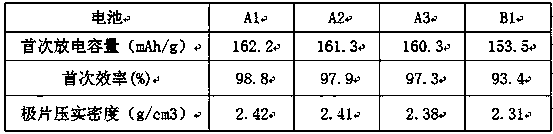

Examples

Embodiment 1

[0024] 10.4g LiH 2 PO4, 40.4gFe(NO3) 3 9H 2 O was dissolved in 295ml of N,N-dimethylformamide and stirred evenly to obtain a lithium iron phosphate precursor solution with a concentration of 10%, and then 500ml of a graphene oxide solution with a concentration of 5mg / mL was added, filtered, and vacuum-dried at 80°C. 800 high temperature sintering for 2 hours to obtain graphene / lithium iron phosphate material A;

[0025] After that, the lithium titanate was placed in a gas-phase evaporation furnace, and the electron beam evaporation method was used (parameters: vacuum degree 1.0×10 -3 Pa, temperature 150°C, electron gun acceleration voltage 4kV, electron beam current 20mA, oxygen flow rate 18sccm, time ion beam current 30mA, time 40min), so that lithium titanate is deposited on the surface of material A, and graphene / iron phosphate is obtained after cooling Lithium / lithium titanate composite material B, the deposition thickness is 100nm; after that, melamine cyanurate is de...

Embodiment 2

[0027] 10.4g LiH 2 PO4, 23.3g FeC 6 h 5 o 7 ·5H 2 O was dissolved in 1201ml of N,N-dimethylformamide and stirred evenly to obtain a 2% lithium iron phosphate precursor solution, and then 500ml of graphene oxide solution with a concentration of 1mg / mL was added, then filtered, vacuum dried at 80°C, and heated at 800°C Sintering for 2h to obtain graphene / lithium iron phosphate material A;

[0028] After that, lithium magnesium silicate is placed in a gas phase evaporation furnace, and the electron beam evaporation method is used (parameters: vacuum degree 1.0×10 -3 Pa, temperature 150°C, electron gun acceleration voltage 4kV, electron beam current 10mA, oxygen flow rate 15sccm, time ion beam current 20mA, time 10min), so that magnesium lithium silicate is deposited on the surface of material A, and graphene / phosphoric acid is obtained after cooling Lithium iron / lithium titanate composite material B, with a deposition thickness of 50nm; then, by chemical vapor phase method, ...

Embodiment 3

[0030] 10.4g LiH 2 PO4, 23.3g FeC 6 h 5 o 7 ·5H 2 O was dissolved in 90ml of N,N-dimethylformamide and stirred evenly to obtain a 20% lithium iron phosphate precursor solution, and then 500ml of graphene oxide solution with a concentration of 10mg / mL was added, then filtered, vacuum-dried at 80°C, and heated at 800°C Sintering for 2h to obtain graphene / lithium iron phosphate material A;

[0031] After that, lithium vanadate is placed in a gas phase evaporation furnace, and the electron beam evaporation method is used (parameters: vacuum degree 1.0×10 -3 Pa, temperature 150°C, electron gun acceleration voltage 4kV, electron beam current 30mA, oxygen flow rate 20sccm, time ion beam current 40mA, time 60min), so that magnesium lithium silicate is deposited on the surface of material A, and graphene / phosphoric acid is obtained after cooling Iron lithium / lithium titanate composite material B, with a deposition thickness of 200nm; then, by chemical vapor phase method, pentaery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com