Pipeline repair airbag and pipeline repair process using the pipeline repair airbag

A pipeline repair and air bag technology, which is applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of long curing time of epoxy resin and prolonged operation period, so as to shorten the repair period and shorten the curing time , The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

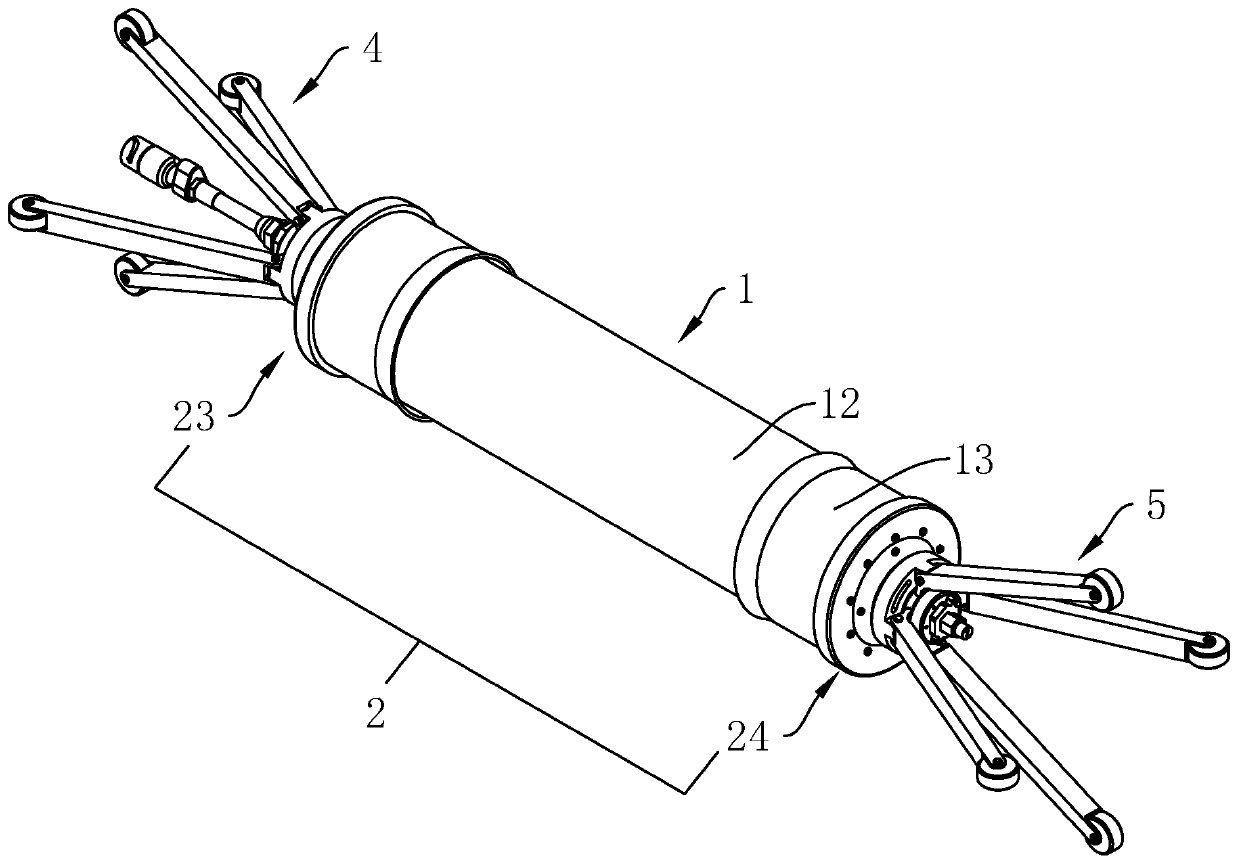

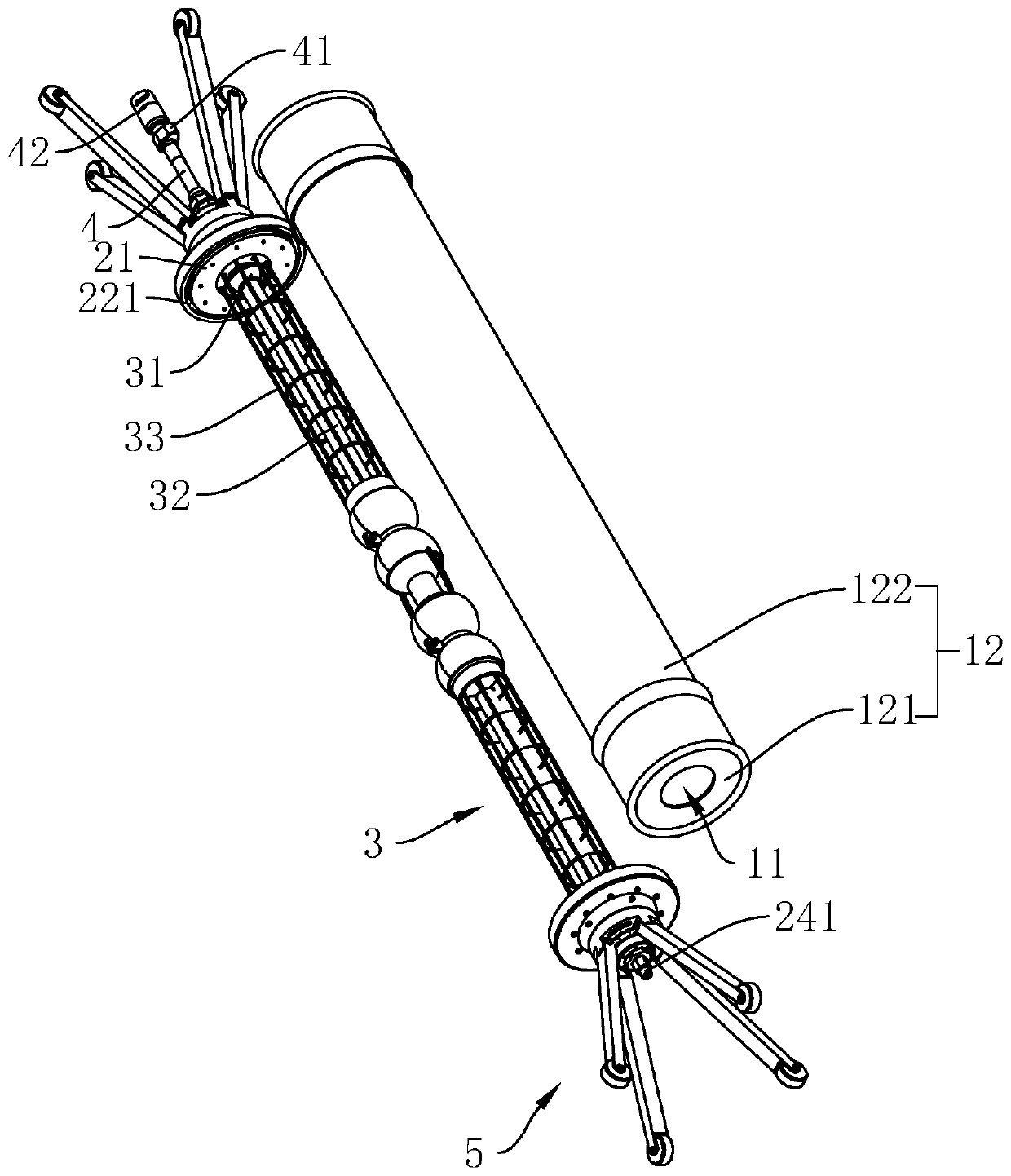

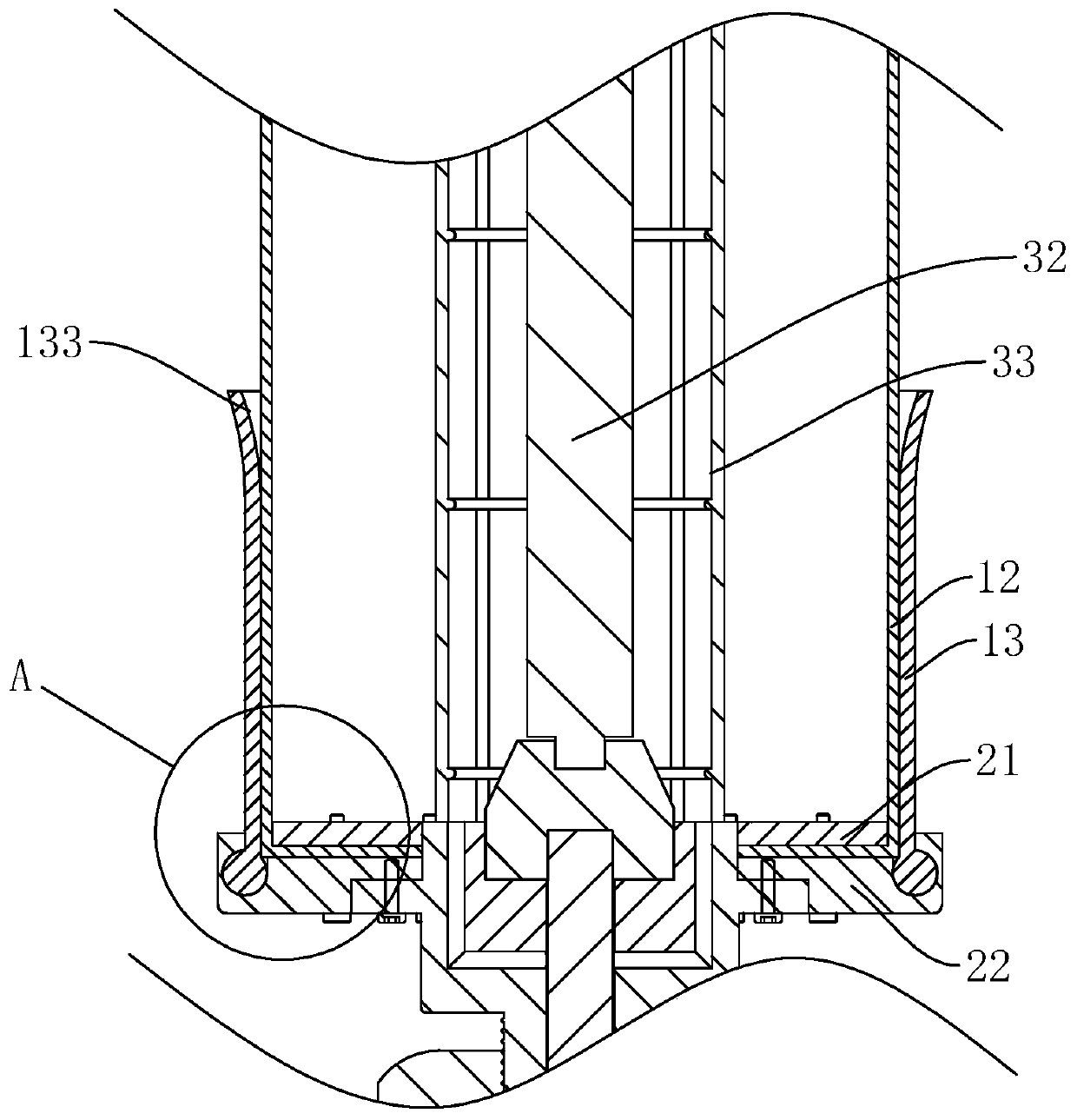

[0051] See figure 1 with figure 2 , A pipeline repair airbag, comprising two positioning frames 2 and an airbag body 1 connected to the two positioning frames 2. The airbag body 1 is made of a resin having translucency. The airbag body 1 and the two positioning frames 2 are enclosed to form an airbag cavity 11 in which the airbag body 1 is