A high temperature sintering furnace

A high-temperature sintering and furnace body technology, applied in the field of high-temperature processing, can solve the problem that the sintering furnace cannot reach the required high temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

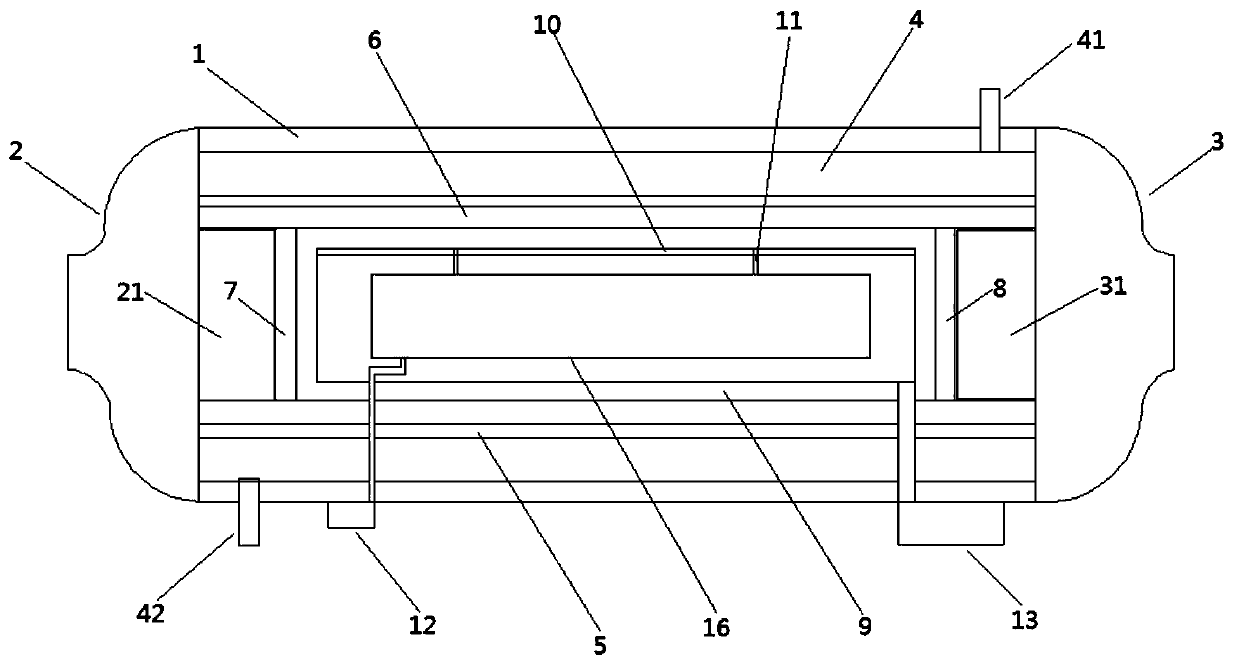

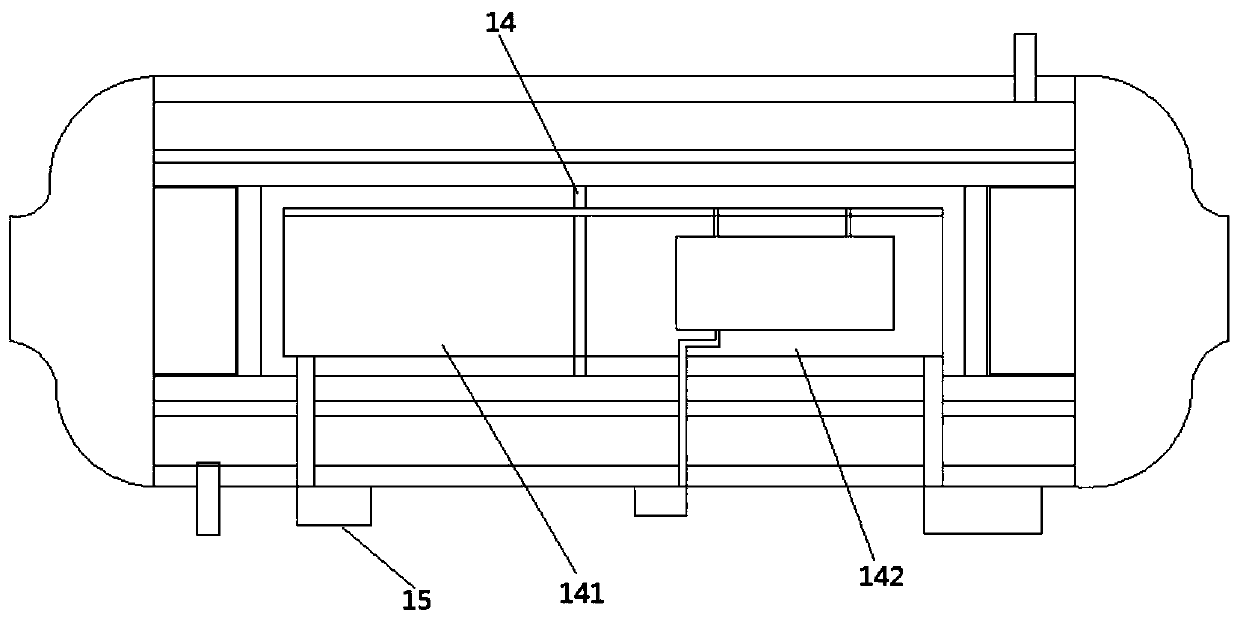

[0044] see figure 1 , a schematic diagram of the structure of a high-temperature sintering furnace.

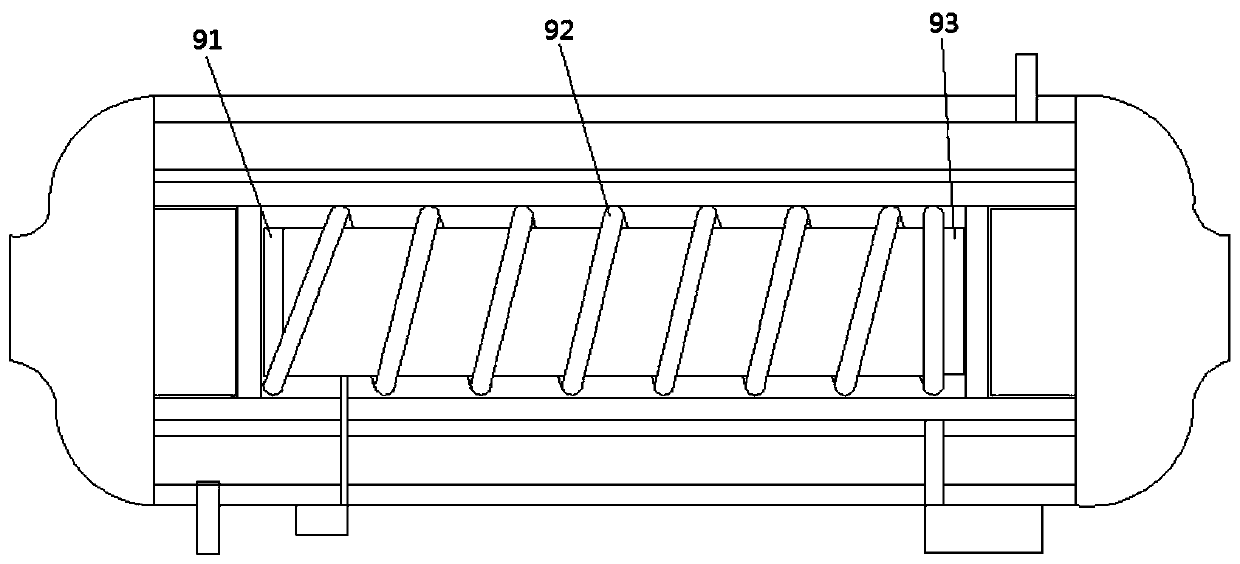

[0045] This embodiment provides a high-temperature sintering furnace, including: a furnace body 1, a first head 2, a second head 3, a cooling layer 4, an outlet pipe 41, an inlet pipe 42, a second insulation layer 6, and a heating layer 9 , storage box 16, temperature detection device 12 and vacuum device 13, are characterized in that, also comprise: first pressure head 21, second pressure head 31, heat insulation layer 5, first insulation layer 7 and the 3rd insulation layer 8;

[0046] The furnace body 1 is cylindrical, and the two ends of the furnace body 1 are respectively provided with the first sealing head 2 and the second sealing head 3;

[0047] The first head 2 and the second head 3 are respectively provided with the first pressure head 21 and the second pressure head 31 extending into the interior of the furnace body 1;

[0048] The inside of the furnace body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com