Flue gas residual heat utilizing method for copper smelting furnace through dust remover with exhaust funnel

A flue gas waste heat and exhaust stack technology, which is applied in the direction of furnaces, waste heat treatment, furnace components, etc., can solve the problems of high investment costs, large floor space, and high resistance, so as to reduce operating costs, reduce floor space, and alleviate The effect of sudden ups and downs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

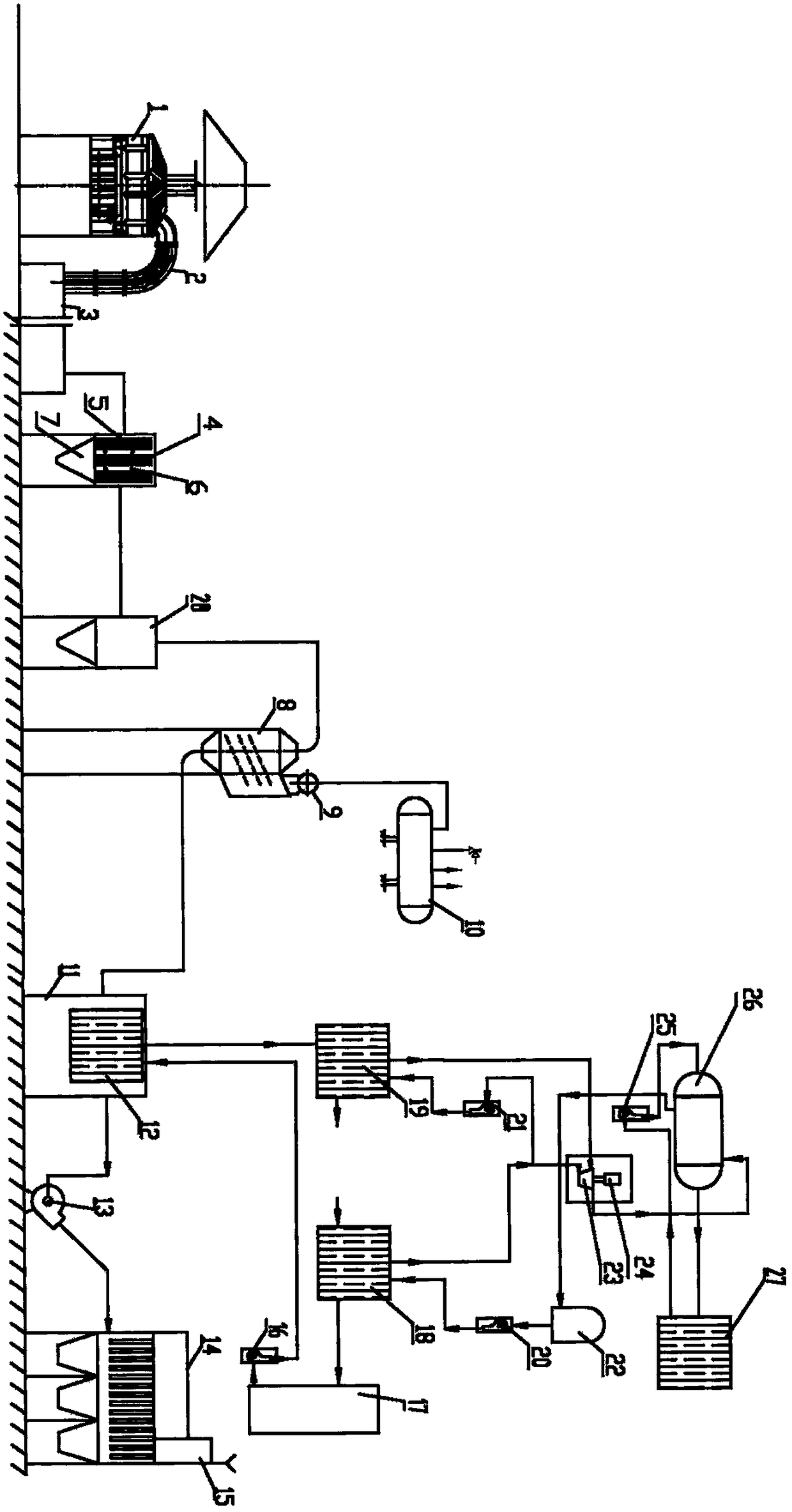

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] Such as figure 1 Shown: a kind of dedusting device of the present invention has the copper smelting furnace flue gas waste heat utilization method step of exhaust pipe as follows:

[0023] 35t / h copper smelting furnace 1 flue gas flow rate 22×10 4 N m 3 / h, temperature 750℃, dust concentration 15g / Nm 3 It is discharged from the furnace, mixed with cold air through the water-cooled flue 2, and enters the combustion settling chamber 3 after burning carbon monoxide gas; The cold wind finally burns carbon monoxide gas, and the flue gas from the combustion settling chamber 3 enters the heat storage homogenizer 4, and the heat storage homogenizer 4 includes a carbon-silicon composite material heat storage body 5, a shock wave ash cleaning device 6 and The ash hopper 7, the shock wave cleaning device 6 is arranged between the carbon-silicon composite regenerators 5 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com