inflated by inflation. The positioning frame 2 is also connected with an ultraviolet lamp assembly 3 arranged inside the airbag cavity 11. The ultraviolet lamp assembly 3 includes an ultraviolet lamp body 32 connected to the positioning frame 2 through a lamp holder 31, and a protective cover 33 covering the outer periphery of the ultraviolet lamp body 32. The protective cover 33 is a wire mesh frame enclosed by iron wires, so that the ultraviolet Light can pass through the protective cover 33. The positioning frame 2 is also provided with a connecting tube 4 communicating with the airbag cavity 11, and the connecting tube 4 includes a ch...

Embodiment 2

[0058] See Figure 9 to Figure 13 , A pipeline repair process using the first embodiment includes the following steps:

[0059] Pipeline cleaning, see Picture 9

[0060] Step 1.1, determine the section of underground pipeline 91 that needs to be repaired, and set up road barriers 61 and warning signs 62 in the circumferential direction at the two drainage wells 6 that are located at both ends of the section of underground pipeline 91 and communicate with the section of underground pipeline 91. (For ease of presentation, The two drainage wells 6 are respectively named the first drainage well 63 and the second drainage well 64);

[0061] Step1.2, manually enter the first drainage well 63 and the second drainage well 64, and separate the underground pipe 91 in the section that needs to be repaired and the underground pipe 9 in the section that does not need to be repaired by a sealing plate 65 with a water hole;

[0062] Step1.3, park the dredging vehicle 71 near the first drainage wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com